Installation and Service Manual – Metered Carbon Filter

Page 6

Copyright © 2012 Applied Membranes, Inc. All Rights Reserved.

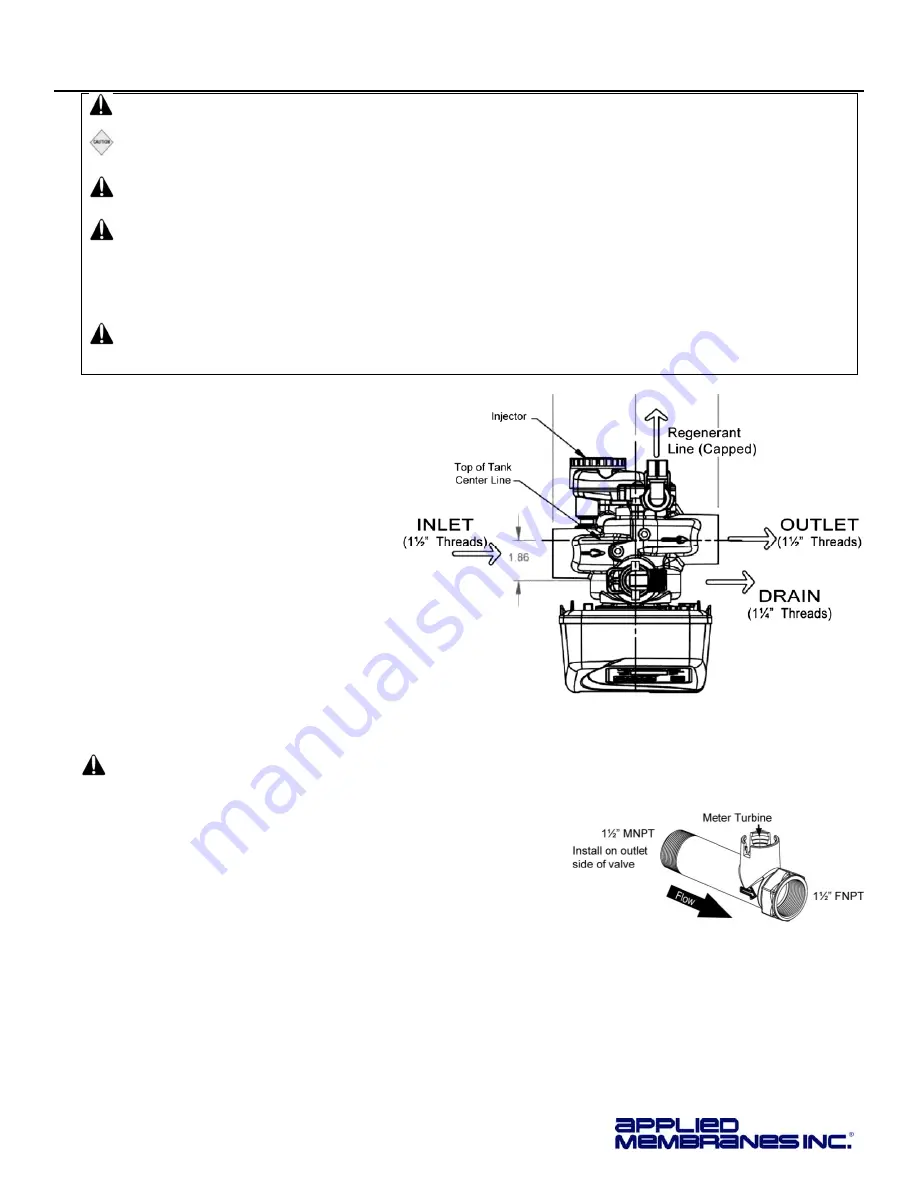

Plumbing

Note:

All plumbing is to be done in accordance with state and local codes.

Caution:

Before placing wall anchors to support piping ensure that no electrical conduit or wiring is located

behind the intended mounting location.

Note:

The control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments

but are not designed to support the weight of a system or the plumbing.

Note:

Connect to a supply line downstream of outdoor spigots. Install an inlet shutoff valve and plumb them

to the unit’s inlet. Installation of a bypass valve is recommended. If using plastic fittings, ground the water

conditioner per local electrical codes. If a water meter is used, install the water meter on the outlet side of the

control valve. The turbine assembly may be oriented in any direction, but is usually oriented pointing up to reduce

drainage out of the pipe during service.

Note:

Do not use pipe dope or other sealant on threads. Use teflon tape on threaded inlet, outlet and drain

fittings.

1. Install connecting piping between raw

water source and input pipe on control

valve.

2. Install drain line from control valve to

a free flowing drain.

A 1.25” Male NPT × 1.5” Female NPT SS

drain flow control is installed on the valve.

Solder joints near the drain must be done

prior to connecting the drain line flow

control fitting. Leave at least 6”

(152.4mm) between the drain line flow

control itting and the solder joints to

prevent heat from damaging the flow

control. Avoid elevating the drain line

above the control valve where possible.

Discharge the drain line through an air

gap to a receptacle in accordance with

local plumbing codes.

Important:

Never insert a drain line directly into a drain, sewer line or trap. Always allow an air gap between

the drain line and the receptacle to prevent back siphonage.

3. Install the water meter on the outlet side of the control valve

.

The meter may be threaded directly into the valve or may be

plumbed separately downstream of the unit*. Ensure the arrow on

the meter body is going the same direction as the water flow. The

turbine assembly may be oriented in any direction, but is usually

oriented pointing up to reduce drainage out of the pipe during

service. Meter can be installed horizontally or vertically.

*A longer cable (Part #V3221) is required for distances longer than 3” from

the valve body.