-

12

-

English

AP031

R

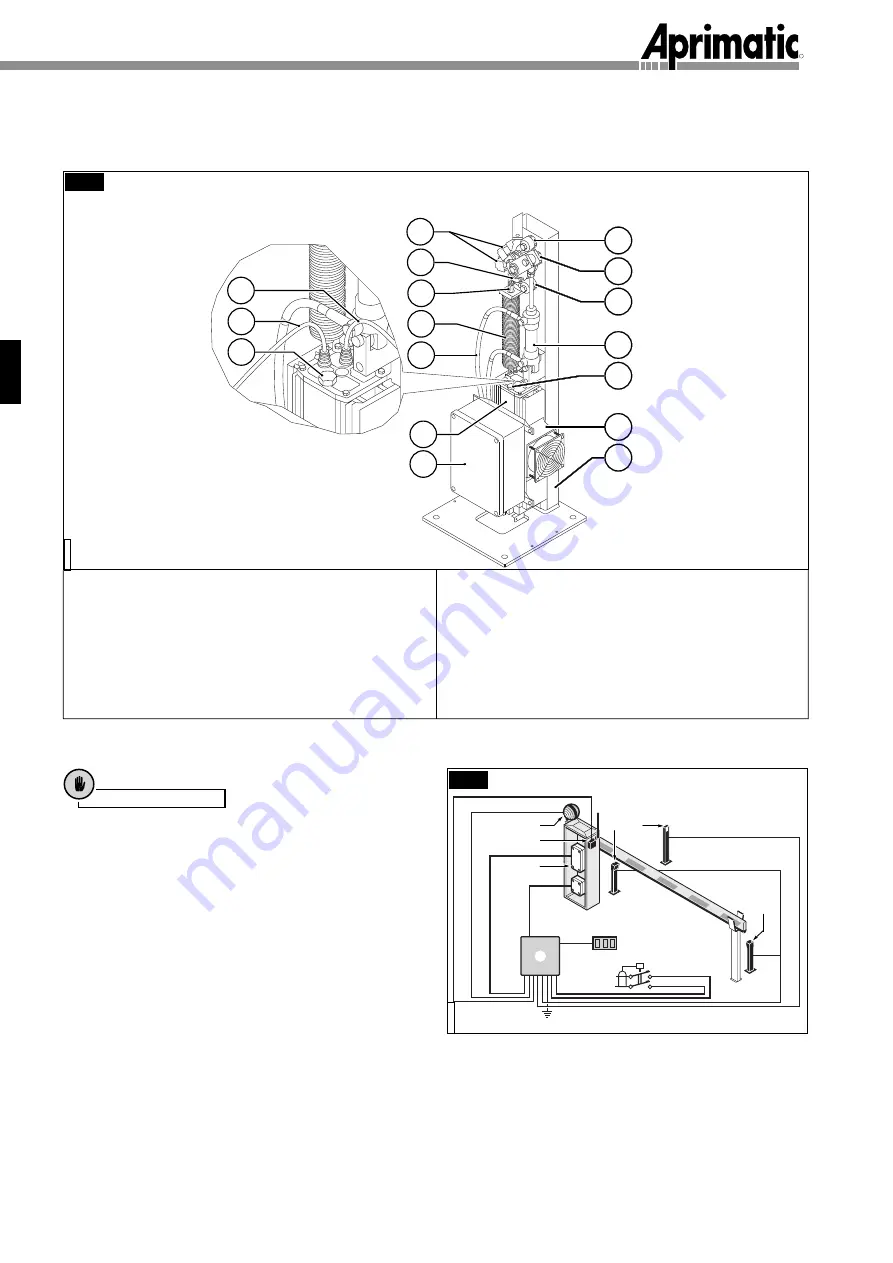

4.1 BARRIER INSTALLATION

The two barriers only differ for some mechanical parts contained inside the box (

fig. 7

).

Such differences do not modify the installation sequence or the adjustment of the barriers.

Caution

The electrical connection of the operator to the

electronic control unit must be done only by skilled

personnel according to the instructions provided

with the control unit.

The electronic control unit can be fi xed inside the box

using the special holes.

For the connection of electrical control and safety

appliances, follow the wiring diagram.

If, during opening or closure, the electric motor of the

hydraulic control unit runs, but the barrier does not

move, proceed as follows:

– cut the power off;

– check the electrical connection of the entire circuit;

– reverse the poles of the electric motor if necessary.

9

10

13

4

6

2

1

8

5

8

3

7

12

11

Motorway barrier 163/164

15

14

7

AP007007

Fig.7

4.2 ELECTRICAL CONNECTION

1

Control unit

2

Hydraulic control unit

3

Hydraulic piston for lever motion

4

Compensation spring

5

Beam control lever

6

Hydraulic piston supply hoses

7

Oil fi ller

8

Mechanical stop pad

9

Stroke end control cam

10

Limit switch

11

Supporting frame

12

Cooling fan and baffl e plate

13

Compensation spring chain

14

Oil cooling fan thermostat wire

15

Motor power cable

2x1,50(230V) 3x1,5(24V)

4Fx1,5

230 V

50 Hz

2x1,50

6A

Ie=30 mA

8

7

3x1

2x1

2x1

4x1

1

2

4

3

6

5

AP025048

Fig.12

Legend:

1 -

Hydraulic control unit motor power supply

2 -

24V-230V fl ashlight

3 -

Receiving radio control

4 -

Key-contact

5 -

Emitting photocell

6 -

Receiving photocell

7 -

Internal control panel

8 -

Electronic control unit

Barrier installation