12

Contact Your Sales Representative for Further Assistance.

6. Fan Motor Becomes Excessively Hot

The main fan motor normally becomes very hot to the touch. However, if it gets so hot that it

begins to smell or smoke or the power cord becomes hot, discontinue operation and consult

an electrician to properly evaluate the problem.

7. Electrical Breaker Tripping

If the electrical breaker trips off, there is an overload in the system and there may be a

serious motor problem. Turn off all other devices connected to the same circuit. If the

breaker continues to trip, the motor is probably in need of repair. Consult an electrician

for evaluation.

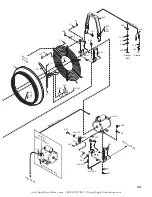

8. Fan and/or Motor Vibration

A.)

If the fan unit begins vibrating severely, first be sure the blade assembly is fully engaged

and securely tightened on the motor shaft. Next, inspect the blade assembly, particularly

the ends of the blades. Look for wear or cracks - replace as necessary. Look for deposits

of calcium or minerals - clean and remove mineral deposits and/or calcium.

B.)

If the vibration seems to be coming from the motor, first check that the motor mounting

hardware is securely tightened. If hardware is secure, remove the blade assembly and

operate the motor without the blade. If vibration continues, the motor has a serious

mechanical problem and probably needs to be replaced.

9. Liquid Spilling From Fan Housing or Sump Tank

If liquid builds up inside the housing, the drain tube is clogged. Clean debris from around

the drain inside the housing and flush drain tube. If liquid overflows from the sump, check

the floatvalve assembly (400-012) for any impediments preventing the valve from closing

propertly when tank becomes full. Replace if necessary.

10. Plumbing Leaks

Un-thread fittings and clean both the male and female threads. Apply new thread tape

(approximately 2-3 wraps) and reconnect. If a tube fitting is leaking, tighten the cap - no

more than 1 turn past finger tightened. If the leak persists, replace the tube fitting insert.

T

ROUBLESHOOTING

(

CONT

.)

BEFORE INSPECTION AND/OR SERVICE

DISCONNECT AND LOCK OUT POWER SOURCE.

WARNING

www.JigglyGreenhouse.com | (800) 878-7829 | Sales@JigglyGreenhouse.com