HEADQUARTERS: Anderson Power Products®, 13 Pratts Junction Road, Sterling, MA 01564-2305 USA T:978-422-3600 F:978-422-3700

EUROPE: Anderson Power Products® Ltd., Unit 3, Europa Court, Europa Boulevard, Westbrook, Warrington, Cheshire, WA5 7TN United Kingdom T: +44 (0) 1925 428390 F: +44 (0) 1925 520203

ASIA / PACIFIC: IDEAL Anderson Asia Pacific Ltd., Unit 922-928 Topsail Plaza, 11 On Sum Street, Shatin N.T., Hong Kong T:+(852) 2636 0836 F:+(852) 2635 9036

CHINA: IDEAL Anderson Technologies (Shenzhen) Ltd., Block A8 Tantou Western Industrial Park, Songgang Baoan District, Shenzhen, PR. China 518105 T: +(86) 755 2768 2118 F: +(86) 755 2768 2218

TAIWAN: IDEAL Anderson Asia Pacific Ltd., Taiwan Branch, 4F.-2, No.116, Dadun 20th St., Situn District, Taichung City 407, Taiwan (R.O.C.) T: +(886) 4 2310 6451 F:+(886) 4 2310 6460

www.andersonpower.com

14820 1S6530 ASM-6PEXSPREC REV01

Extreme Power SPEC Pak

™

Receptacle

Page 2

PATENTS AND TRADEMARKS This product is Patent Pending.

Gasket

APP

Logo

Pin 2 - Relative

Pin 1

Pin 3

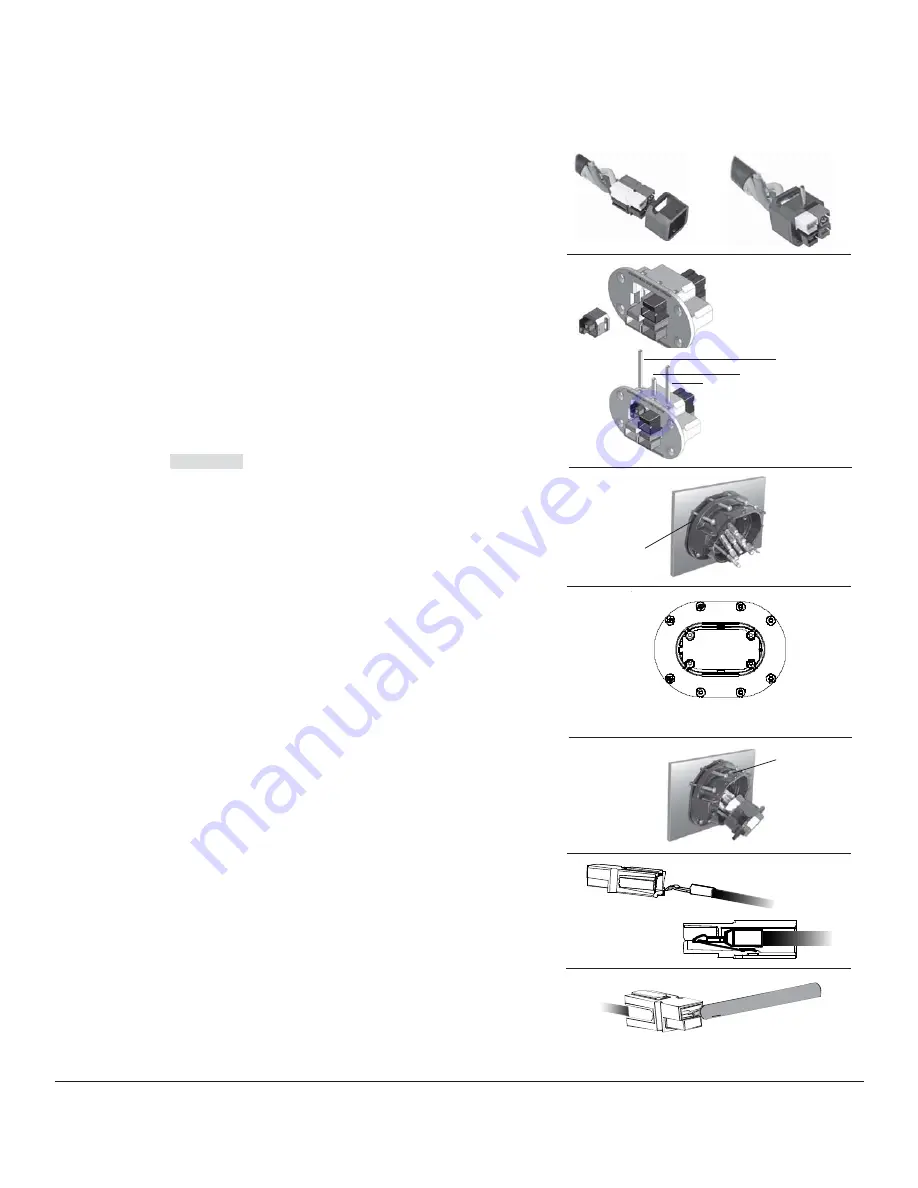

5. If using Powerpole 15/45 insert holder: block Powerpole

®

15/45 housings together, then insert

Powerpole block into 15/45 holder (See Figure 6a). Line up holes in Powerpole block with retaining pin

hole in holder. Insert retaining pin (See Figure 6b) until flush to complete assembly.

The PP15/45 holder insert should be installed from the front as shown in (See Figure 7a). Install

retaining pins in order shown relative to the PP15/45 holder insert (See Figure 7b). The short retaining

pin must be installed in the center hole first and be fully recessed into the Powerpole block. It should

not make contact with the large outer Powerpole Holder. Next install a long retaining pin into the hole

adjacent to the PP15/45 holder insert. Install the last long retaining pin. All long retaining pins should be

installed so they are flush with the large outer Powerpole Holder.

6. Prepare panel by cleaning and drying the panel surface. To ensure proper sealing, the panel

flatness should be 0.002 inches per inch.

7. Slide Panel Mount Gasket and Receptacle Shell onto wires. Panel Mount Gasket should be between

panel and rear of Receptacle Shell (See Figure 8).

8. Attach SPEC Pak Receptacle to panel with eight, #6 screws (not included). Make sure the surface

of the panel contacting the sealing gasket is clean and dry to ensure an IP68 seal. Screws should be tightened

in an opposite, alternating manner, to provide even torque and sealing to the panel. (See Figure 9).

9. Position holder so

Receptacle

is facing up and APP Logo on Receptacle Shell is facing up.

Install contacts into Powerpole Housing(s). Position contacts as shown (See Figure 10). Push contact

and wire into Powerpole Housing so contact snaps into place. The contact will slip under the internal

barrier and snap over the end of the internal retaining spring. Repeat until all wires and contacts have

been firmly locked into their respective Powerpole Housings (See Figure 11a & 11b).

NOTE: To insert or remove a contact from a PP15/45 Powerpole Housing, use Anderson insertion /

extraction Tool P/N: 111038G20. Place one of the forward prongs of the tool between the contact and

spring. Using a rotary motion, continue rotation while pulling on the wire until the prong causes

disengagement of the contact from the retention spring (See Figure 12). Withdraw contact from the

rear of the Powerpole Housing. Reinstall contact into correct Powerpole Housing per Step 9 above.

To remove contact from Powerpole PP75 to PP180, use small, flat blade screwdriver to depress

contact retention spring below retention feature of contact (See Figure 12). Withdraw contact from

the rear of the Powerpole Housing. Reinstall contact into correct Powerpole Housing per Step 9 above.

10. Press Powerpole Holder into Receptacle Shell until 4 screw holes align. Holder and shell are

keyed so they will only go together one way. Insert four M5x25mm hex screws (supplied), using a

3mm hex bit, torque screws to 3-3.2 NM (25-26.5 in-lbs). The screw head should be recessed into

the countersink. CAUTION: Do not torque beyond 3.2 N-M (26.5 in-lbs) as this may cause damage

to the connector.

Figure 6a Figure 6b

Figure 7a

Figure 7b

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

1

2

3

4

5

6

7

8

Torque bolts to 26 - 30 in-Lbf (3 - 3.4N)