5

e

valuation

/ c

ontrolS

/ i

nStallation

BEFORE TESTING FAN MAKE SURE ALL OBJECTS ARE OUT OF THE

ROTATION PATH OF THE FAN BLADES.HIGH-SPEED WARNING.

KEEP HANDS

CLEAR!

MAKE SURE GUARDS ARE INSTALLED OR UNIT IS OUT OF REACH.

DANGER

►

For first-time evaluation, fill tank (with water only) about quarter full.

►

Connect to power supply.

►

BUMP START CRSM and check for proper fan blade rotation (clockwise if looking at front of unit). If incorrect,

find rotation connection changes on the motor's electrical schematic.

►

Turn on the unit and listen for any possible abnormalities, such as the blades rubbing against the

venturi or any objects. Make re-adjustments if necessary.

►

Evaluate fog quality adjusting the output by using the flow control valve. (See

Fig. 2

).

After starting, it generally takes several seconds for the liquid to reach the atomizing fan.

The volume of fog can be regulated by adjusting the Flow Control

Valve. (See

Fig. 2

)

Particle size is smaller/drier at lower outputs, so it is wise to

operate the unit at a lower output for longer periods of time rather

than high outputs for short periods of time.

At the base of the plumbing is an in-line strainer with a removable

cap. Occasionally check inside and flush any sediment from the

screen.

The Hose Connection is used to supply fresh water to the unit and is

controlled by an internal float valve assembly.

Rain-tight Double-throw On - Off switch box.

Upper Switch - Fan Motor

Lower Switch - Feed Pump

A Fluid Level Gauge to aid in monitoring the tank's 18 gallon capacity.

Back Controls

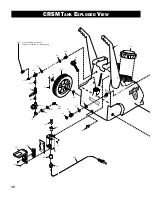

A) Manual Treatment

Fast / Easy setup. Simply

fill the unit's tank with pre-

mixed chemical concentrated.

Wettable powders can be used

if kept well stirred.

B) Dosing with Feed Pump

Can be arranges if using liquid

concentrated product. A feed

pump will provide accurate flow

rate of chemical product.

S

etup

A timer should be used to turn off the

CRSM at the appropriate time. If a

Metering Pump is installed it should be

controlled by the timer.

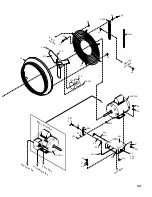

Water Connection

Optional connection port for a feed pump.

Dosing concentrated liquid chemical product

into the stream of fresh water traveling to

the fogging head.

►

Fresh

Water

Storage

Atomized

Mixture

Fig. 2

*

Connection for metering pump (3/8" fitting provided).

▼

▲

OFF

ON

Fluid Level Gauge

On/Off

Fan Motor

Key

Hose Connector

On/Off

Pump

Inline

Strainer

Flow Control

Valve

*Metering

Pump Inlet