-

17

-

R

AP031

English

Barrier maintenance / Troubleshooting

6.1 BARRIER MAINTENANCE

- Regularly check the integrity of hydraulic hoses, metal rope and electrical wires inside the barrier body.

- Check the effi ciency of the limit switches (

fi g. 17

). Re-adjust if necessary.

- Check the condition of any moving mechanical parts like springs, beam lever, etc.

- Make sure the air intakes and the exhaust grids are not obstructed by foreign matters.

Warning

!

Do not replace parts of the barrier at your will and with own materials. Always address to your nearest dealer.

6.2 BLEEDING THE OIL-DYNAMIC SYSTEM

✂

SPACE RESERVED TO THE INSTALLER

PLEASE SUPPLY THIS PAGE TO THE USER

R

APRIMATIC S.p.A.

- Via Leonardo Da Vinci, 414 - 40060 Villafontana - Medicina (BO) - Italy

Tel. (39) 051-8850500 - Fax (39) 051-8850501

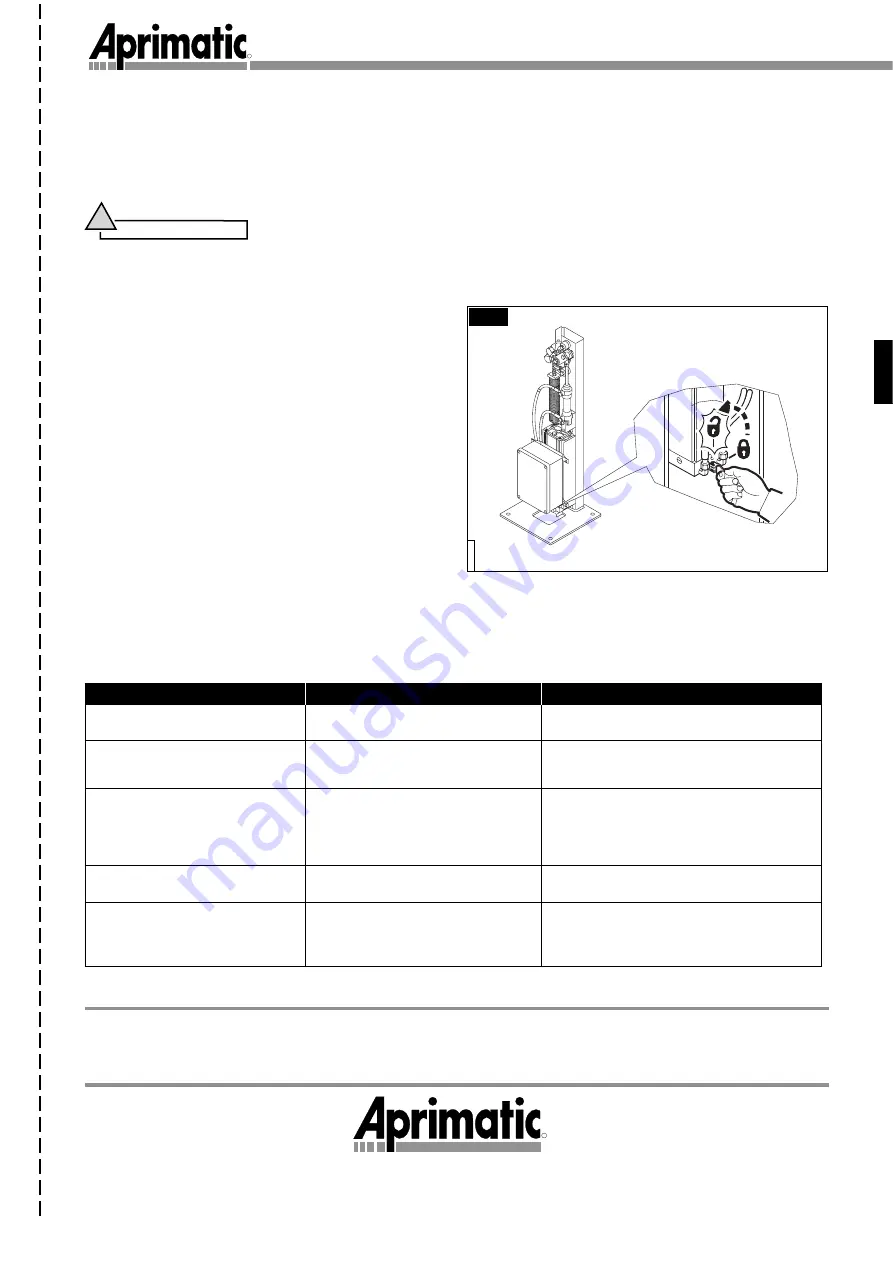

- Remove the piston from the supports. For a correct bleeding, the

piston cannot be mounted on the swinging beam (to allow for a

complete stroke of the rod in both directions).

- By the special dip-switch, disable the control of the hand-

unlocking micro-switch and reset the electronic appliance (so

that the adjustment takes effect).

After this prepping phase, proceed as follows:

- Operate the barrier in opening mode so that the cylinder rod

comes out completely. When it comes near the stroke end

position, open and close the manual unlocking device (fi g.31)

some times.

- Now operate the barrier in closing mode. Fully withdraw the rod

and repeat the above operations.

- Repeat both operations until the rod motion is even and smooth

and there are no jerks due to air bubbles.

- Reprogram the electronic appliance, refi t the piston and adjust

its stroke by adjusting the ball-joint and the oil-dynamic braking

(do not exaggerate in this adjustment).

AP031005

Fig.31

7.1 TROUBLESHOOTING

The following table shows the most frequent troubles that can occur and the interventions to be done to restore a proper functioning.

Trouble

Cause

Solution

The beam jerks during opening

and closing.

Wrong setting of the compensation spring.

Adjust the spring

The beam stroke is not complete during

opening and closing.

- Wrong intervention of the limit switches.

- Electronic deceleration.

- Oil-dynamic braking.

- Adjust the cams.

- Adjust the trimmers

- Adjust the oil-dynamic braking.

The beam tends to re-open and set to

25˚÷40˚ respect to the roadbed.

The manual unlocking device is not

fully closed.

- Check the external unlocking lever.

- Check the return spring of the unlocking lever

on the oil-dynamic control unit.

- Check the steel rope for foreign matters.

The beam hard moves at slow speed.

The manual unlocking device is not fully

closed.

Check the setting of the opening/closing

thrust valves.

Anomalous operation and/or alarm

condition.

Possible intervention of the safety sensors

or the signalling contacts.

- Ensure the dip-switches are set correctly.

- Check the proper functioning of all inputs

and outputs of the electronic appliance following

the LEDs' legend.