is dramatically affected by the diameter and length of the hoses being used to evacuate. Using a 3/8”

hose will allow FOUR times more throughput than a 1/4” hose. A 1/2” hose will allow 16 TIMES more

throughput than a 1/4”hose.

Even if you have to connect to a 1/4” access port, due the principals of flow in a vacuum as they relate to

pumping speeds, the use of a larger diameter hose will dramatically decrease your evacuation time.

Imagine that you are driving and encounter an accident on a busy highway. Traffic slows down while

everyone gathers into one lane in order to pass the accident. An entire highway full of cars being forced

into one lane for an entire trip is similar to how using small diameter hoses restricts throughput during

an evacuation.

Now, imagine that instead of being forced into one line for the entire trip, the accident is quickly passed

and the cars spread out into all of the lanes, returning traffic to full speed. This is how the principals of

flow in a vacuum operate: the greater the flow, the faster you go.

It is best if a system has multiple access ports at different points along the system. By attaching to as many

access ports as possible and evacuating from them simultaneously into the TEZ8, a technician can reach

the deepest vacuum throughout the entire system, in the least amount of time.

8

The Greater the Flow the Faster You Go

The rate of flow during the evacuation of a system is referred to as “throughput.” The throughput depends

on the resistance to flow and the pressure drop between the entrance and exit of a hose or channel. Large

Helpful Hints Continued

diameter hoses and clear evacuation paths will ensure

the most throughput and shortest evacuation times

.

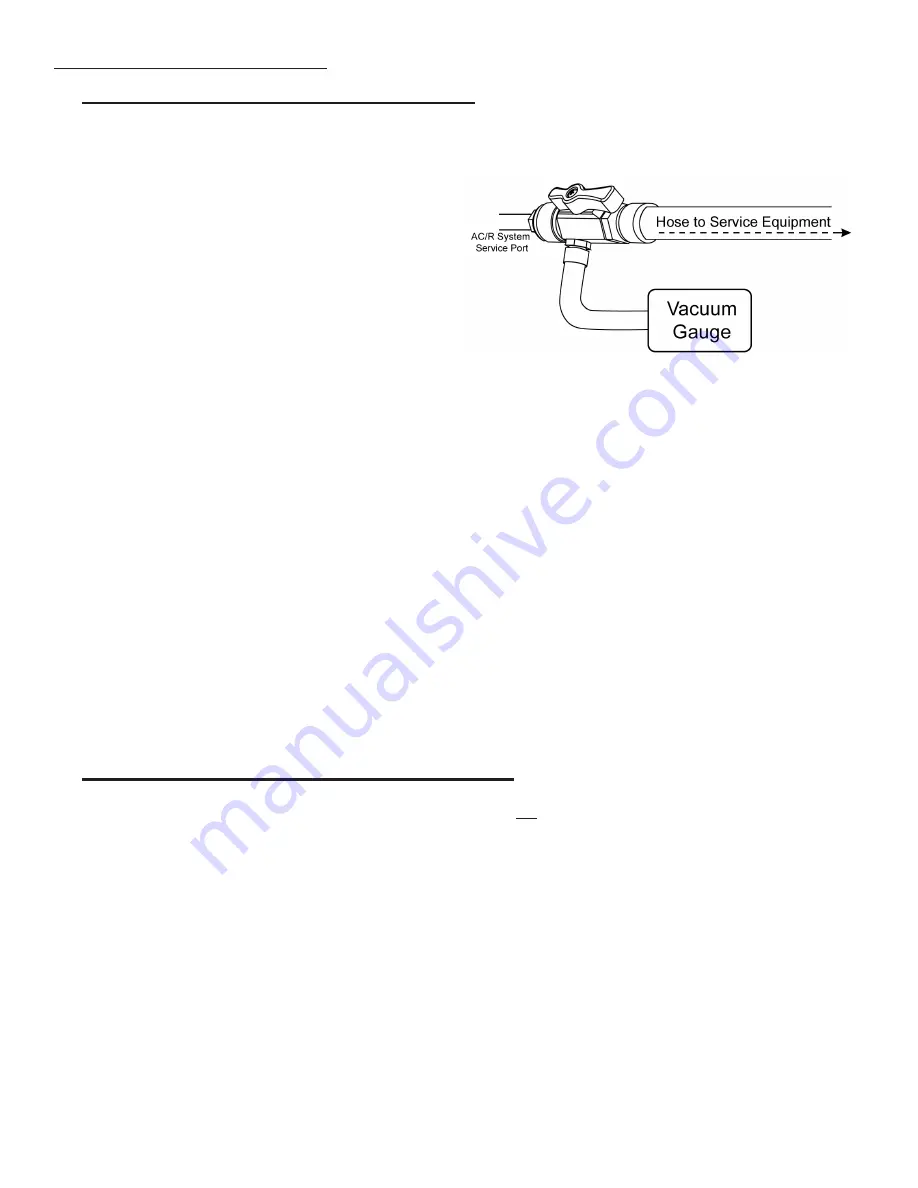

Remove restrictions such as core depressors in

hoses or Schaeder-type valve cores to ensure

maximum flow. It is recommended to use an Appion

Vacuum-Rated Valve Core Removal Tool

(see right)

in order to properly remove the access valve cores

and maintain a good seal for a deep vacuum.

When a system is in a vacuum the pumping speed

Excessive or Trapped Moisture in a System

It may be more difficult to pull a deep vacuum if the system oil has had significant exposure to atmospheric

air/moisture. Frequent oil changes due to contaminated T

EZ

OM oil can be an indication that there is

excessive moisture in a system.

Systems that use POE oil (approximately 100 TIMES more hydroscopic than mineral oil) can absorb a

considerable amount of moisture when opened to atmosphere. Purging the system with dry nitrogen prior to

evacuation can help clear the system of POE oil and moisture to reduce evacuation time considerably.

During the process of pulling a vacuum it is also possible that water or liquid may get trapped within the

system. This is not uncommon and usually happens where the system has low points or “traps” that can

catch moisture. While you are evacuating the system, look over the system for places on the outside of

the piping where condensation or frost are forming. At any locations where you find condensation or frost

on the outside of the piping you can be fairly certain that moisture is collecting inside.

Two possible methods for combating trapped liquid are applying heat to the outside of the piping with a

heat gun or by blowing nitrogen through the affected part of the system.

Example Valve Core Removal Tool Setup