info@matermacc.it

Use and maintenance handbook

Page 07

1.7.

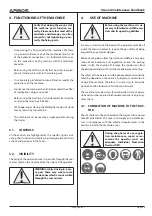

AFETY AND ACCIDENT-PREVENTION

RULES

Correct use of the appliance, careful attention paid to the

rules listed below and strict application of all precautions to

prevent any dangerous of accidents or hazards, will ensure

better long-term operation of the appliance and will reduce

the likelihood of faults.

Arbos group S.p.A. declines any responsibility, objective or

subjective, where the rules governing behaviour as provided

in this manual, are disregarded.

•

The machine is not recommended for use in fields other

than the agriculture sector.

•

The machine must be used by a single operator driving

the tractor.

•

Any use which differs from the one specified is consid-

ered improper.

•

The machine must only be used by authorised, instruct-

ed and properly trained personnel. The assigned opera-

tor, in addition to having read the instructions provided

in this manual, must undergo adequate training on the

use of the machine and must have a valid driving licence.

The operator must contact the manufacturer should

they have any doubts on the use of the machine with or

understanding the present manual.

•

The manual must be kept somewhere so that it is acces-

sible and close to hand, so that the operator can consult

it at any time, where necessary. If the manual is mispla-

ced or damaged, contact the Arbos group S.p.A. Com-

pany for a replacement copy.

•

The operator must ensure that during operation, no per-

sons or animals are found in close proximity of the ma-

chine. Never operate the machine near persons stopped

or in transit within the machine operating area.

•

Do not use the machine if suffering from fatigue, illness

or under the effects of alcohol, prescribed medication or

drugs.

•

This machine is only used during the day. If there is an

exceptional requirement to use the machine at night or

in conditions of reduced visibility, the lighting system

provided with the tractor, or an auxiliary lighting system,

must be used.

•

Any arbitrary modification made to the machine releases

Arbos group S.p.A. from all liability for damages or inju-

ries which may be experienced by operators, third par-

ties and objects.

•

Before you switch the machine on, check it every time.

•

Arbos group S.p.A. cannot list every improper use which

may reasonably lead to a potential hazard.

•

The labels applied to the machine provide important

instructions: please observe them to ensure your safety.

•

Make sure that the emergency pictograms are legible.

Clean them and replace them, when necessary, with new

labels.

•

Before using the machine, ensure that all safety devices

are in the correct place and in good condition; where

they are faulty or damaged, immediately replace them.

•

Before descending from the tractor and before every

maintenance operation, activate the stationing parking

brake, turn the engine off, remove the ignition key from

the dashboard and take care of it.

•

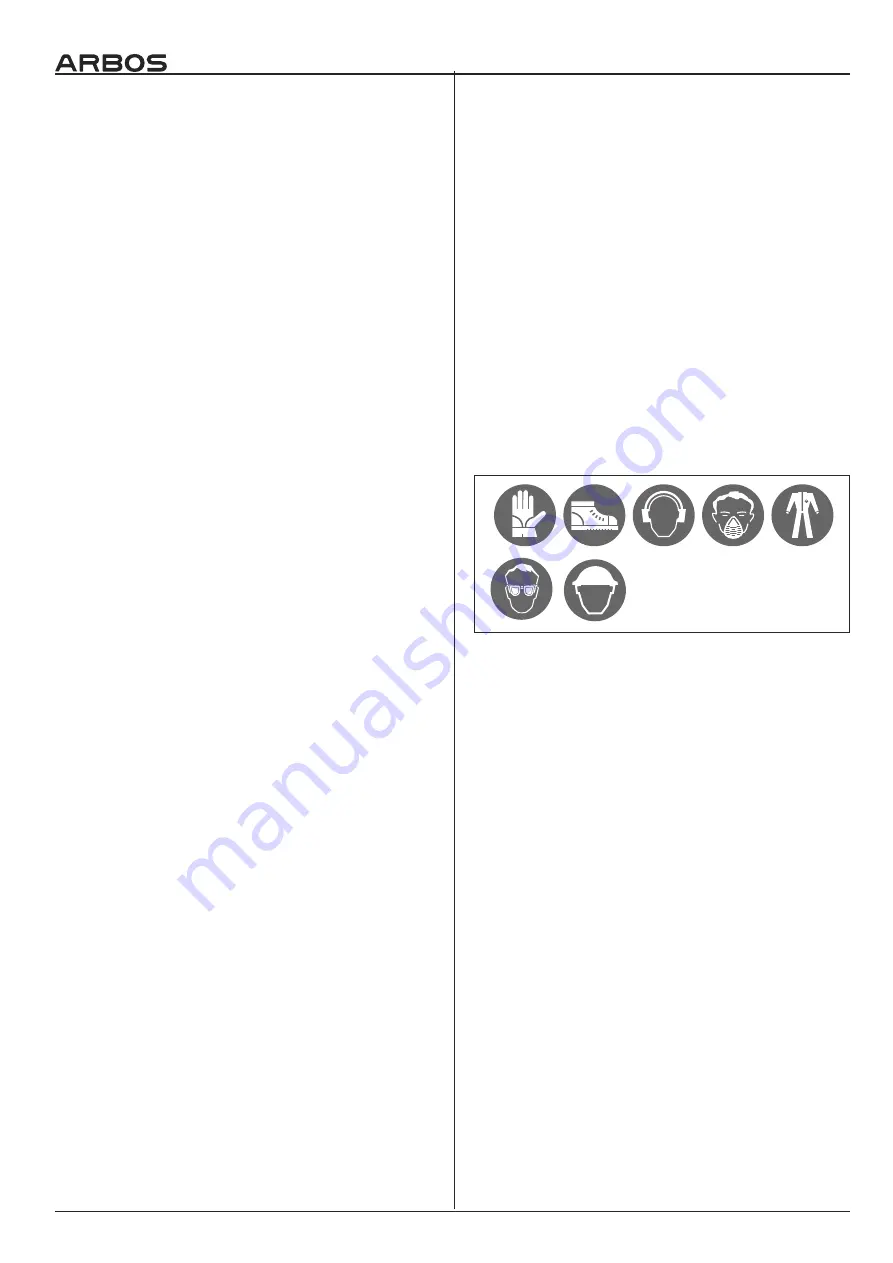

Personnel must use the safety provisions and personal

protection equipment when using or carrying out main-

tenance of the machine.

•

We recommend that operators of the machine do not

wear items of clothing which may become tangled in

the machine

Fig1.4

•

During use, the machine may emit dust. It is advised to

verify the filters on the cabin ventilation system periodi-

cally or use suitable protection systems for the respira-

tory tracts such as anti-dust masks.

•

During use, the operator must have sufficient visibility

on working areas considered as dangerous, therefore

the mirrors supplied on the tractor must be kept clean

and in a perfect state.

•

The machine must not be left unsupervised when the

tractor engine is on.

•

Keep the machine clean from foreign material (detritus,

tools, various objects), that could damage the functio-

ning or cause damage to the operator.

•

Avoid using it on muddy or soft ground.

•

Check the wear of the hydraulic tubes. Replace them if

deteriorated.

•

Do not use the controls or flexible tubes as handles; the-

se components are mobile and do not offer stable sup-

port.

•

Any modifications to the machine may raise safety con-

cerns. In such an instance, the operator will be wholly

responsible for any incidents.

Summary of Contents for Unica Super

Page 2: ......

Page 4: ...www matermacc it Use and maintenance handbook...

Page 16: ...www matermacc it Use and maintenance handbook Page 12...

Page 24: ...www matermacc it Use and maintenance handbook Page 20 F 5 Fig 4 14...

Page 34: ...www matermacc it Use and maintenance handbook Page 30...

Page 36: ......

Page 37: ...Use and maintenance handbook...