XE 360

I

NSTALLATION

USING A LADDER TO HANG THE GT 500-HS IS DANGEROUS.

USE PROPER LIFTING EQUIPMENT LIKE A SCISSOR LIFT.

DANGER

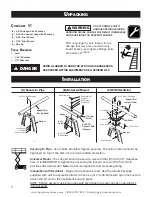

(A) Secure to Pipe

Hanger

Support Bar

(not provided)

Support Bar

(not provided)

1/4-20 U-bolt Package

Oscillator

1/4-20 U-bolt Package

(B) Universal Mount

Drill 5/16"

Clearance Hole

in Support

(C) With Oscillator

Anti-

seize

Required Use

Flat, Level

Surface

7

(1) 1/4-20 Hanger U-bolt Package

(1) 5/16-18 Universal Hanger Bolt Package

(1) 5/32" Allen Wrench

(1) 3/32" Allen Wrench

(6) Wire Tie

►

Level

►

7/16" Wrenches

►

1/2" Wrenches

U

NPACKING

C

HECKLIST

þ

T

OOLS

R

EQUIRED

After unpacking the unit, inspect for any

damage that may have occured during

transit. Make sure to tighten fittings, bolts,

etc. before operation.

DO NOT OPERATE UNIT IF

DAMAGED DURING SHIPPING,

HANDLING OR USE. DAMAGE MAY RESULT IN BREAKAGE

AND CAUSE INJURY OR PROPERTY DAMAGE.

WARNING

Lock Washer

Finish Nut

Nylon Lock Nut

Hanger

Nylon Lock Nut

Finish Nut

Lock Washer

Flat Washer

5/16-18

Bolt Package

Hanger

(2) 1/4-20 Bolt

Nylon Lock Nut

Lock Washer

Finish Nut

Nylon Lock Nut

Securing To Pipe

- Use U-bolts provided. Tighten securely. The nylon locknut should be

tightened on top of the first nut to provide added protection.

Universal Mount

- The support should be secure, level and flat. Drill a 5/16" clearance

hole. It is IMPORTANT to tighten the second nylon locknut on top of the first nut to

provide added protection.

Note:

Anti-seize applied to bolt prevents galling.

Installation with Oscillator

-

Support bar should be level. Use the U-bolts Package

supplied with unit to secure Oscillator to bar. Use (2) 1/4-20 bolts with nylon lock nuts to

attach the GT unit to the oscillator's support plate.

NOTE: Tighten securely using two opposing wrenches to prevent stress on oscillator's

internal gears.

www.JigglyGreenhouse.com | (800) 878-7829 | Sales@JigglyGreenhouse.com