2

803809 Rev. 01

GENERAL INFORMATION

This model NFWC Applied Comfort PTAC is designed

and built for through-the-wall installation in either new

or existing buildings. The self contained compressor

and refrigerant system delivers the cooling, and the

tube-and-fin heat exchanger in the subbase provides the

heating by hot water or steam sources.

WARNING:

To avoid property damage, bodily injury

or death, ensure power is disconnected before any

service is attempted. Repairs should be made by

qualified service personnel only. The chassis must be

installed in accordance with the Authority Having

Jurisdiction, and all Local and National Codes,

including the National Electrical Code, and the

Canadian Electrical Code, as applicable.

FOR EFFICIENT OPERATION

Air Filter

The washable air filter is not shipped with the chassis –

it is shipped installed in the heating subbase. Operating

the unit without an air filter will void the warranty.

Keep air filter clean. The air filter can be removed and

cleaned with soap and water. Inspect and clean the

filter a least once a month or more often as conditions

dictate. Replace as necessary. A dirty, clogged filter

reduces the efficiency of the system. It can also cause

erratic performance of controls and can result in

damage to the motor and compressor.

ATTENTION:

An improperly maintained air filter or

not using an air filter at all will void the warranty. The

unit must not be used for temporary heating or cooling

during the building’s construction stage.

To access the air filter, first remove the grille cover

from the heating subbase by rotating the two ¼ turn

finger and thumb fasteners until the grille cover

releases. The unit front panel need not be removed. The

air filter is located directly below the heat exchange

coil and slides out freely. Always replace the grille

cover after re-inserting the filter.

CAUTION:

Risk of bodily injury. Be aware that the

heating coil, valve, and piping may be extremely hot

and can potentially cause burns even if the unit is not in

operation, due to residual heat. Always replace the

grille cover after re-inserting the filter before operating

the unit.

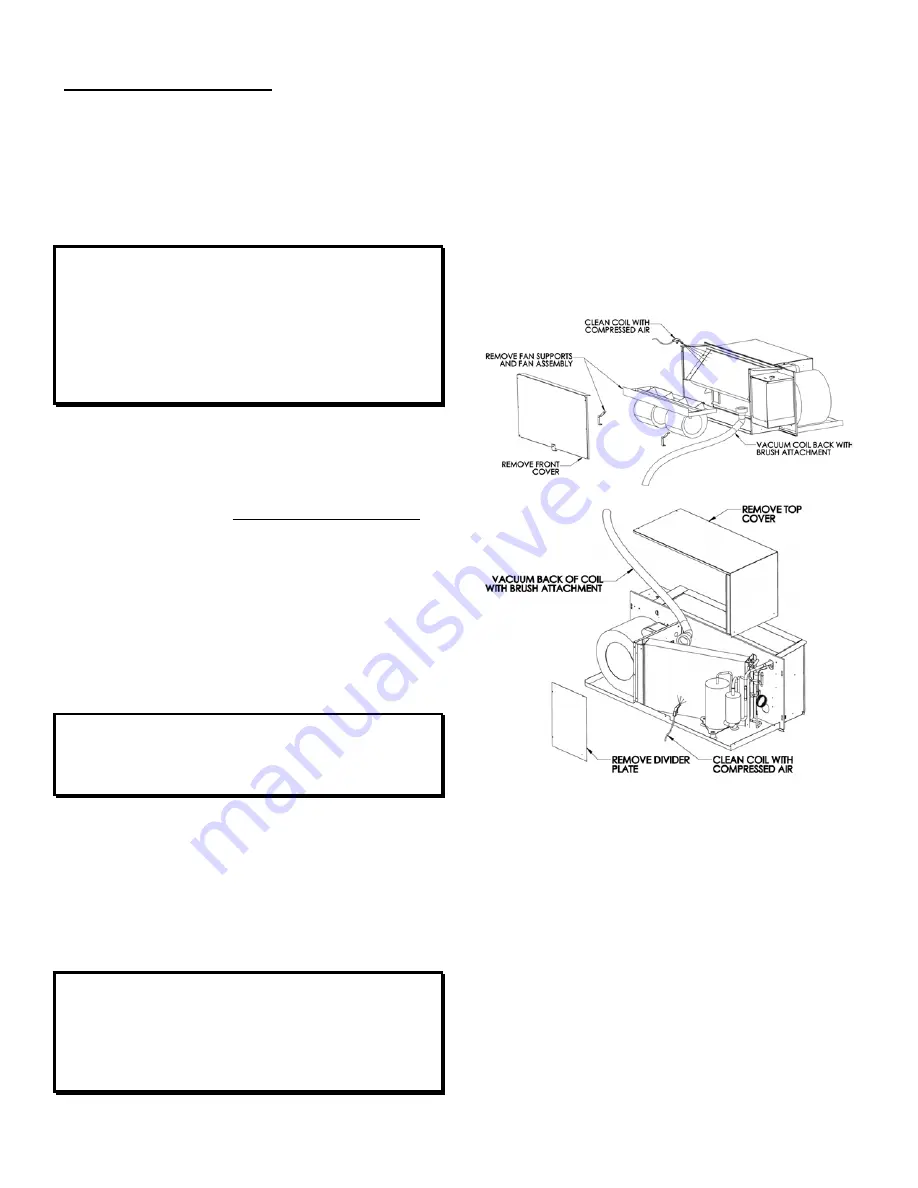

Clean Coils

As part of regular servicing, clean the condenser coil,

and evaporator coil at least annually, or more often as

dictated by the severity of the particulates and

pollutants circulating in the outdoor and indoor

operating environments. One suggested method is as

follows:

Unimpeded Outdoor Airflow

Do not block off the outside air flow to the unit. The

condenser air inlet and outlet must be free of

obstructions and of any external influence that would

cause the hot discharged condenser air to be re-

circulated back into the outdoor blower intake. Outdoor

air is drawn into the outdoor blower on the left side of

the rear grill (viewing grille). Hot condenser air is

forced sideways out of the right hand portion of the

rear grill, minimizing air re-circulation back into the

blower intake. Paper, leaves, dirt, or other material

blocking airflow, or fouling the condenser coil surface,

can impair efficiency and cause serious damage to the

compressor.