10

803809 Rev. 01

Room Freeze Protection

This feature is enabled when the unit is shipped from

the factory. The feature can be disabled by qualified

service personnel. If power is available to the unit, and

regardless of whether it is turned ON or OFF, the unit

will automatically supply heat to the room with the fan

running at low fan speed if the room temperature falls

to 50°F (10ºC). The heat will turn off when the room

temperature reaches 55°F (13ºC). For the feature to

work, the unit must be configured with an electric

heater. The feature is enabled whether the unit is

configured for keypad or remote thermostat. The

protection remains active when the unit is OFF, for

either keypad or remote thermostat application, as long

as the unit is plugged in, power is available, and a heat

source is configured in the unit and is working.

Compressor Short-Cycle Protection

If the electronic control shuts the compressor down for

any reason, a 3 minute time delay will elapse before the

compressor is allowed to re-start. This prevents

compressor overload during re-start due to unequal

system refrigerant pressures.

Indoor Coil Freeze Protection

Control of frost on the evaporator coil due to low

indoor loads, or cold outdoor ambient temperatures, is

provided.

Low Outdoor Temperature Lock-out

If the outdoor temperature is too low for proper

compressor operation, cooling operation will be

suspended until the outdoor temperature rises to an

acceptable point, depending on the application.

Indoor Temperature Limiting (Keypad Control

Only)

Using the keypad control and display, high and low

temperature limits can be established to prevent the

user from entering set point temperatures colder or

warmer than what the property manager or hotel

operator may desire. The temperature limit choices are

as follows:

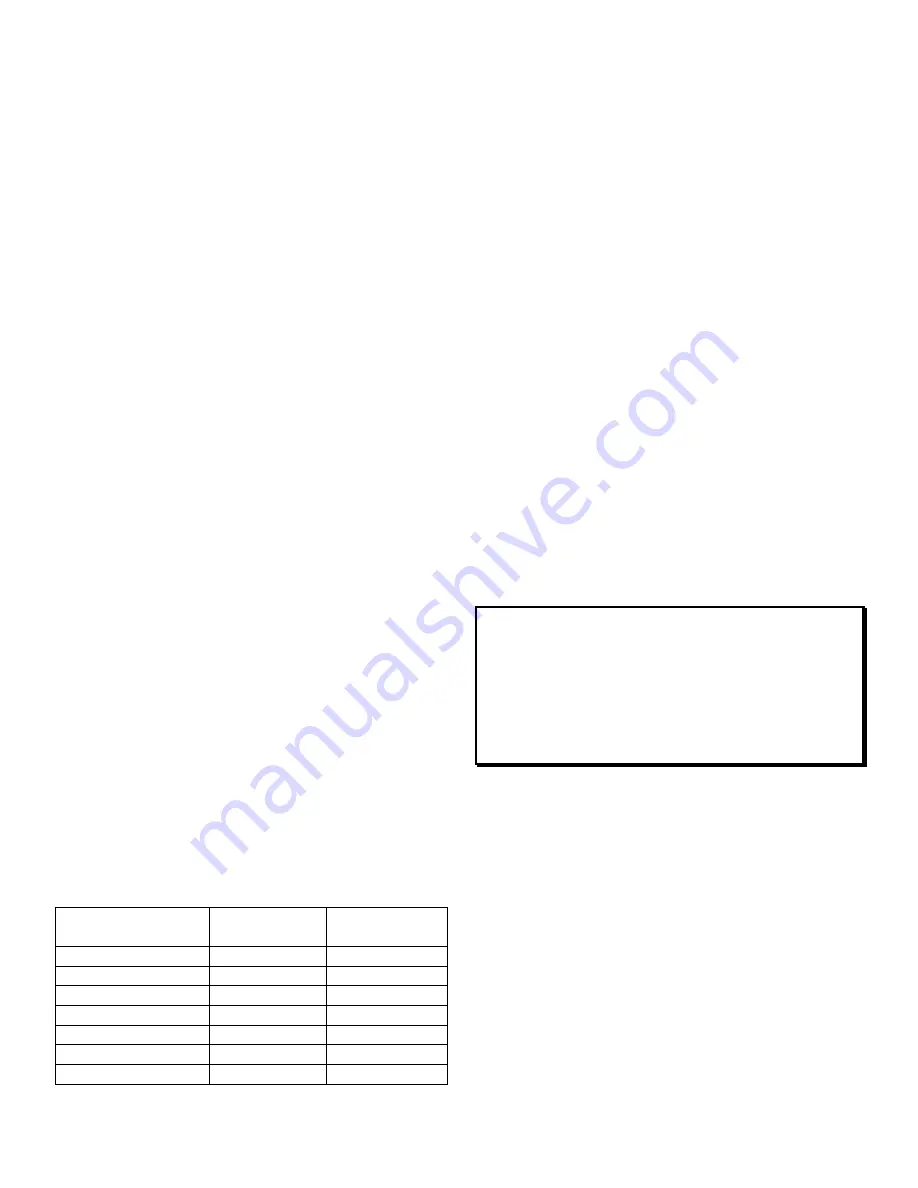

Configuration Code

Low Limit °F

(ºC)

High Limit °F

(ºC)

R1

63 (17)

86 (30)

R2

65 (18)

86 (30)

R3

65 (18)

90 (32)

R4

67 (19)

88 (31)

R5

67 (19)

92 (33)

R6

69 (20)

90 (32)

R7

69 (20)

72 (22)

The procedure to set the limits is as follows:

Depress the On/Off key, the °F/°C key, and the

Warmer key simultaneously for 5 seconds to enter the

limit setup mode. The Warmer and Cooler keys will

scroll through the R-values indicated in the above

table. Once the desired R-value has been obtained on

the display, press the On/Off key to accept the change,

and then press it again to effect the change and restore

the normal display.

Automatic Powered Damper

NFWC models are available with or without provision

for fresh air. However, if the units are configured to

bring in fresh air, they must have an automatic powered

fresh air damper that opens the fresh air door to bring

outdoor air into the room only when the indoor blower

is running. If the indoor fan shuts off, the damper

automatically closes and interrupts the heating coil’s

potential exposure to possible extremely cold air when

there is no blended air flow over the coil and/or no

flow of the heating medium inside the coil. The factory

default is fresh air with high speed fan operation only,

but it can be changed to open with low speed fan

operation only by having qualified service personnel

re-wire the unit as shown on the specific wiring

diagram affixed to the unit.

WARNING:

The speed conversion procedure involves

exposure to high voltage electrical circuits in the

control box in order to make the necessary change to

the damper action tied to motor speed, and must be

performed by qualified service personnel. Failure to do

so could result in property damage, personal injury or

death. Disconnect electric power to the unit before

servicing.

OPTIONAL AIR DUCT KIT:

The NFWC series has been designed and certified

for use with an optional external duct kit. It is

recommended that only the Applied Comfort

Products duct kit be installed on the unit.

The NFWC has been designed to use a 4.5” tall by

7.5” wide insulated (3/8” insulation) Duct Plenum

fastened to the top of the unit, which connects to a

maximum 48” long insulated (1/4” insulation)

Extension Duct of the same size, and uses an Air

Terminal Grille at the end of the Extension Duct

having an actual outlet area of

7.25”x 4.25” with