24 /

JACK

Instruction

Manual

3789833-20200901

Original Instruction

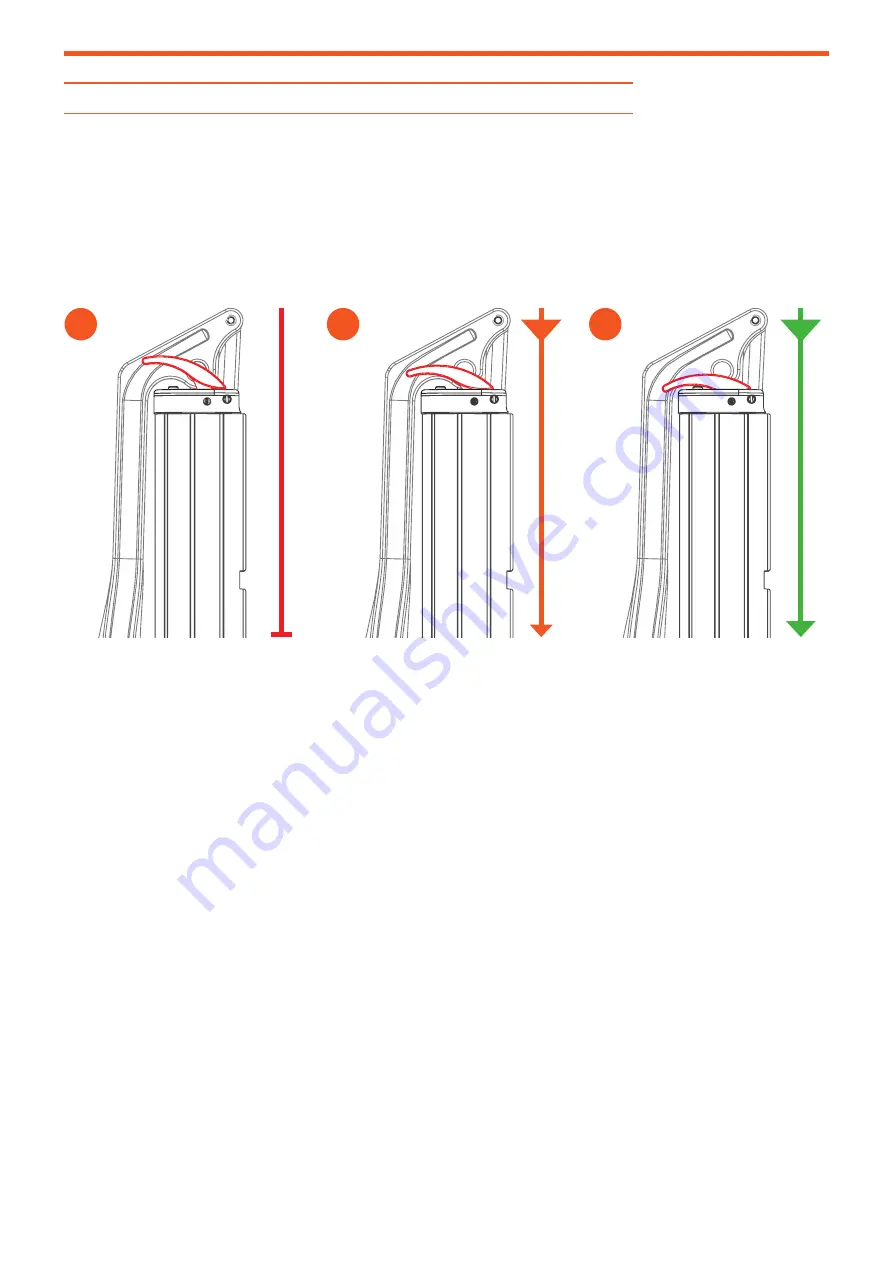

3. DESCENT CONTROL

The initial two-thirds of the release lever travel is intended for slow lowering

of the loaded Jack. The final third of the lever travel is for fast lowering of the

unloaded Jack. Do not use the fast lowering speed while the Jack is loaded.

1

2

3

1. CLOSED

2. SLOW

3. FAST

Summary of Contents for Jack

Page 15: ...JACK Instruction Manual 15 Original Instruction SAHARA SUMMIT BAR COMMERCIAL DELUXE BAR ...

Page 16: ...16 JACK Instruction Manual 3789833 20200901 Original Instruction REAR CARRIER SUMMIT RSTB ...

Page 17: ...JACK Instruction Manual 17 Original Instruction REAR BUMPER ...

Page 19: ...JACK Instruction Manual 19 Original Instruction ...