CHECKING WEAR LIMITS

Chart references

Component

Wear limit

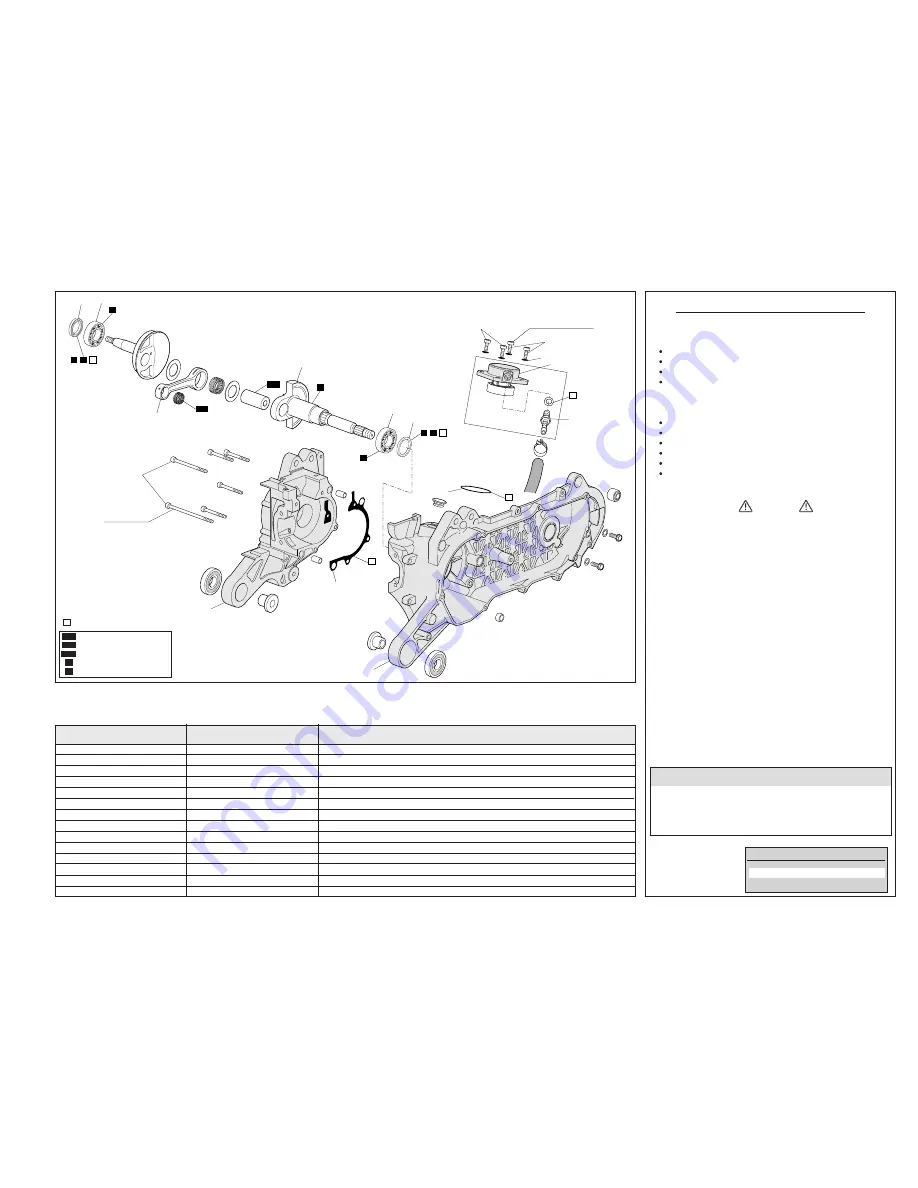

DISASSEMBLY SEQUENCE

4-5 Nm (0,4-0,5 kgm)

10 Nm (1 kgm)

1

3

5

2

1

4

6

N

N

N

12

14

10

11

13

G

G

G

G

N

L

G

N

L

OM

OM

15

8

7

9

AIR COMPRESSOR

Remove the 4 screws (1) without losing the washers (2).

Remove the compressor (3) from the guard.

Remove the OR (4).

Unscrew the compressor connector (5).

COVER AND CRANKCASE

Remove the six cover screws (6).

Separate the RH half (7) from the LH half (8) of the cover.

Remove the gasket (9).

Remove the crankcase (10) from the RH half.

Remove the RH oil guard (11) and LH oil guard (12).

Remove the RH (13) and LH (14) bearing.

WARNING

N.B.: Grease the RH (13) and LH (14) crankshaft main

bearings.

REASSEMBLY

Reverse the order of disassembly instructions, making sure

tightening torques are correct, and all components requiring

grease are greased or, if necessary, replaced with components

specified in the table.

10

Crankcase

10

Crankcase

10

Crankcase

15

Connecting rod

Standard width: 37.95 – 38.10 mm

Off-line tolerance 0.03 mm (measured at two opposite points)

Connecting rod head side play: 0.85 mm (original: 0.75 mm)

Max diameter connecting rod foot: 16.04 mm (original: 16.003 – 16.011 mm)

RELEASE 00 2002 - 09 AIR INJECTION

COVER + CRANKCASE

Chap.6 TABLE

05

: Engine oil

: Gearbox oil

: Molybdenum bisulphuroil

: Grease

: Loctite

OM

O.C.

OBM

G

L

: New item

N