► Un-crate carefully and position CRSM on

level ground.

► Save crate and packing materials until

evaluation and testing are complete.

► Read manual carefully and understand all

instructions.

► Do not connect power until after thorough

inspection and filling the sump with liquid.

► After filling the unit with some liquid, inspect

for leaks.

► Never operate without liquid in tank.

► Be sure guards are securely in place and

warnings are clearly visible.

► Check power supply for correct voltage.

G

ettinG

S

tarted

U

npacking

c

hecklist

DO NOT OPERATE UNIT IF

DAMAGED DURING SHIPPING,

HANDLING OR USE. DAMAGE MAY RESULT IN BREAKAGE

AND CAUSE INJURY OR PROPERTY DAMAGE.

WARNING

e

lectrical

GROUND FAULT RECEPTACLES

ARE RECOMMENDED AND MAY

BE REQUIRED BY LOCAL AND/OR NATIONAL CODE.

WARNING

USE OF AN EXTENSION CORD IS

NOT RECOMMENDED.

IF NECESSARY, REFER TO FIG. 12.

NOTICE

4

EXTENSION CORD SPECIFICATIONS*

FOR SINGLE FAN USE ONLY • (AWG - American Wire Gauge)

Voltage

25 to 50 ft.

50 to 100 ft.

115/230

16 AWG

14 AWG

Fig. 12

*Grounded and suitable for outdoor use.

U

nit

p

reparation

EN

SURE THE BLADE ASSEMBLY

IS FREE & CLEAR FOR

START-UP (HIGH-SPEED ROTATION).

WARNING

Adjustment Pin

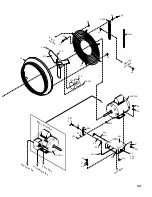

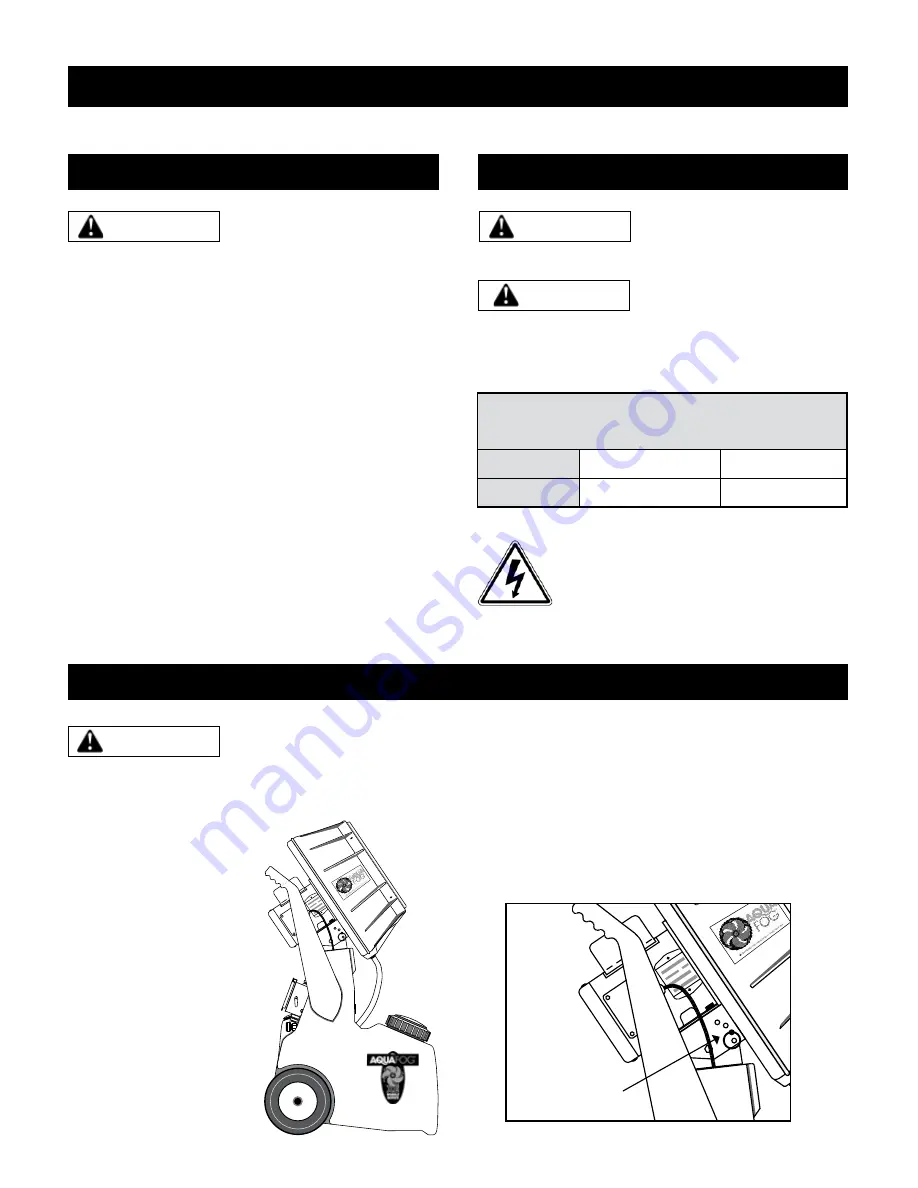

The CRSM is equipped with a four position pivoting

fogging head with 15º intervals up to 45º (see

Fig. 1

)

Propelling the fog upward allows more time for the

particles to evaporate, keeping floor areas drier.

When making an adjustment, support the weight of

the fogging head off of the pin for easy removal.

Locate a level, stable

area to place the

CRSM. If there's a

slight grade, blocking

the wheels may be

necessary to keep unit

secure.

Visually check to

make sure the fan

blades can rotate

freely. There should

be approximately 1/4"

space between the

venturi pins and the

blades.

Fig. 1