- 69 -

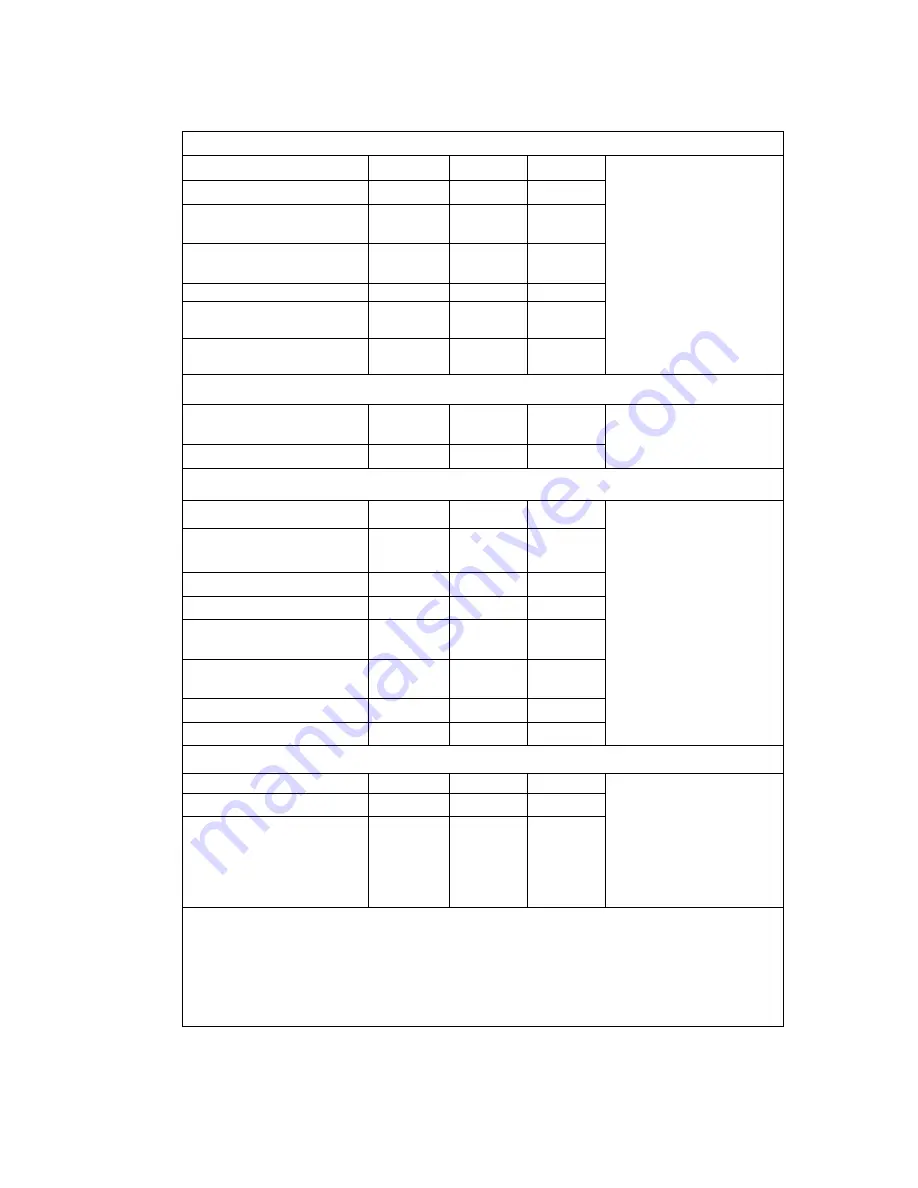

ELECTRICAL

Spark plug

I

R

(1)

(1) By repair shop.

(2) Inspect once per

month.

(3) Daily rinse and clean

water sensor switch after

salt water use.

Battery and fasteners

I

I

(2)

Electric connectors and

fasteners

I

I

Engine cut-off switch and

stop switch

I

I

Main switch

I

I

Bilge pump automatic

sensor switch

C, I

(3)

Bilge pump and manual

switch

I

STEERING SYSTEM

Steering cable and

connections

I

I, L

(1)

(1) By repair shop.

Steering nozzle

I

I

(1)

PROPULSION SYSTEM

Jet pump

C

(1)

(1) Daily cleaning jet

pump by spraying water in

its inlet and outlet and

then apply a coat of an

anti-corrosion lubricant

after salt water use.

(2) Replace seals at 200

hours (irrespective of

number of years). See

NOTE 1 at the end of

maintenance schedule

table.

(3) By repair shop.

Drive shaft rubber boot and

mechanical seal

(2)

I

I

(3)

Impeller shaft seal

(2)

I

(3)

Stator cone cap "O" ring

I

(3)

Impeller and impeller wear

ring clearance

I

I

Sacrificial anode (if so

equipped)

I, R

Pump mounts

I

I

Ride plate seal

I

I

Hull

Hull

I

I

(1) Daily rinsing after salt

water use.

(2) Every 10 hours in salt

water use.

Engine compartment seals

I

I

Engine compartment

(spray water repellent to

fiber glass hull in engine

compartment)

C

(1)

, L

(2)

C

(1)

, L

(2)

A: ADJUST

C: CLEAN

I: INSPECT

L: LUBRICATE

R: REPLACE

Note 1: Inspect for possible leak or damage on oil seal or water seal, and drive shaft

sleeve surface.

Summary of Contents for JETANGLER

Page 2: ...AQUANAMI LLC 809 Grandview Drive Hampstead NC 28443 USA...

Page 9: ...7 SAFETY INFORMATION...

Page 24: ...22...

Page 30: ...28 Label 2 Label 3 Label 4...

Page 31: ...29 Label 5 Label 6...

Page 32: ...30 Compliance Labels Label 7 Label 8...

Page 33: ...31 Label 9 Label 10...

Page 41: ...39 WATERCRAFT INFORMATION...

Page 67: ...65 MAINTENANCE INFORMATION...

Page 95: ...93 TECHNICAL INFORMATION...

Page 102: ...100 TROUBLESHOOTING...

Page 106: ...104 WARRANTY...

Page 113: ...111 CUSTOMER INFORMATION...