NON METALLIC POWERTITE

®

PLUG SERIES

WIRING INSTRUCTIONS

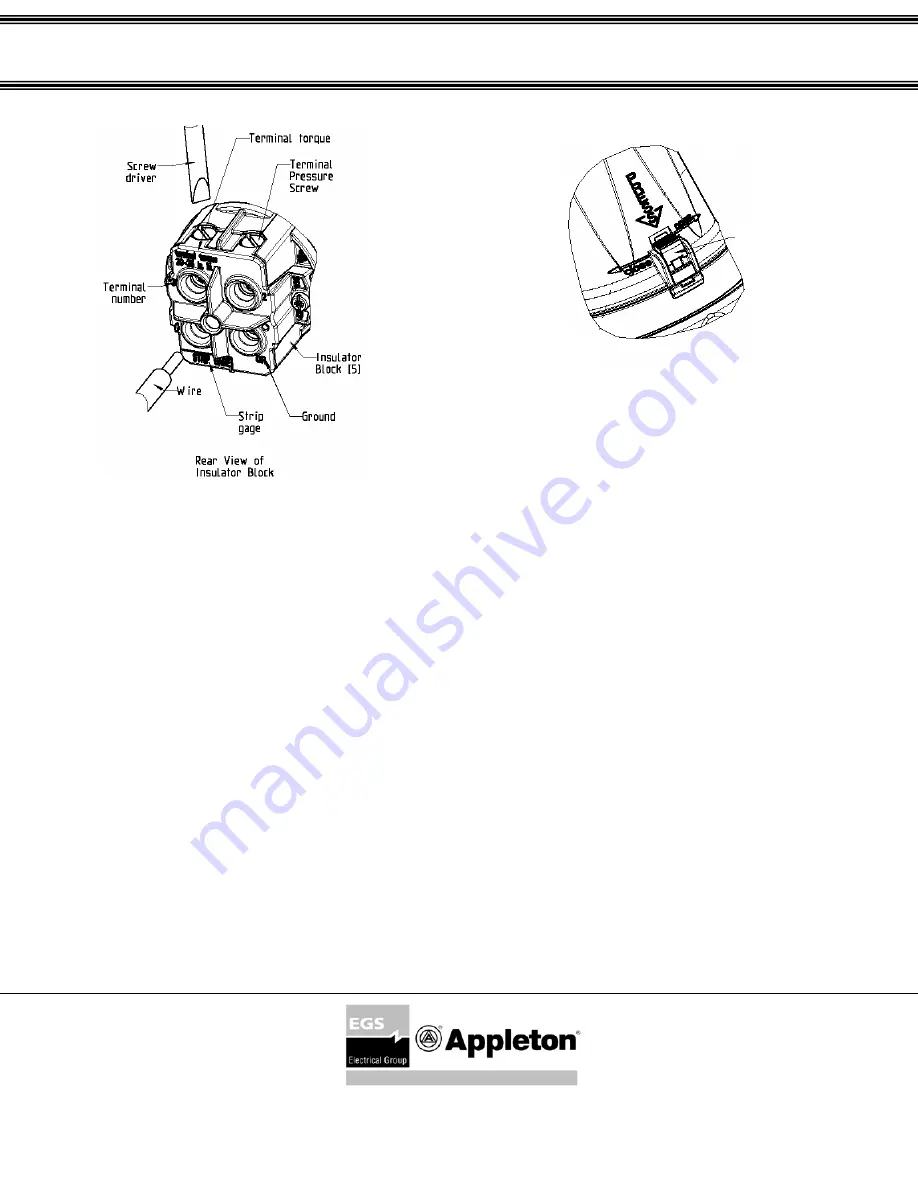

Figure 3

Figure 4

1. Choose the correct end of the cable for plug or connector so that conductor color coding corresponds to terminal location.

2. Disassemble plug as shown in Figure 1 by opening of the locking tab (10), unscrewing the rear housing (1) from the front housing

(2), loosening set screw (3) and unscrewing strain relief (4). It is not necessary to separate the insulator block (5) from the front

housing. Do not disassemble the insulator block.

3. Strip the cable jacket and individual conductors per Table A.

4. Slide strain relief (4) with adjustable cable clamps (6) and washer (7) over prepared cable.

5. Remove the "inner layers" from the multi-cut grommet (8) until it slips over the power cable. Remove one layer at a time, by

pushing through to solid side and tearing off. See Figure 3.

6. Slide cable through threaded opening of rear housing (1).

CAUTION

Apply the next steps with care. Otherwise the plug will not be tight and/or the cable grip will not be correct. Risk

of serious/fatal injuries due to electrocution could occur if steps are not completed properly.

7. Connect wires to proper terminals in insulator block. Back out terminal pressure screws if needed, but do not remove. Insert

conductors including all strands into contact terminals according to the established wiring pattern. Conductors must bottom in

contact terminal well. If stripped according to Table A the conductor insulation should extend below surface of insulator block.

Tighten terminal pressure screws to the torque value listed in Table A. The terminal torque can be found on the insulator block,

see Figure 3.

8. Thread rear housing (1) into front housing and align black locking tab (10) with receiving piece on front housing (2). Press tab (10)

as arrow directs to secure rear and front housing together.

9. Slide multi-cut grommet (8) and washer (7) into threaded entry of rear housing (1) Screw strain relief (4) into rear housing (1) and

torque per Table A. The torque value is located on the strain relief (4). Secure set screw in place so strain relief cannot turn.

10. Tighten cable clamp screws (11) around power cable to the torque in Table A. Alternate sides as needed to prevent binding.

Effective May 2014

Copyright © 2014 Printed in the U.S.A.

Specifications are subject to change.

Appleton Group

9377 West Higgins Rd.

Rosemont, IL 60018

847-268-6000

www.appletongroup.com

(10) Locking Tab