ENGINE

3 - 35

ENGINES C361M / C364M

3.6.3.

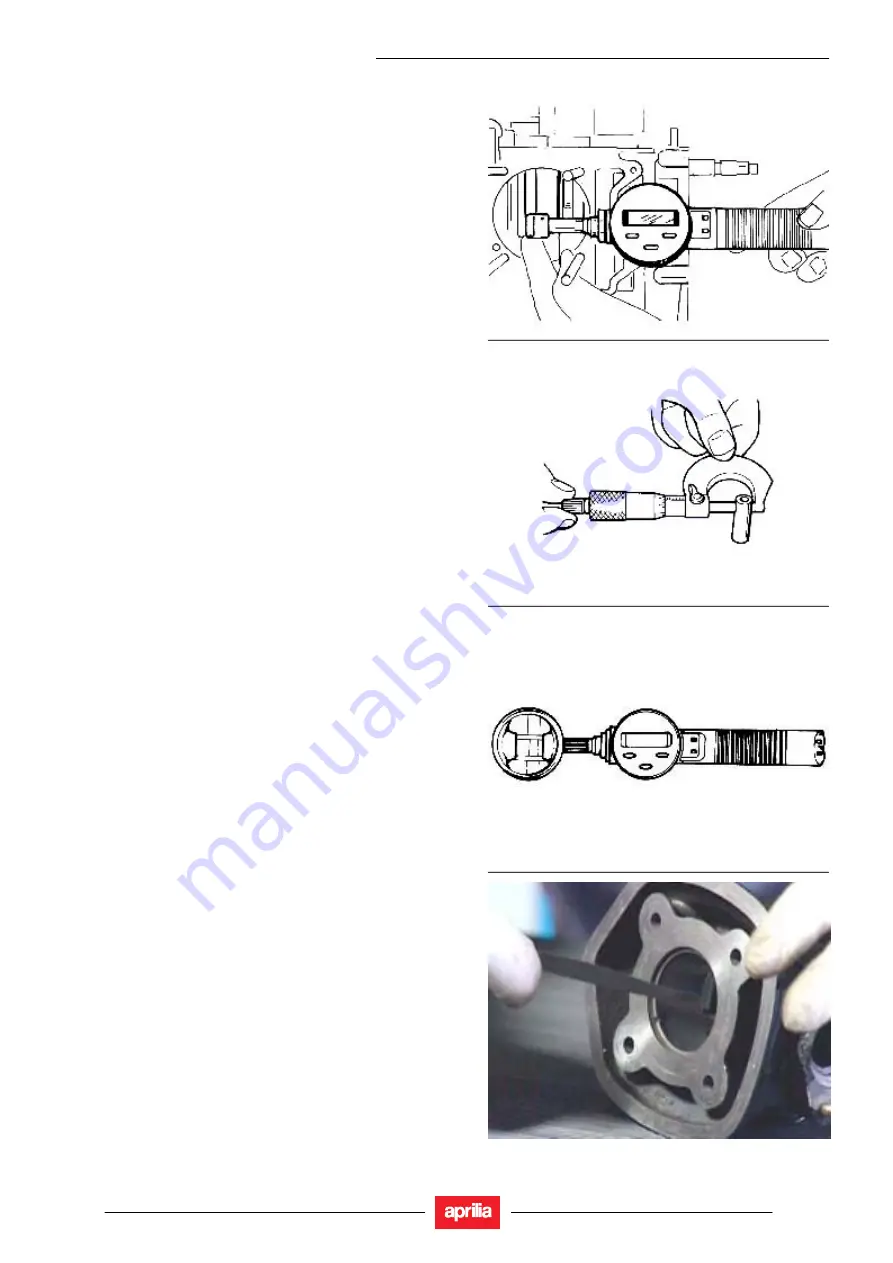

CHECKING THE CYLINDER AND PISTON

•

Make sure the roller lane of the small end of the con

rod is not abnormally worn.

•

Measure the inside diameter of the small end with a

bore gauge.

•

Standard diameter 17 ± 0.001 mm

•

Use a micrometer to measure the outside diameter of

the pin.

•

Standard diameter 12 + 0.005 - 0.001 mm.

•

Measure the diameter of the contacts on the piston

with a bore gauge.

•

Standard diameter 12 + 0.007 - 0.012 mm.

•

Calculate the pin-piston coupling play

•

Standard play 0.002 - 0.011 mm

•

Check that the surface of the cylinder is not scored and

check its wear with a centesimal comparator.

•

Zero the comparator on a ring gauge and use it to

measure the inside diameter of the cylinder.

•

Use the piston to fit the circlip at right angles to the axis

of the cylinder.

•

Check the clearance at the end of the circlip with a

feeler gauge.

Summary of Contents for C216M

Page 1: ...www serviceaprilia com workshopmanual Engines C361M C364M C216M 1234 4 00 2004 10 8140822 UK ...

Page 8: ...GENERAL INFORMATION 1 1 ENGINES C361M C364M GENERAL INFORMATION 1 ...

Page 17: ...TECHNICAL INFORMATION 2 1 ENGINES C361M C364M TECHNICAL INFORMATION 2 ...

Page 23: ...ENGINE 3 1 ENGINES C361M C364M ENGINE 3 ...

Page 81: ...ENGINE 3 59 ENGINES C361M C364M Lubricate the bearings and big end ...

Page 93: ...ENGINE 3 71 ENGINE C361M Remove the fins support ...

Page 101: ...UPDATES ENGINE C364M 4 1 ENGINES C364M UPDATES ENGINE C364M 4 ...

Page 118: ...UPDATES ENGINE C364M 4 18 ENGINE C364M ...

Page 128: ...UPDATES ENGINE C216M 5 1 ENGINE C216M UPDATES ENGINE C216M 5 ...

Page 134: ...UPDATES ENGINE C216M 5 7 ENGINE C216M Slide the oil hose to remove the cooling case ...