ENGLISH

45

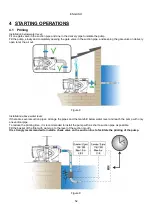

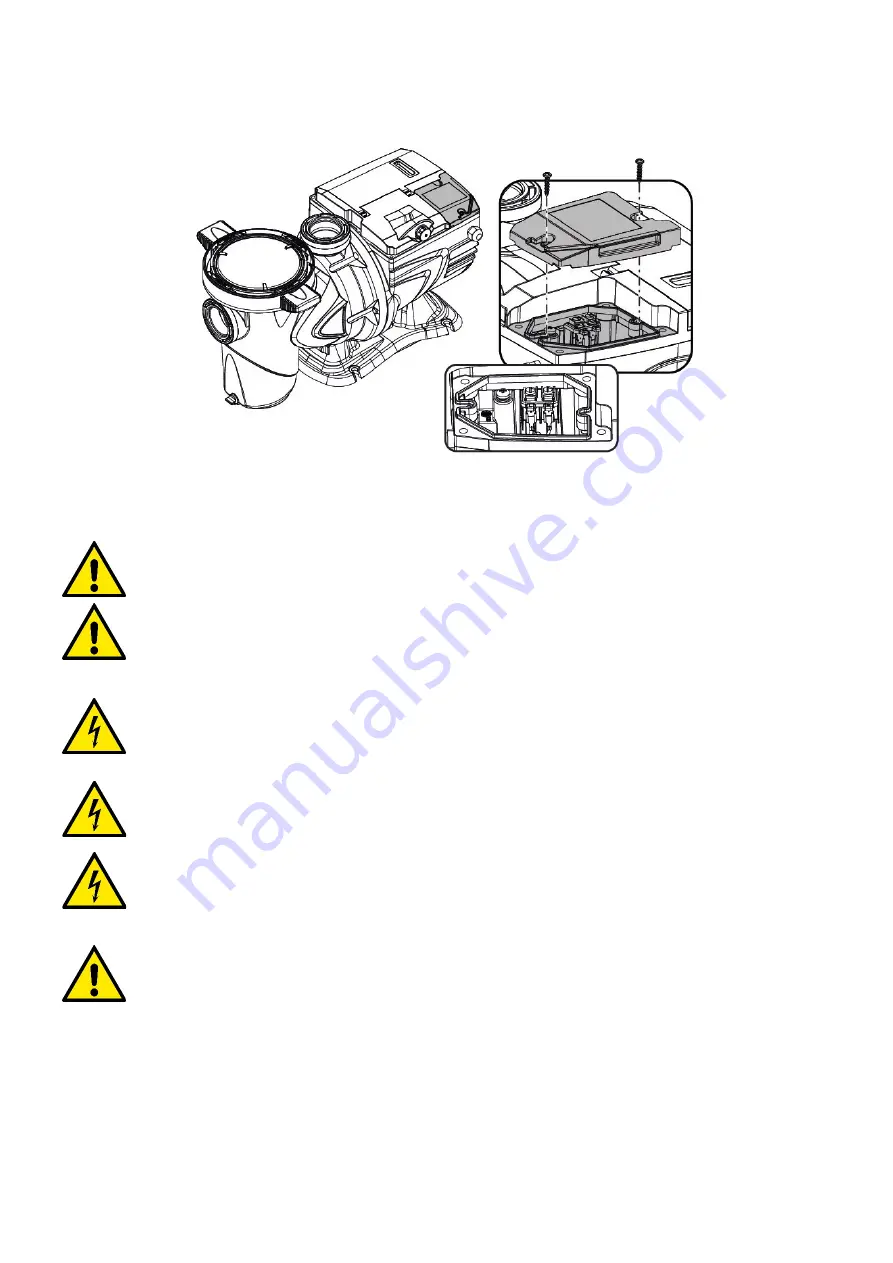

2.4 Electrical connection to the supply line

Figure 3

To improve immunity to the possible noise radiated towards other appliances it is recommended to use a separate

electrical duct to supply the product.

Attention: always respect the safety regulations!

Electrical installation must be carried out by an expert, authorised electrician, who takes on all

responsibility.

The system must be correctly and safely earthed as required by the regulations in force.

The mains voltage must be the same as that on the motor data plate.

Connect to the mains with a two-pole switch, with contact opening distance of at least 3 mm.

The thermal magnetic circuit breaker and the power cables must be correctly sized.

The leakage current to earth is max. 3.5 mA. It is recommended to use a type F differential switch. The

system must be adequately sized. The pump must be fed by means of an isolation transformer or a

differential switch, which must have a differential operating current no higher than 30 mA.

The mains terminals may still have dangerous voltage when the motor is stopped and for a few minutes

after disconnecting from the power mains.

The line voltage may change when the electropump is started. The line voltage may undergo variations

depending on other devices connected to it and on the quality of the line.

In the case of electropumps without a cable, provide power cables type H05 RN-F for internal use and

type H07 RN-F for external use, complete with plug (EN 60335-2-41). If the power cable is damaged, it

must be replaced by the manufacturer or by their authorised technical assistance service, so as to avoid

any risk.