5

1.

2.

3.

4.

5.

6.

Turn ON the Appion TEZ8 momentarily with one of the inlet

ports open to remove any residual oil from the pump. Then

turn the machine OFF and unplug from power source.

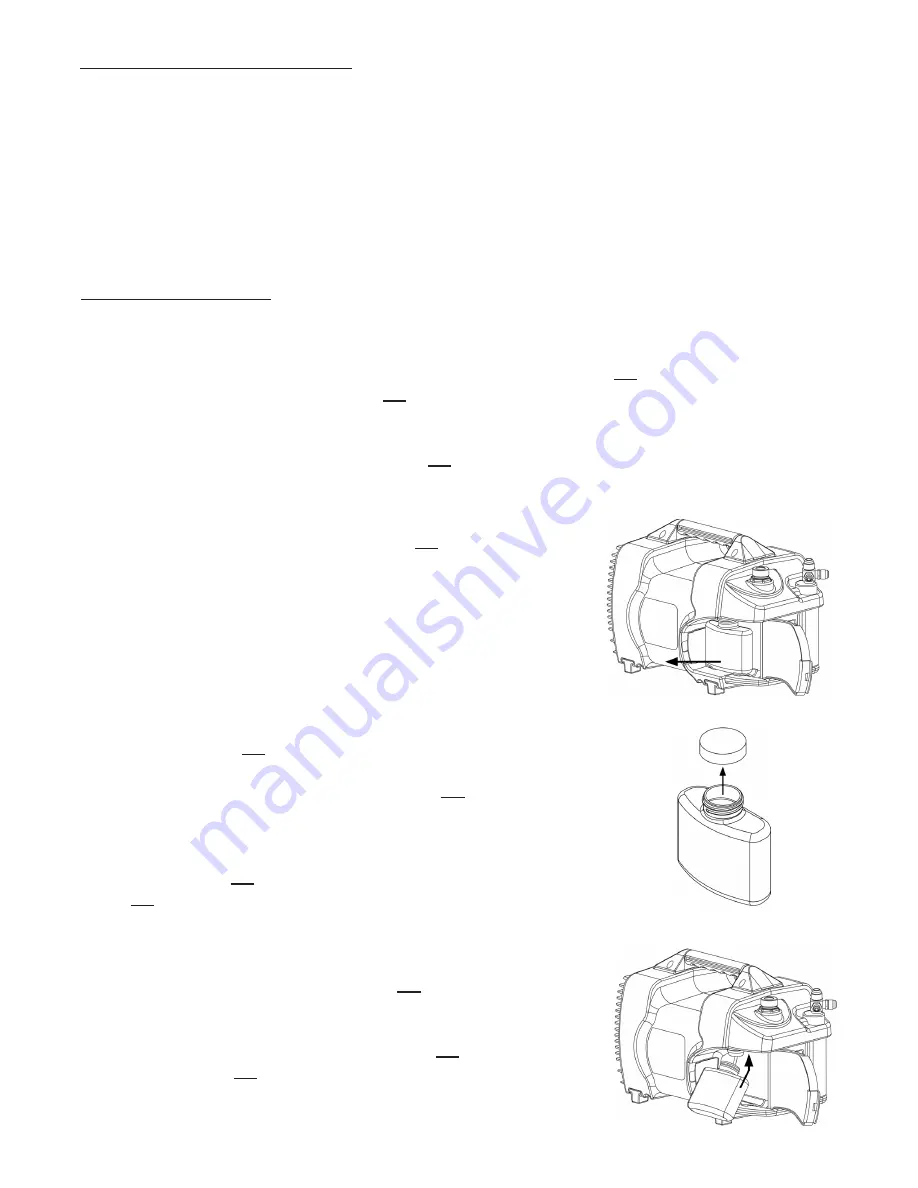

Open the large door on the left side of the machine to gain

access to the TEZ

OM oil cartridge.

While holding the lower part of the T

EZ

OM, pull the

cartridge out of the side of the vacuum pump. (Fig. 1)

Locate and remove the cap and protective seal from the

top of a new T

EZ

OM. The cap can be used to seal the old

TEZ

OM for easy disposal. (Fig. 2)

Note:

Dispose of the waste oil in accordance with your

local regulations.

Locate the flat side of the new T

EZ

OM and hold the

cartridge so that this is facing toward the machine.

Place the oil suction tube into the new T

EZOM and insert

the top of the T

EZ

OM first to make sure the oil suction tube

remains inside the cartridge. (Fig. 3)

Fig. 2

Changing the Oil

It is a good idea to always use clean fresh oil in your Appion TEZ8 vacuum pump. This not only

prolongs the life of the pump, but also helps you to achieve a rapid and deep ultimate vacuum.

Changing the oil in the Appion TEZ8 is as easy as installing a new T

EZ

OM oil cartridge following

the procedure below. Replacement T

EZ

OM Oil Cartridges can be purchased from your local

wholesaler.

Note:

Be sure to only use genuine Appion T

EZ

OM Oil Cartridges in your TEZ8 vacuum pump to

ensure optimal performance. The use of other vacuum oil may inhibit the ultimate vacuum depth

Fig. 3

Fig. 1

Positive Pressure Relief

If there is residual pressure in the system when the pump is attached to the system, the Debris

Monitor/Catch Tube will automatically disengage to relieve any positive pressure, preventing

damage to the TEZ8.

Once the pressure has been relieved, restart the TEZ8 and the suction will draw the tube back into

position, reseating itself on the double o-ring seal. If the catch tube does not reseat completely,

simply open the protective door and press the tube upwards into position.

that can be achieved.

Note:

The re-use or refilling of an Appion T

EZ

OM Oil Cartridge

may introduce contaminants and debris into the pump, resulting

in lost performance or damage to the TEZ8.