TROUBLESHOOTING

DISPLAY IS BLANK

If Power LED is not illuminated at the equipment

control module check the following:

• Check circuit breaker and reset if necessary .

• Make sure power switch at heating & cooling

system is on .

• Make sure furnace door is closed securely .

HEATING SYSTEM DOES NOT RESPOND

(“HEATING” APPEARS ON SCREEN)

• Check for 24VAC at the equipment on the secondary

side of the transformer between power and

common . If voltage is not present, check the heating

equipment to find the cause of the problem .

• Check for 24VAC between the heat terminal (W)

and the transformer common . If 24VAC is present,

the thermostat is functional . Check the heating

equipment to find the cause of the problem .

• Check for loose or broken wires between the

thermostat and the heating equipment .

COOLING SYSTEM DOES NOT RESPOND

(“COOLING” APPEARS ON SCREEN)

• Check for 24VAC at the equipment on the secondary

side of the transformer between power and

common . If voltage is not present, check the cooling

equipment to find the cause of the problem

• Check for 24VAC between the cooling terminal (Y)

and the transformer common . If 24VAC is present,

the thermostat is functional . Check the cooling

system to find the cause of the problem .

• Check for loose or broken wires between the

thermostat and the cooling equipment .

FAN DOES NOT TURN ON IN A CALL FOR HEAT

• Check Installer Setting

Fan Control In Heating /

Heat Pump Auxiliary Type

, to make sure the fan

control is properly set to match the type of system .

HEAT PUMP ISSUES COOL AIR IN HEAT MODE,

OR WARM AIR IN COOL MODE

• Check wiring at the terminal block to confirm the

reversing valve is connected to the proper terminal .

O is active in cooling and B is active in heating .

HEAT/COOL BOTH ON AT SAME TIME

• Check Installer Setting

Equipment Type

, to make

sure it is set to match the installed heating/cooling

equipment .

• Check to make sure heating and cooling wires are

not shorted together .

HEATING EQUIPMENT IS RUNNING IN

COOL MODE

• Check Installer Setting

Equipment Type

, to make

sure it is set to match the installed heating/cooling

equipment .

“HEATING” IS NOT DISPLAYED

• Check Installer Setting

Control Setup

is set

correctly .

• Change the System Mode to Heat, and set

the temperature level above the current room

temperature .

“COOLING” IS NOT DISPLAYED

• Check Installer Setting

Control Setup

is set

correctly .

• Change the System Mode to Cool, and set

the temperature level below the current room

temperature .

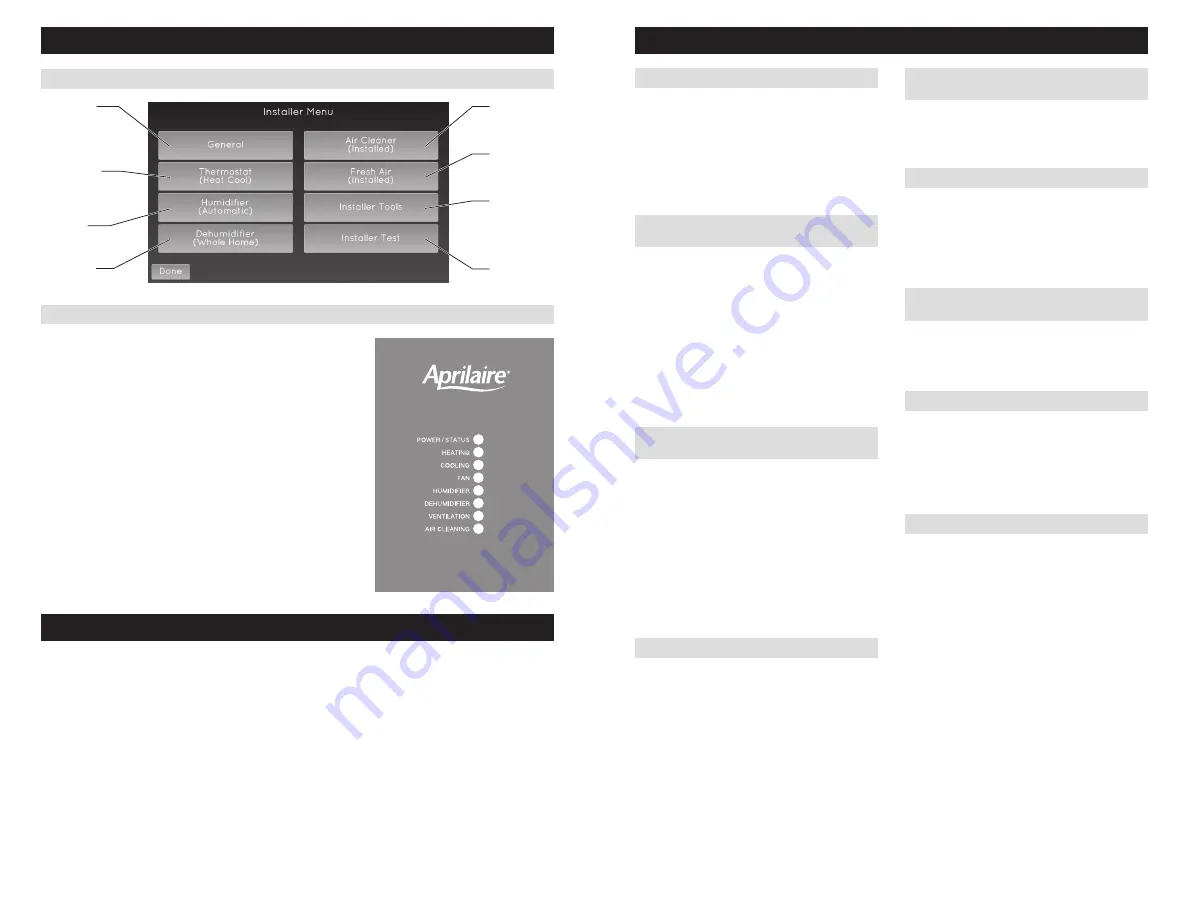

INSTALLER MENU

USB SETTINGS

FILE IMPORT, ETC

THERMOSTAT &

HVAC SYSTEM

CONFIGURATION

HUMIDIFIER

CONFIGURATION

DEHUMIDIFIER

CONFIGURATION

EQUIPMENT

OUTPUT TESTS

IMPORT/EXPORT

USB INSTALLER

SETTINGS FILES,

FACTORY RESET

VENTILATION

CONFIGURATION

AIR CLEANER

CONFIGURATION

QUICK REFERENCE TO CONTROLS & DISPLAY

POWER/STATUS

– On solid during normal operation . Flashes

when connection to the thermostat is lost and at power-up while

the thermostat connection is being established .

HEATING

– On when heating outputs are active .

COOLING

– On when cooling outputs are active .

FAN

– On when fan output is active .

HUMIDIFIER

– On when humidifier output is active .

DEHUMIDIFIER

– On when dehumidifier output is active .

VENTILATION

– On when ventilation output is active .

AIR CLEANING

– On when air cleaner output is active .

EQUIPMENT CONTROL MODULE LEDs

THERMOSTAT FEATURES

• Remote access and control over Wi-Fi .

• Indoor air quality control .

– Humidification automatic or manual control .

– Dehumidification .

– Event-Based

™

air cleaning .

– Ventilation with temperature and humidity limits .

• Temperature control .

• Heat Blast

®

raises the room temperature 3°F to 5°F .

• One touch Away .

• Support for optional wireless outdoor temperature

sensor .

• Large touch screen with adjustable backlight .

• 7 day programmability .

• Displays room temperature, room humidity,

temperature setting, and optional outdoor temperature .

• Air filter, humidifier, dehumidifier, and HVAC service

reminders .

• Programmable fan control with fan circulation mode .

• Easy to use temperature control can override program

schedule at any time .

• Progressive recovery ensures proper temperature at

the start of a program event .

• Built in compressor protection prevents damage to

your equipment .

• System test mode .

English

19

18

English