Shaker type dust collector

16

16 MAINTENANCE AND INSPECTION

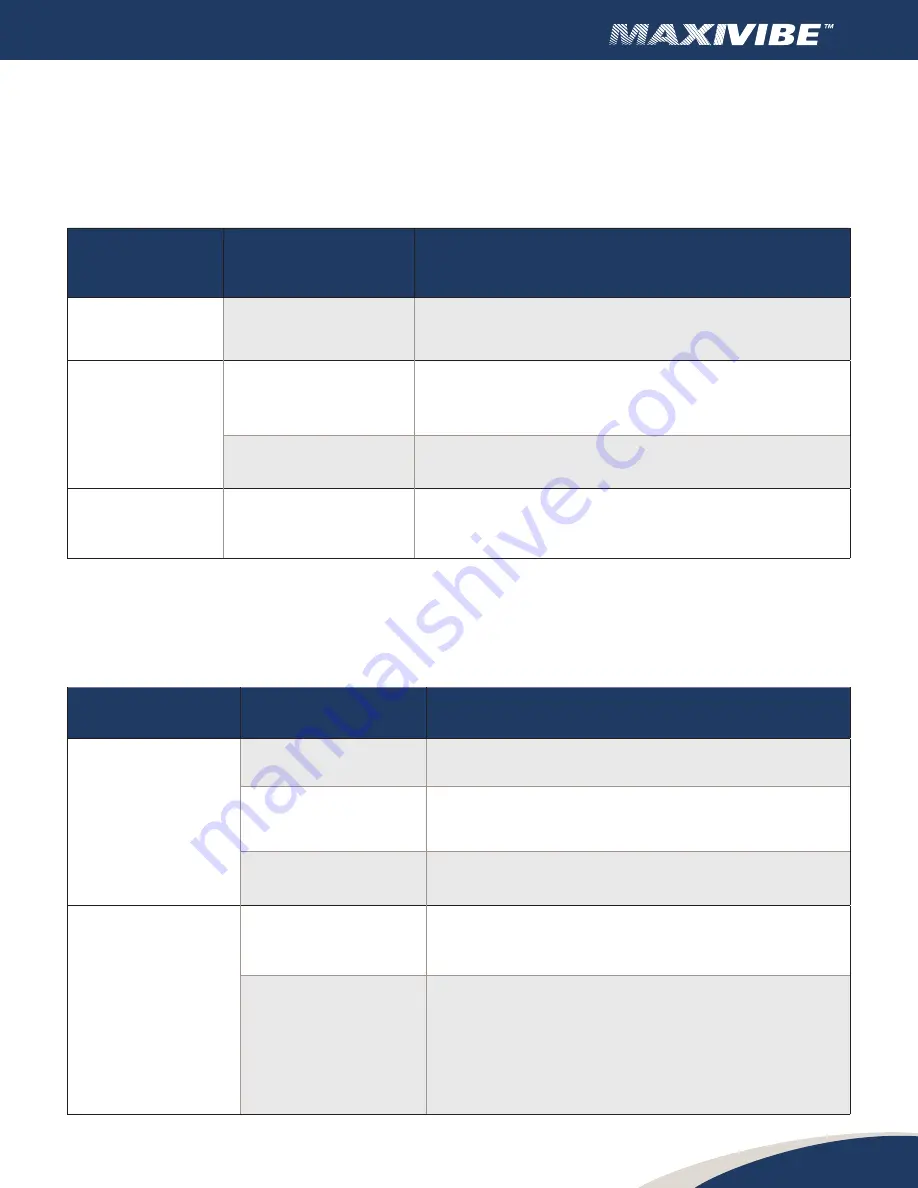

The chart indicated below shows different inspections and the frequency at which they should be

performed.

Frequency of

inspections

Components

Procedures

Daily

Dust collector

Examine air outlet for possible dust or smoke

accumulation. Refer to Troubleshooting section.

Weekly

Filter envelope

Check for leaks on the filter enveloppe. Repare or

replace if necessary. Ensure the filter enveloppe is

securely fastened.

Automatic shaker

Examine the shaker mechanism for any unusual

noise or vibration, broken parts or loose components.

Semi-annually/

Annually

Dust collector

Examine, clean and apply paint touch-ups if necessary.

If needed, lubricate the shaker and shaft rocking

system using lithium base grease.

Problem

Probable cause

Solution

Smoke or dust

escaping from the

clean air outlet

Filter envelope not

installed correctly

Tighten fasteners on filter frame

to ensure proper seal.

Leak in filter envelope

Repair or replace filter envelope.

Damaged seal

Repair or replace seal.

Drop in filter

efficiency

Shaker system not

fuctioning correctly

Examine the shaker system (motor, reducer, shaft,

frame) Repair or replkae if necessary. Increase

frequency of shaker actions.

High level of humidity

within the collector

Check humidity level or relative humidity within the

collector. A slightly higher humidity level may be cor-

rected by closing some gates and starting the cleaning

cycle. If the humidity level is too high, take necessary

measures to dry the air before it enters the collector.

17 TROUBLESHOOTING