VIII. MAINTENANCE

15

There are several areas of the stove and chimney system

that will need periodic maintenance to ensure safe and

efficient operation.

1. ASH REMOVAL

When ashes get 3 to 4 inches deep in your firebox, wait

until the stove has cooled, then remove the grate at the

bottom of the heater into the ash pan below. Carefully

remove the pan. Ashes should be placed on a non-

combustible floor or on the ground, away from all

combustible materials pending final disposal. The ashes

should be retained in the closed container until all

cinders have thoroughly cooled.

NOTE: For the most efficient stove operation leave a

minimum of 2” ash in the firebox at all times. This will

help maintain a hot charcoal bed.

NOTE: DO NOT OVERFIRE THIS HEATER.

Attempts to achieve heat output rates that exceed heater

design specifications can result in permanent damage to

the heater and to the catalytic combustor.

2. CARE OF THE GLASS

The glass supplied with your stove is designed to

withstand extremely high temperatures. However, like

any glass product, IT CAN BE BROKEN! Take care not

to bump it with a log or a poker, and be sure the wood

is entirely inside the stove before attempting to close the

door.

Periodically opening the drafts and allowing the fire to

burn brightly will help reduce the soot buildup on the

glass. The glass may be cleaned with a NON-ABRASIVE

cleaner such as a spray glass cleaner or oven cleaner.

One of the simplest and most effective ways of cleaning

the glass is to dip a dampened rag in the ashes and scrub

the surface clean. The application of a non-stick cooking

spray to the inner surface of the glass will help keep it

clean.

6. ACHIEVING CATALYST LIGHT OFF WHEN

REFUELING

During the refueling and rekindling of a “charcoal

phase” fire, operate the stove at a medium or high firing

rate for about 10 minutes to ensure that the catalyst

reaches approximately 600 degrees F.

It is important to periodically monitor the operation of

the catalytic combustor to ensure that it is functioning

properly and to determine when it needs to be replaced.

A non-functioning combustor will result in a loss of

heating efficiency and an increase in creosote emissions.

3. CHIMNEY CARE

When wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled moisture

to form creosote. The creosote vapors condense in the

relatively cool chimney flue of a slow burning fire. As a

result, creosote residue accumulates on the flue lining.

The chimney connector and chimney should be

inspected at least twice yearly during the heating season

to determine if a creosote buildup has occurred.

If creosote has accumulated, it should be removed to

reduce the risk of a chimney fire.

NOTE: Insert model stoves should be removed from the

fireplace for cleaning. Slide the stove out and place it on

a piece of cardboard or drop cloths to protect the floor.

The fireplace and throat of the chimney CANNOT be

properly cleaned with the stove in place.

4. STOVE FINISH

All the stoves are finished with a specially formulated

high temperature paint. During the first few firings of

the stove, a slight odor of paint may be noticed. This is

normal during the curing process and the fumes are not

hazardous. If they should cause irritation, simply crack a

window or door for a few minutes to disperse the fumes.

NOTE: Although non-toxic, the fumes MAY set off a

smoke detector located near the stove.

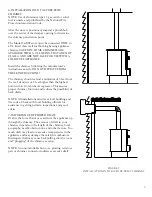

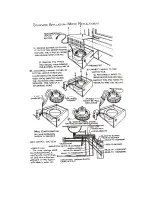

5. BLOWER CARE

The blower should be removed and cleaned every four

months. Unplug the blower before removing or servicing.

TO OIL THE BLOWER:

The blower should be oiled at least two times per season

with SAE-20. The oil ports (2) are located on the

opposite ends of the center hub on the top side of the

blower (see illustration - next page).

Summary of Contents for 36-BW

Page 18: ......