8

3. MOUNTING THE FREESTANDING KIT

Tool needed: Drill

A) Remove the wooden blocks from the bottom of the

stove. A drill may be used to remove the screws.

B) Position the pedestal on the bottom of the stove so that

the “turned in” flanges are against the bottom of the stove.

The front flange corners should be aligned with the widest

stove corners.

C) Attach the pedestal using the drill screws provided. Drill

into the holes after the pedestal is positioned correctly. The

screws will make their own holes in the stove bottom.

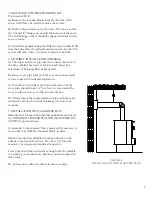

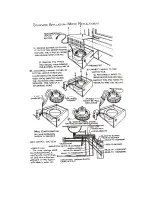

4. CHIMNEY INSTALLATION (GENERAL)

A) The single wall stove pipe used to connect the stove to

the flue, whether masonry or factory-built, must be a

minimum of 24-gauge blue or black steel.

B) Secure every pipe joint with three or more sheet metal

screws to prevent accidental separation.

C) If an elbow is installed, the horizontal section of the

stove pipe should slope 1/4” per foot, or run toward the

stove to allow creosote to drip into the firebox.

D) Always install the single wall stove pipe with the male

(crimped) end down to prevent leakage of creosote or

moisture.

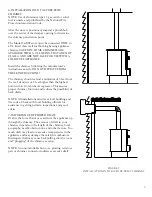

5. INSTALLATION INTO MASONRY FLUE

Masonry flue for use with solid fuel appliances must meet

the NATIONAL FIRE PROTECTION ASSOCIATION’S

CODE 211 specifications.

Connection to the masonry flue is made with a masonry or

terra-cotta type thimble cemented firmly in place.

Material around the thimble connection must provide

adequate protection from fire. Use either 24” of solid

masonry or an approved insulated connector.

Stove pipe should be inserted far enough into the thimble

to assure a good connection, but must not extend past the

flue lining.

Do not use more than one elbow in the stove pipe.

FIGURE 8

INSTALLATION INTO MASONRY FLUE

Summary of Contents for 36-BW

Page 18: ......