Revised 4/23/19

Copyright © 2019 Aqua Creek Products All Rights Reserved

Revised 4/23/19

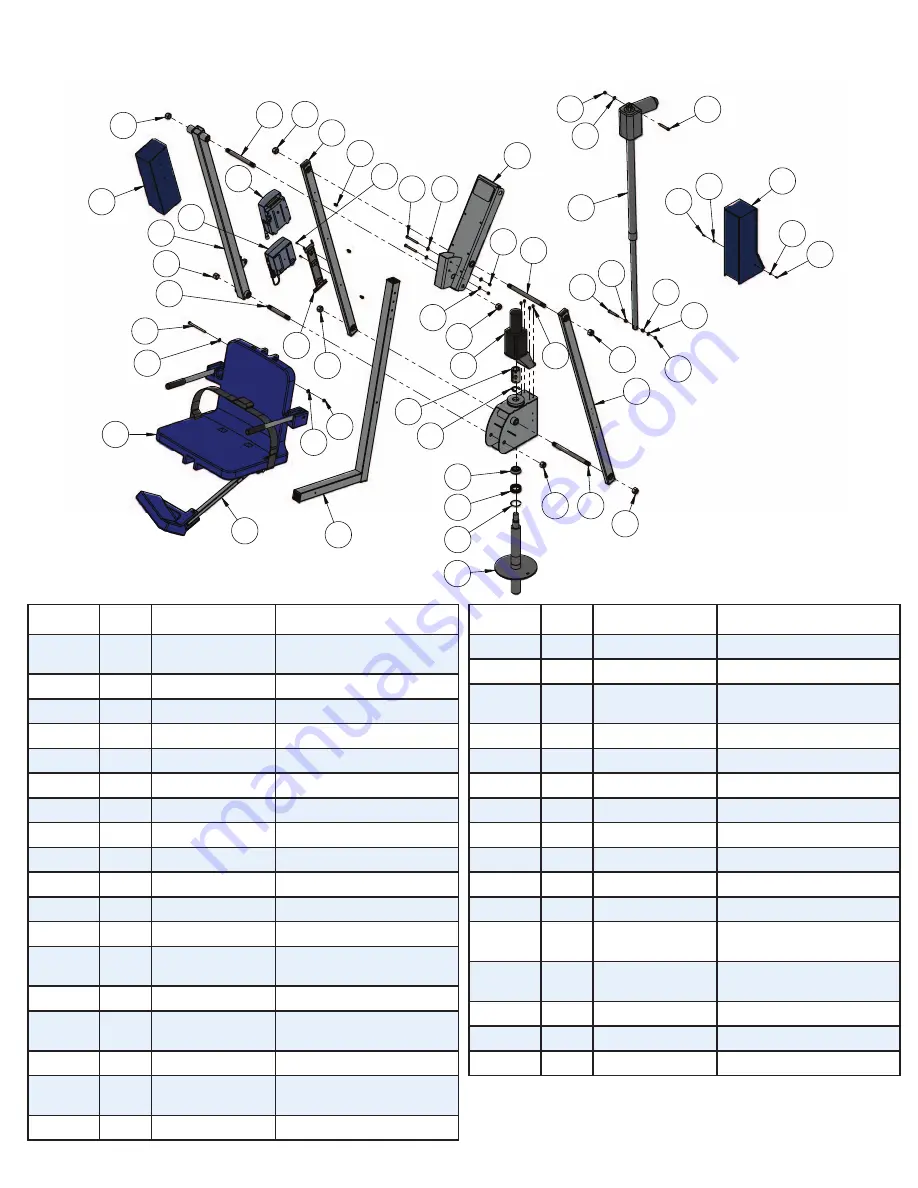

Mighty 600 Parts List

ITEM # QTY

PART #

DESCRIPTION

1

1

MTY-100WM-00

ANCHOR SPINDLE

WELDMENT

2

1

MTY-200WM-00

MAIN FRAME WELDMENT

3

2

MTY-400-00

CONTROL ARM ASSEMBLY

4

1

AMTY-600-00

TOP CASING ASSEMBLY

5

1

MTY-700-00

CHAIR CRADLE ASSEMBLY

6

1

AMTY-800-00

LIFTING ARM ASSEMBLY

7

1

MTY-900-00

MIGHTY MOTOR ASSEMBLY

8

1

SA-0904WDCAB

22” CHAIR ASSEMBLY

9

1

F-0904FRA

FOOTREST ASSEMBLY

10

1

341185-01

ACTUATOR, LINAK, 600MM

11

1

VCB10

VITO CONTROL BOX

12

1

VCP100-29800

VITO 24V BATTERY

13

1

GT10 (CONTROL

BRACKET)

VITO MOUNTING BRACKET

14

1

FW505520

NEEDLE ROLLER BEARING

15

1

93576A250

SPIRAL EXTERNAL

RETAINING RING

16

1

94751A785

EXTERNAL RETAINING RING

17

1

BEARING, ROLLER

LM67048

ROLLER BEARING & RACE

18

1

WBB263897

1” CLAMP ON SHAFT COLLAR

17

14

15

1

27

30

27

16

18

7

21

3

27

19

20

34

20

19

25

24

31

31

26

10

26

24

25

30

25

24

4

24

22

5

9

8

24

25

24

28

23

27

33

6

32

3

27

29

27

27

13

19

11

12

27

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

MTY-100WM-00

ANCHOR SPINDLE WELDMENT

1

2

MTY-200WM-00

MTY MAIN FRAME WELDMENT

1

3

MTY-400-00

CONTROL ARM ASSEMBLY

2

4

AMTY-600-00

MIGHTY 600 TOP CASING

ASSEMBLY

1

5

MTY-700-00

CHAIR CRADLE ASSEMBLY

1

6

AMTY-800-00

MIGHTY 600 LIFTING ARM

ASSEMBLY

1

7

MTY-900-00

MIGHTY MOTOR ASSEMBLY

1

8

SA-0904WDCAB

CHAIR, 22" WIDE SEAT ASSEMBLY,

BLUE

1

9

F-0904FRA

FOOTREST ASSEMBLY, STANDARD,

ANGLED, SPECIFY COLOR

1

10

341185-01

ACTUATOR, LINAK, 600MM,

MIGHTY STYLE

1

11

VCB10

CONTROL BOX, VITO, 2-PORT,

10AMP, BATTERY LEVEL INDICATOR

1

12

VCP100-29800

BATTERY, 24V BATTERY PACK,

SEALED, LEAD ACID, VITO

1

13

GT10 (CONTROL

BRACKET)

BRACKET, MOUNTING, VITO

1

14

FW505520

NEEDLE ROLLER BEARING

1

15

93576A250

SPIRAL EXTERNAL RETAINING RING

(MCMASTER)

1

16

94751A785

EXTERNAL RETAINING RING

(MCMASTER)

1

17

BEARING, ROLLER

LM67048

ROLLER BEARING & RACE FOR

REVOLUTION

1

18

WBB263897

1" CLAMP ON SHAFT COLLAR

(GLOBAL)

1

19

BSH 10 X 3-8

BOLT, 316 SS, 10-24 X 3/8 SHCS

4

20

WF 10

WASHER, FLAT, #10 SAE, 316 SS

2

21

BHW 1-4 X 3-8

BOLT, 1/4-20 X 3/8 HWH,

SERRATED, PATRIOT CASTERS

4

22

BH 5-16 X 3

BOLT, 316 SS, 5/16-18 X 3 HCS

2

23

BH 5-16 X 4 1-2

BOLT, 316 SS, 5/16-18 X 4 1/2 HCS

1

24

WF 5-16

WASHER, FLAT, 5/16, 316 SS

8

25

NN 5-16

NUT, 316 SS, NYLOCK, 5/16"-18

5

26

BS 3-8 X 2 18-8

BOLT, 18-8, 3/8 X 2 SHOULDER,

5/16-18 THREAD

2

27

NN 3-4

NUT, 316 SS, NYLOCK, 3/4"-10

8

28

TS 3-4 X 6

THREADED STUD, 18-8, 3/4-10 UNC

2A, BOTH ENDS PARTIALLY

THREADED

1

29

TS 3-4 X 8

THREADED STUD, 18-8, 3/4-10 UNC

2A, BOTH ENDS PARTIALLY

THREADED

1

30

TS 3-4 X 10 1-2

THREADED STUD, 18-8, 3/4-10 UNC

2A, BOTH ENDS PARTIALLY

THREADED

2

31

BRB FB-68-3

BUSHING, BRONZE FLANGE, 3/8 X

1/2 X 3/8 X 3/32

2

32

14530

CLIP, ROUTING, 3/8" DIAMETER FITS

1/4" DIAMETER

3

33

F-UBC

COVER, UNIVERSAL BATTERY

COVER

1

34

F-MTMC

MIGHTY MOTOR COVER

1

ITEM # QTY

PART #

DESCRIPTION

19

4

BSH 10 X 3/8

#10 X 3/8 SOCKET HEAD

20

2

WF 10

#10 FLAT WASHER

21

4

BHW 1/4 X 3/8

1/4-20 X 3/8 HEX WASHER

BOLT

22

2

BH 5/16 X 3

5/16-18 X 3 HEX BOLT

23

1

BH 5/16 X 4 1/2

5/16-18 X 4 1/2 HEX BOLT

24

8

WF 5/16

5/16 FLAT WASHER

25

5

NN 5/16

5/16-18 NYLOCK NUT

26

2

BS 3/8 X 2 18-8

3/8 X 2 SHOULDER BOLT

27

8

NN 3/4

3/4-10 NYLOCK NUT

28

1

TS 3/4 X 6

3/4-10 X 6 THREADED STUD

29

1

TS 3/4 X 8

3/4-10 X 8 THREADED STUD

30

2

TS 3/4 X 10 1/2

3/4-10 X 10 1/2 THREAD

STUD

31

2

BRB FB-68-3

3/8 X 1/2 X 3/8 X 3/32

BRONZE FLANGE BUSHING

32

3

14530

3/8 DIAMETER ROUTING CLIP

33

1

F-UBC

UNIVERSAL BATTERY COVER

34

1

F-MTMC

MIGHTY MOTOR COVER

13