☎

CAN (866) 766-3426 |

☎

US (866) 877-6637

7

If running through winter conditions, check regularly to make sure it is functioning properly and ice is not preventing water

from reaching the pump. In the event of a power failure, the pump should be removed to prevent any freeze damage to the

pump or the piping.

If concerned about possible freeze damage, disconnect and remove the pump. Be careful not to lose the flat rubber washer.

Clean with fresh water and store the pump in a frost-free location. If needed, use Aquascape Pump Cleaner Maintenance

Solution (#91143) to remove excessive buildup.

Winter Application

• Reduced water flow

– Pump or plumbing may be clogged. It may be necessary to clean the pump cage screens and impeller.

• Pump hums but doesn’t push water

– The pump or plumbing may be clogged.

It may be necessary to clean the pump cage screens and impeller.

Remove the water chamber cover and inspect and clean the impeller rotor assembly and internal pump body.

Make sure nothing is blocking or wrapped around the impeller.

– Make sure the pump is receiving the correct voltage.

• Pump not working

– The ground-fault circuit interrupter (GFCI) may have tripped.

– The pump is not receiving the correct voltage.

Troubleshooting

(Ex. 20). Removing scale build-up will allow your pump to

run like new again.

Replacing the Impeller/Rotor Assembly

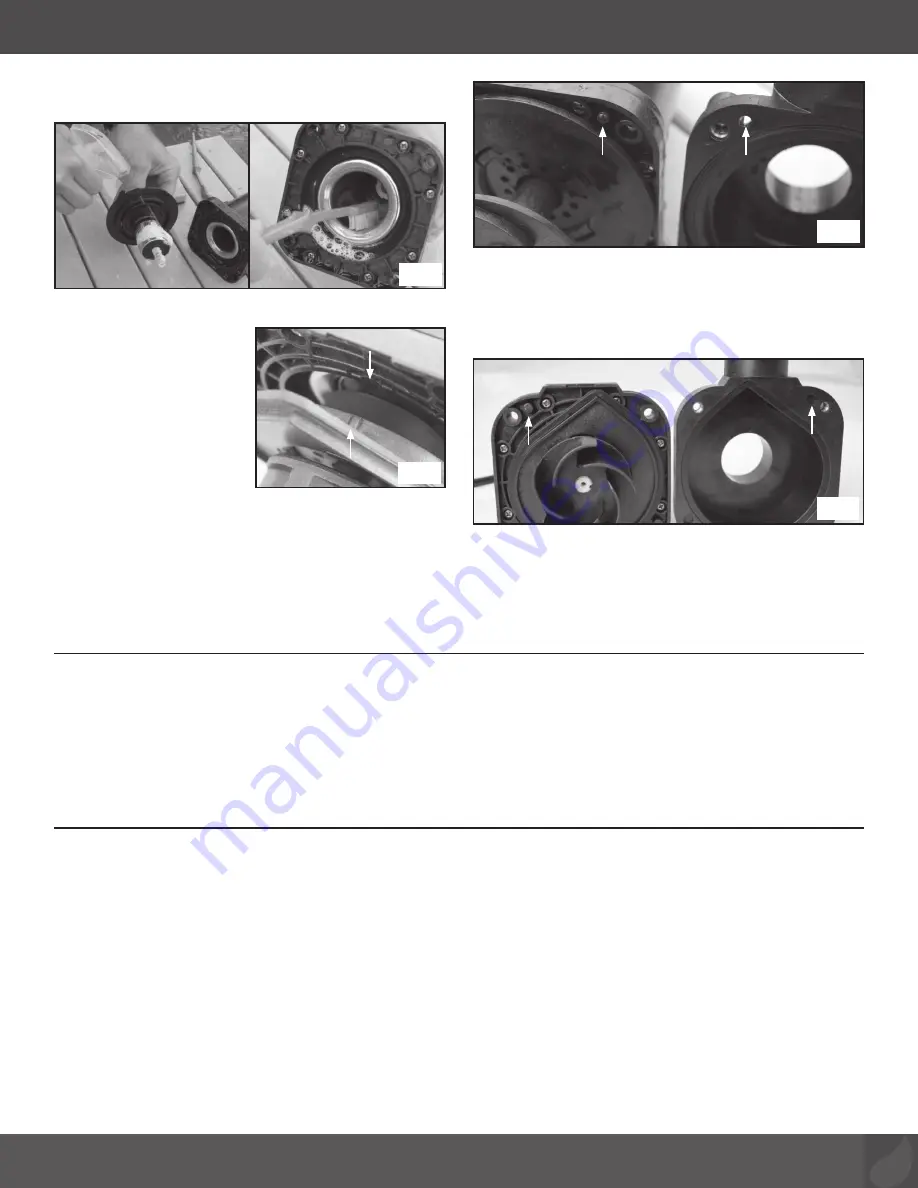

• For Model 3600 and

5200: When replacing the

AquaForce 3600 or 5200

rotor-impeller assembly into

the pump chamber, note

the proper orientation. The

raised key on the impeller

face plate should be lined

up with the groove in the

pump housing (Ex. 21).

• For Models 1000, 1800 and 2700: The 1000, 1800 and

the 2700 models allow the impeller-rotor assembly to be

inserted into the pump body with no special alignment

guides needed (Ex. 22).

Ex. 20

Ex. 21

Raised key

Groove

• AquaForce 5200 ready for reassembly: The water

chamber cover will only fit back onto the pump with the

top of the tear-drop shapes lining up, along with matching

the hole in the cover with the pin on the face of the pump

motor flange (Ex. 23).

Replacing Pump in Cage

• Replace the pump into the lower cage and secure in place

with the brackets. Also replace the power cord in the

strain relief.

• Reinstall filter cage and close all 5 clips.

Ex. 22

Pump

flange pin

Pump water

cover hole

Ex. 23

Pump

flange pin

Pump water

cover hole