Use and Maintenance Manual

Page 35

8.

MAINTENANCE

In case of damage, the operator

must stop the machine, take out

the ignition key, come down from

the tractor and determine the en-

tity of the problem and then pro-

ceed with any work required on

the machine.

Please note that all maintenance operations must be carried

out by qualified and trained workers, with the machine off.

it is also very important that all maintenance and repair work is

not carried out outside but in a specifically equipped workshop.

During use, regulation, mainte-

nance, repair or movement, the

operator must use adequate per-

sonal protective equipment.

Before starting any maintenance operation, the following in-

structions must be followed:

During maintenance, the machine must be placed on a flat

and even surface;

•

Turn off the tractor engine, engage the drum brake and

remove the ignition key from the panel;

•

Always make correct use of PPE (protective shoes, over-

alls and gloves, anti-dust mask);

•

Use all the accident-prevention means relative to the op-

eration under way;

•

Where using compressed air to clean the machine, you

must use protective eyewear;

•

When machine maintenance requires access to parts

that cannot be reached from standing on the ground, or

points higher than 1.50 m, use ladders or platforms that

comply with the regulations in force;

•

Do not carry out unfamiliar reparations. Always follow in-

structions and where they are missing, contact the man-

ufacturer or expert personnel;

•

Do not use lifting points other than those specified;

•

Make sure that the chosen lifting device is suitable for

the operations to be carried out and complies with the

safety regulations;

•

Do not keep the engine of the machine running in closed

areas with no ventilation system able to eliminate the ex-

haust gases building up in the air;

•

Avoid long and repeated skin contact with fuels/lubri-

cants/fluids, since these could generate inflammation or

other skin pathologies;

•

Do not ingest fuels/lubricants/fluids. In case of acciden-

tal contact with the eyes, carefully wash the area with

water;

•

Do not weld in closed areas or with inadequate ventila-

tion;

•

Do not weld on or near painted surfaces to avoid the

propagation of toxic fumes. Remove the paint with spe-

cific products, then wash the surface and leave to dry;

•

When using compressed air, always wear goggles with

side shields, and a mask in order to avoid the danger of

personal lesions due to dust particles. It is recommend-

ed that the machine be cleaned in ventilated areas.

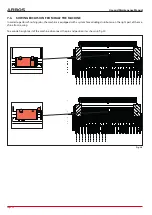

FOR ANY MAINTENANCE OPERA-

TIONS WHICH NEED TO BE CAR-

RIED OUT BELOW THE SEEDER,

CORRECTLY POSITION THE ME-

CHANICAL BLOCKS PROVIDED 16

- 19 ON THE HYDRAULIC PISTONS

AND LOWER THE MACHINE.

Summary of Contents for MEK-X250

Page 2: ......

Page 4: ...Use and Maintenance Manual...

Page 38: ...Use and Maintenance Manual Page 38...