ENGLISH

49

-

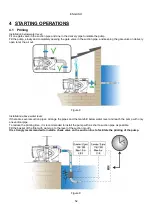

In “

fixed curve”

mode

(“Speed %”)

,

the setpoint (expressed as a percentage

“

%

”)

indicates the operating curve on

which you want to be positioned.

As can be seen in the figure, the operating point then moves following the trend

of the curve chosen, which is similar to the trend of fixed speed curves in traditional pumps.

Generally, when the work point falls below the maximum curve, the system reduces the absorbed power and thus

decreases the energy consumption.

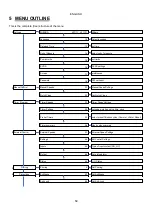

3.1.2 Command modes

The system can operate in three control modes: "Manual" mode and "Auto" mode.

In “Manual” mode:

-

The speeds are already pre-set but can be modified from the "Manual Speeds" menu or directly from

the home page in instantaneous mode (see par. 5.2)

-

the operator manually commands the switching on of the pump by pressing the keys from “

SET1

” to

“

SET4

” or “

QuickClean

”;

-

the LED next to the key that has been pressed lights up (for example, if “

SET1

” is pressed the LED

above this key is lit).

In “Auto con Timers” mode:

-

The speeds can be set from the "Timer Speeds" menu (par. 5.3).

-

switching on and off are automatically commanded by Timers, which can be programmed as desired

on a weekly basis (see par. 5.3 Timer Setting menu);

In these first two modes the pump acts as a Master and works alone through its integrated control.

In “Auto External” mode:

-

The speeds can be set from the " External Speeds" menu (par. 5.4).

-

Switching on and off is controlled by signals from an external control unit ("EXT").

-

The pump can be controlled with different types of signals: Digital/analog; single digital contact;

multiple digital contacts (see par 5.4 External Control/Settings/source speeds menu)

-

Operation can be: Exclusive with respect to internal programming, or priority with respect to Timers

that remain enabled but do not work as long as the external contact is active (see par 5.4 External

Control/Settings menu)

In this case, the pump works as a SLAVE with respect to a control unit or as a SEMI-SLAVE, where it is integrated

with a control unit that has priority over programming.

The “Auto” modes are disabled when the system leaves the factory.

To activate them, you must first of all configure the necessary parameters and then press the “Auto” key (the

respective LED lights up).

3.2 Rapid starting and stopping of the pump ("Manual" mode).

The pump leaves the factory and is delivered with Priming enabled: if the programming of Priming is not

changed (see par. 5.5),

when switched on for the first time, the pump may start at top speed.

Before pressing “RUN/STOP”, make sure that the valves are open, the pipes are not blocked, and keep

away from the filter and from parts that can be pressurized.

Check well all the IMPORTANT SAFETY WARNINGS AND RECOMMENDATIONS.

Once the first configuration has been carried out with the WIZARD (in conditions with the white LED blinking and the

“Auto” LED off), starting the pump is very easy:

•

press the key from “

SET1

” to “

SET4

” corresponding to the desired setpoint (e.g. “

SET1

”), or the “

QuickClean

”

key; the LED corresponding to the key pressed lights up, indicating the selection made;

•

press “

RUN/STOP

”.

At this point, switching on is enabled and the pump starts; the green running LED lights up, while the white LED

is lit with a steady light (indicating that now the system is active).

The system performs

startup

: the pump starts at a fixed speed (50%) for a few seconds.

Startup is necessary for the pump to switch on correctly, and it is always performed at each start of the

motor.

Priming is then performed (par.

5.5

), if it is enabled (according to factory setting).