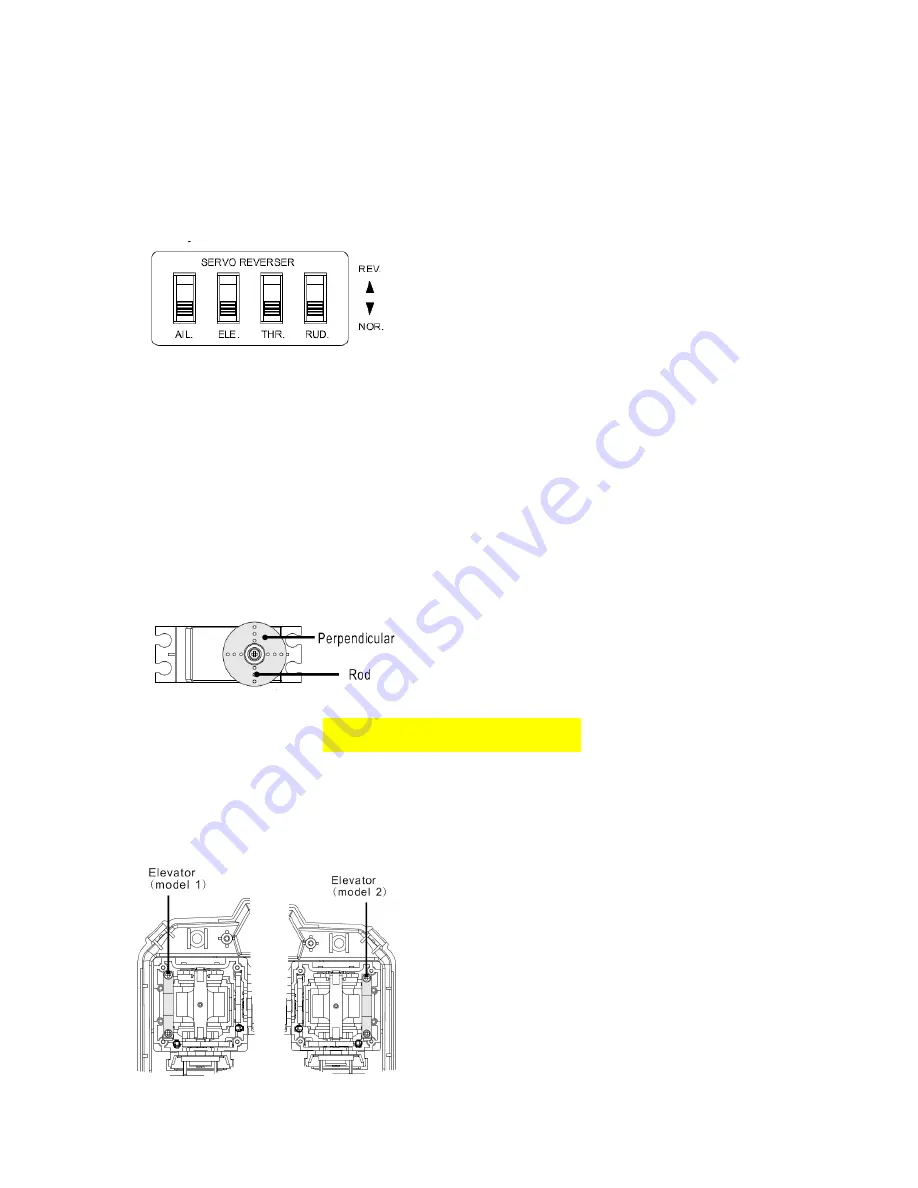

operates in the wrong direction, switch its

SERVO REVERSER switch (The direction of

operation can be changed without changing the

linkage).

Note that the direction of the aileron servo is

easily mistaken.

2. Neutral Adjustment: Check the aileron,

elevator and rudder neutral adjustment and

left-right (up-down) throw.

Check that when trimmed to the center, the

servo horn is perpendicular to the servo and

check the neutral position of the fuselage

control surfaces (aileron, elevator, rudder, etc.).

If the neutral position has changed, reset it by

adjusting the length of the rod with the linkage

rod adjuster.

When the throw is unsuitable (different from

steering angle specified by the kit instruction

manual), adjust it by changing the servo horn

and each control surface horn rod.

3. Check the engine throttle (speed adjustment)

linkage.

Change the servo horn installation position and

hole position so that the throttle is opened fully

when the throttle stick is set to HIGH (forward)

and is closed fully when the throttle stick and

throttle stick and throttle trim are set for

maximum slow (backward position and lower

position, respectively).

4. After all the linkages have been connected,

recheck the operating direction throw, etc.

Before flight, adjust the model in accordance

with the kit and engine instruction manuals.

5. Fly the model and trim each servo.

USING OTHER FUNCTIONS

LEVER SPRING TENSION ADJUSTMENT

The stick spring strength can be adjusted.

The operation feel of the throttle sticks can be

individually adjusted.

1. Remove the four transmitter rear case

screws and remove the rear case.

2. Adjust the spring strength by turning the

screw of the channel you want to adjust.

3. Close the rear case and tighten the four

screws.