20

SV200 DC Hardware Manual

920-0126A

4/14/2017

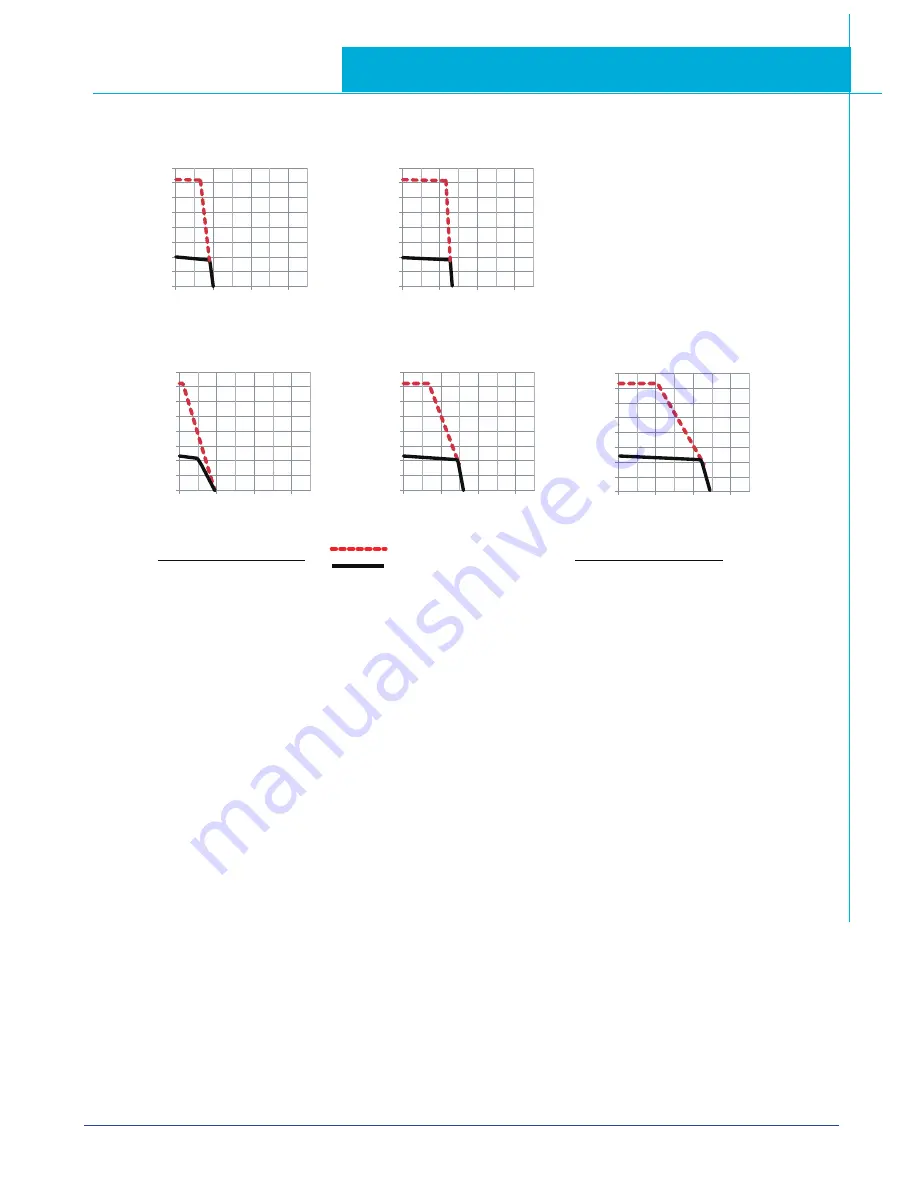

60mm Torque curves--400W

Max. Intermi

�

ent Torque

Max. Con

�

nuous Torque

To

rq

ue

(N

m

)

Speed (rpm)

To

rq

ue

(N

m

)

Speed (rpm)

To

rq

ue

(N

m

)

Speed (rpm)

0

0.5

1

1.5

2

2.5

3

3.5

4

0

2,000 4,000 6,000

DC Bus--24VDC

J0400-404-5-000(400 Watts) -10Amps

0

0.5

1

1.5

2

2.5

3

3.5

4

0

2,000 4,000 6,000

DC Bus--48VDC

J0400-404-5-000(400 Watts) -10Amps

0

0.5

1

1.5

2

2.5

3

3.5

4

0

2,000 4,000 6,000

DC Bus--60VDC

J0400-404-5-000(400 Watts) -10Amps

To

rq

ue

(N

m

)

Speed (rpm)

To

rq

ue

(N

m

)

Speed (rpm)

0

0.5

1

1.5

2

2.5

3

3.5

4

0

2,000 4,000 6,000

DC Bus--48VDC

J0400-305-4-000(400 Watts) -6.9Amps

0

0.5

1

1.5

2

2.5

3

3.5

4

0

2,000 4,000 6,000

DC Bus--60VDC

J0400-305-4-000(400 Watts) -6.9Amps

0

4.4

22.1

25.6

30.9

12.3

17.7

8.9

35.4

0

4.4

22.1

(In-lb

)

Torque

25.6

30.9

12.3

17.7

8.9

35.4

0

4.4

22.1

(In-lb

)

Torque

25.6

30.9

12.3

17.7

8.9

35.4

0

4.4

22.1

(In-lb

)

Torque

25.6

30.9

12.3

17.7

8.9

35.4

0

4.4

22.1

(In-lb

)

Torque

25.6

30.9

12.3

17.7

8.9

35.4

(In-lb

)

Torque