SECTION 4: TROUBLESHOOTING

Problem

Possible Solutions

A. Neutralizer overcorrects upon installation or after replenishment.

1. The inlet bypass can be partially closed to allow untreated and treated water

to mix to obtain desired pH level. Periodically test treated water pH and open

bypass valve when pH begins to drop.

B. Neutralizer fails to increase pH upon installation.

1. Make sure bypass valve is closed.

2. Test water or have it tested via third party. If high hardness or total dissolved sol-

ids (TDS), seek alternate means of treatment such as feeding a solution of soda

ash or caustic soda.

In these cases contact our Customer Service Department

at 1-800-222-7880 for recommendations.

C. Neutralizer fails to increase pH after being in service.

1. Check fi lter bed for cementing or channeling. Break channeling or cementing

with stiff rod or tubing.

D. Excessive pressure drop.

1. Check untreated water for sediment, silt or sand. Install sand trap or multiple

cartridge fi lter prior to neutralizer.

IMPORTANT SERVICING NOTE:

Under normal circumstances removal of the fi ll-port head assembly should not be required. However, if it must be re-

moved, disconnect the plumbing attached to the bypass valve fi rst. Then, rotate the fi ll-port head assembly to the left or

counter-clockwise. Before attempting any disassembly, pressure should be relieved by shutting off water to the system

and opening a faucet. Upon reassembly, all o-rings should be lubricated with silicone grease. Reattach fi ll-port head

assembly by rotating to the right or clockwise until fi ll-port head assembly is seated to the tank hand tight. Reconnect the

plumbing to the bypass valve.

SECTION 5: SPECIFICATIONS

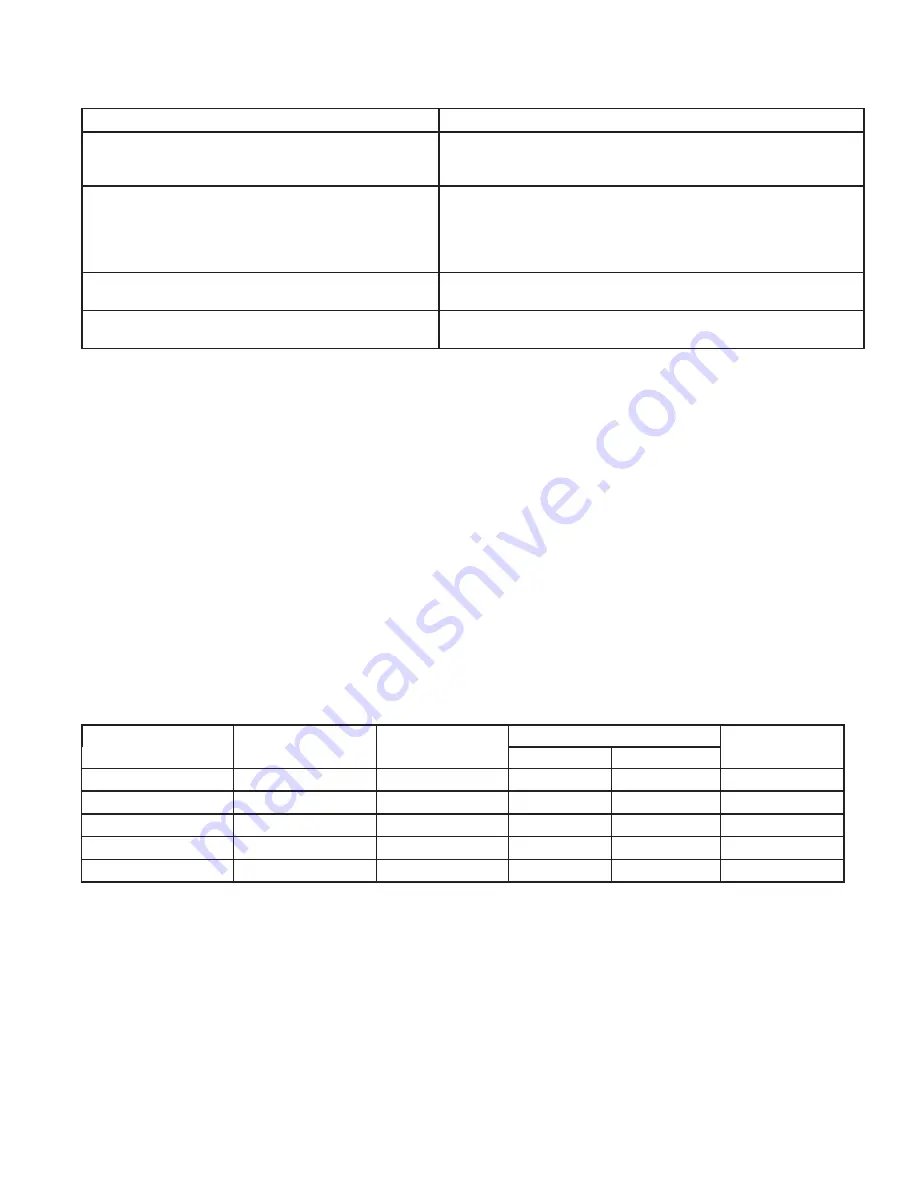

Model Number

Media (Cu. Ft.)

Pipe Size

Dimensions

Maximum

Flow Rate*

Diameter

Height

APUN101

1.0

1 in. (2.54 cm)

10 in (25.4 cm)

63 in (160.0 cm)

6 gpm (22.7 lpm)

APUN201

2.0

1 in. (2.54 cm)

12 in (30.5 cm)

68 in (132.1 cm)

7 gpm (26.5 lpm)

APUN301

3.0

1 in. (2.54 cm)

14 in (35.6 cm)

76 in (193.0 cm)

12 gpm (45.4 lpm)

APUN100-LM

None included

1 in. (2.54 cm)

10 in (25.4 cm)

63 in (160.0 cm)

6 gpm (22.7 lpm)

APUN200-LM

None included

1 in. (2.54 cm)

12 in (30.5 cm)

68 in (132.1 cm)

7 gpm (26.5 lpm)

Maximum operating temperature 110°F (43.3°C); Maximum operating pressure 20-100 psi. Specifi cations subject to change without notice.

NOTES:

*

The lower the pH (acidity) of the water being treated, the greater the attrition rate of the media and the slower the water should pass

through the bed. The unit should be sized according to the level of pH and existing fl ow rate.

5

Summary of Contents for APUN100-LM

Page 2: ......