-8-

VII. REMOVING AND REPLACING THROUGH-HOLE COMPONENTS

(ENSURE THAT YOU ARE IN AUTO MODE)

A. Prepare board surface and component to be inserted appropriately

B. Ensure laser light locator is centered in wave nozzle

C. Enter program # desired (in edit mode)

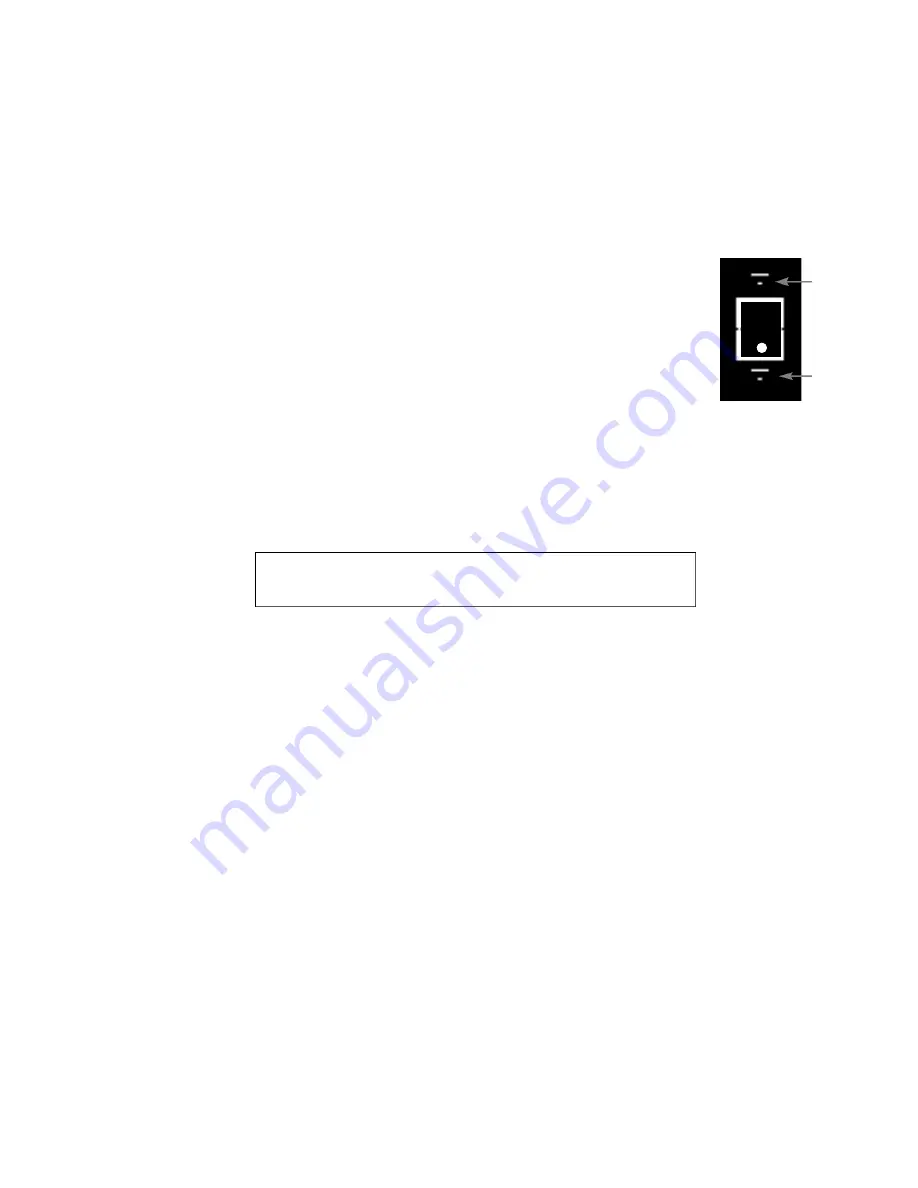

D. Ensure position switch is in Remove (down) position (see fig. 4)

E. Press foot pedal and wave will activate for wave time indicated

F. Remove component with tweezers while wave is activated

G.

(For GW-10A only, machine with blowoff feature):

1. Press position switch to Insert (up) position (see fig. 4)

2. Place blowoff nozzle flush onto holes on board

3. Press foot pedal and nozzle will activate for blowoff time indicated

4. Remember to press position switch back to Remove (down) position

before next step

H. Press foot pedal and insert part while wave is active

(apply flux if required)

I. Remove board to let solder joint cool

IX. SHUTDOWN

CAUTION

: After turning off main power, leave unit plugged in for 1 hour

minimum to cool unit.

A. Turn main power OFF at rear of unit. Last program will be saved for next startup.

X. MAINTENANCE

A. Solder Surface:

As a natural result of oxidation, a film of oxide (dross) will appear on the sur-

face of the solder. The oxide film protects and inhibits further oxidation of the

s o l d e r. But the accumulation of too much dross is not desirable.

Remove this dross daily using a stainless steel spoon or ladle. After removing

the dross, restore solder to correct level by adding solder bars to the pot.

B. Solder Quality:

In time the solder may become contaminated. Check the solder annually or

more frequently if necessary. A small sample may be sent to your local solder

supplier or to a qualified lab for analysis.

To remove copper contamination from solder, set the solder pot temperature to

369°F (187°C) and keep it ON for 8 hours. Excess copper-rich solder can be

skimmed off from the top of the solder. For better results repeat this procedure

2-3 times.

Note:

This procedure applies only to eutectic tin/lead alloy (Sn63/Pb37).

N O T E :

If you have no blowoff option, always leave

position switch in the remove position.

position switch

Insert

Remove