11

t

roubleShootinG

BEFORE INSPECTION AND/OR SERVICE,

DISCONNECT AND LOCK OUT POWER SOURCE.

WARNING

1. Poor/Inconsistent Fogging Output

A.)

Inconsistent or spotty chemical coverage usually occurs because the fog volume output

is too high. Ideally, fog will disappear when fogging at rates near 3 GPH. To check for fog

volume output, refer to Maximum Pre-set Flow Rate (See

Page 6

).

B.)

Inconsistent fogging coverage may be circulation-related. To maximize circulation, check

inside tank around pumps, making sure they are both free from build-up.

C.)

Reservoir may be clogged. Fluid entering a clogged reservoir will spill out the back of the

blade instead of entering the passageways of the fan blades (also ref.

6b

). To

clean, remove the blade assembly from the motor shaft and disassemble. Next, flush the

reservoir under a sink. Check and clear the passageways for each individual blade as

well. Reassemble and reattach.

D.)

It is possible for an air pocket to become caught within the plumbing. If you think

this is occurring, throttle the flow control valve to wide open a few times to expel any

trapped air. If the problem persists, check your pre-set flow rate valve (refer to page 6

Factory Pre-set Flow Valve). The CRSM will automatically prime the feed pump, but if the

pre-set flow rate valve is in a fully closed position, the automatic priming will not occur,

resulting in trapped air and poor/inconsistent fogging output.

E.)

Consistency of fogging output greatly depends on the consistency of the cleaning

procedures (See Page 10). Check strainer, plumbing, and inside of tank for dried

sediment or clogs.

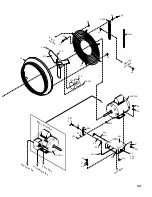

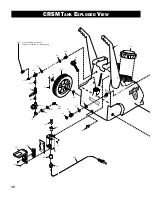

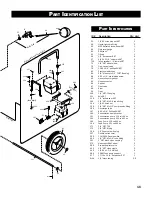

2. Blades Rub Against Venturi

A.)

To make a horizontal adjustment, loosen the 4 bolts (Part #56) at the base of the main

fan motor and shift motor side to side until centered. Retighten bolts.

B.)

To make a vertical adjustment, detach the housing by removing the 6 small bolts (Part

#54). Next, loosen 4 bolts (Part #52) and make necessary adjustments. Retighten bolts

and reattach housing.

3. Fan and/or Pumps Do Not Operate

Check voltage requirements on unit and electrical supply. Have a certified electrician check

for live receptacle, plug, power line, and toggle switch. If the fan works but one of the pumps

does not, look for any loose connections inside the main motor's junction box. If there are no

loose connections, the pump is probably damaged and should be replaced.

4. Fan and/or Motor Vibration

If the fan unit begins vibrating severely, first be sure the blade assembly is fully engaged and

securely tightened on the motor shaft. Next, inspect the blade assembly, particularly the

ends of the blades. Look for wear or cracks - replace as necessary. Look for deposits of

calcium or minerals - clean and remove mineral deposits and/or calcium. Also, check that

the motor mounting hardware is securely tightened.