Installation and Service Manual – Metered Carbon Filter

Page 26

Copyright © 2012 Applied Membranes, Inc. All Rights Reserved.

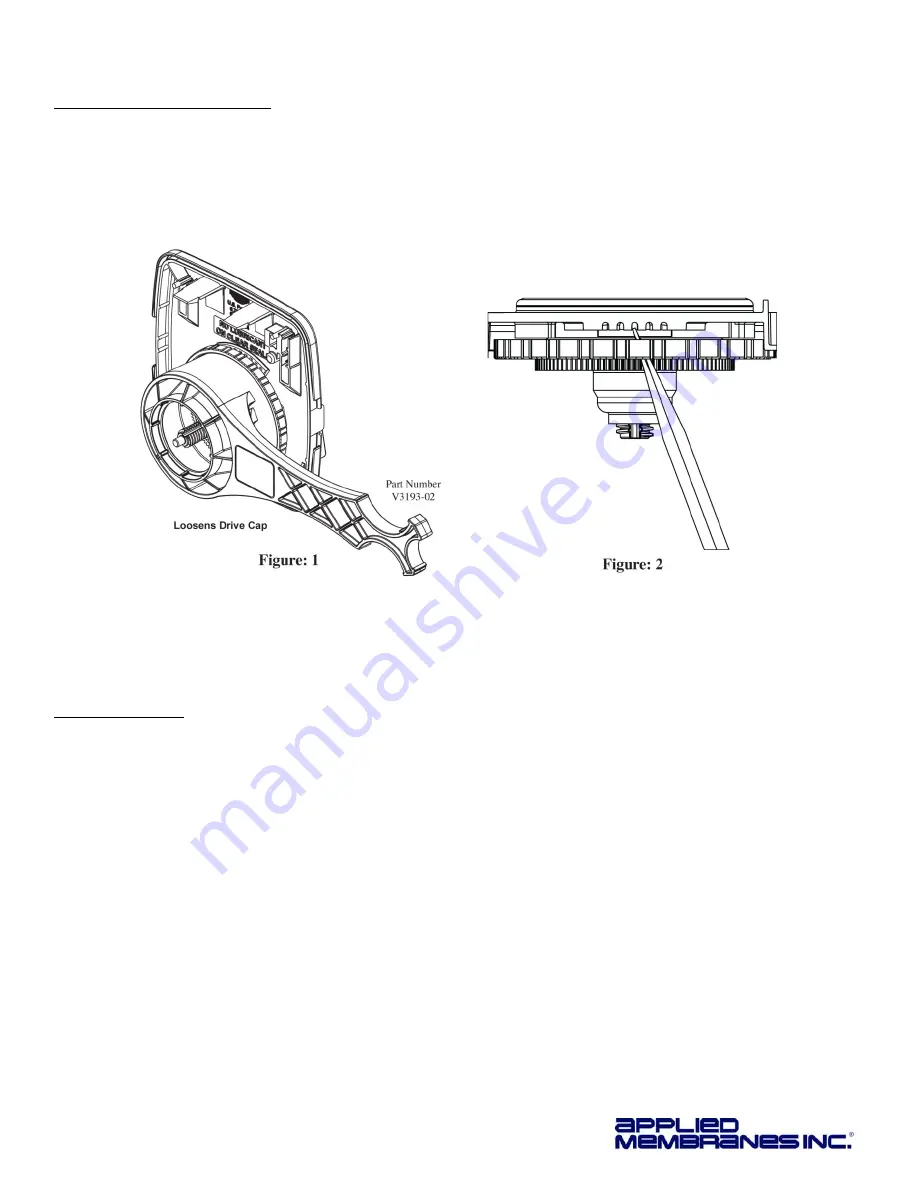

Drive Cap Assembly

Disassembly:

Turn off supply water and relieve system pressure. The drive assembly must be removed to access the

drive cap assembly. The drive cap assembly must be removed to access the piston(s). The drive cap assembly is

threaded into the control valve body and seals with an o-ring. To remove the drive cap assembly use the special plastic

wrench (V3193-02 Figure 1) or insert a ¼” to ½” flat bladed screwdriver into one of the slots around the top 2” of the drive

cap assembly so it engages the notches molded into the drive back plate around the top 2” of the piston cavity. See

Figure 2. The notches are visible through the holes. Lever the screwdriver so the drive cap assembly turns counter

clockwise. Once loosened unscrew the drive cap assembly by hand and pull straight out.

Inspection:

The drive cap assembly contains the drive cap, the main drive gear, drive cap spline, piston rod and various

other parts that should not be dissembled in the field. Visually inspect the drive cap for damage and free operation of the

gear and threaded rod. The only replaceable part on the drive cap assembly is the o-ring.

Main Piston

Disassembly and Inspection:

Attached to the drive cap assembly is the main downflow piston. To remove, fully extend

the piston rod and then unsnap the main piston from its latch by pressing on the side with the number. Chemically clean

the piston in dilute sodium bisulfite or vinegar, or replace it. The main piston is Teflon coated. If the teflon coating is

abraded, replace the main piston.

Reassembly:

Reattach the main piston to the drive cap assembly. Reinsert the drive cap assembly and piston into the

spacer stack assembly and hand tighten the drive cap assembly. Continue to tighten the drive cap assembly until the

backside of the drive cap bottoms out and is flush with the casting or the black o-ring on the spacer stack assembly is no

longer visible through the drain port. Excessive force can break the notches molded into the drive back plate. Make

certain that the main drive gear still turns freely. The exact position of the piston is not important as long as the main drive

gear turns freely.

Reattach the drive assembly to the control valve and connect all plugs. After completing any valve maintenance, press

and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (4 pin, black cable) and plug back in. This

resets the electronics and establishes the service piston position. The display should flash all wording, then flash the

software version and then reset the valve to the service position.