24

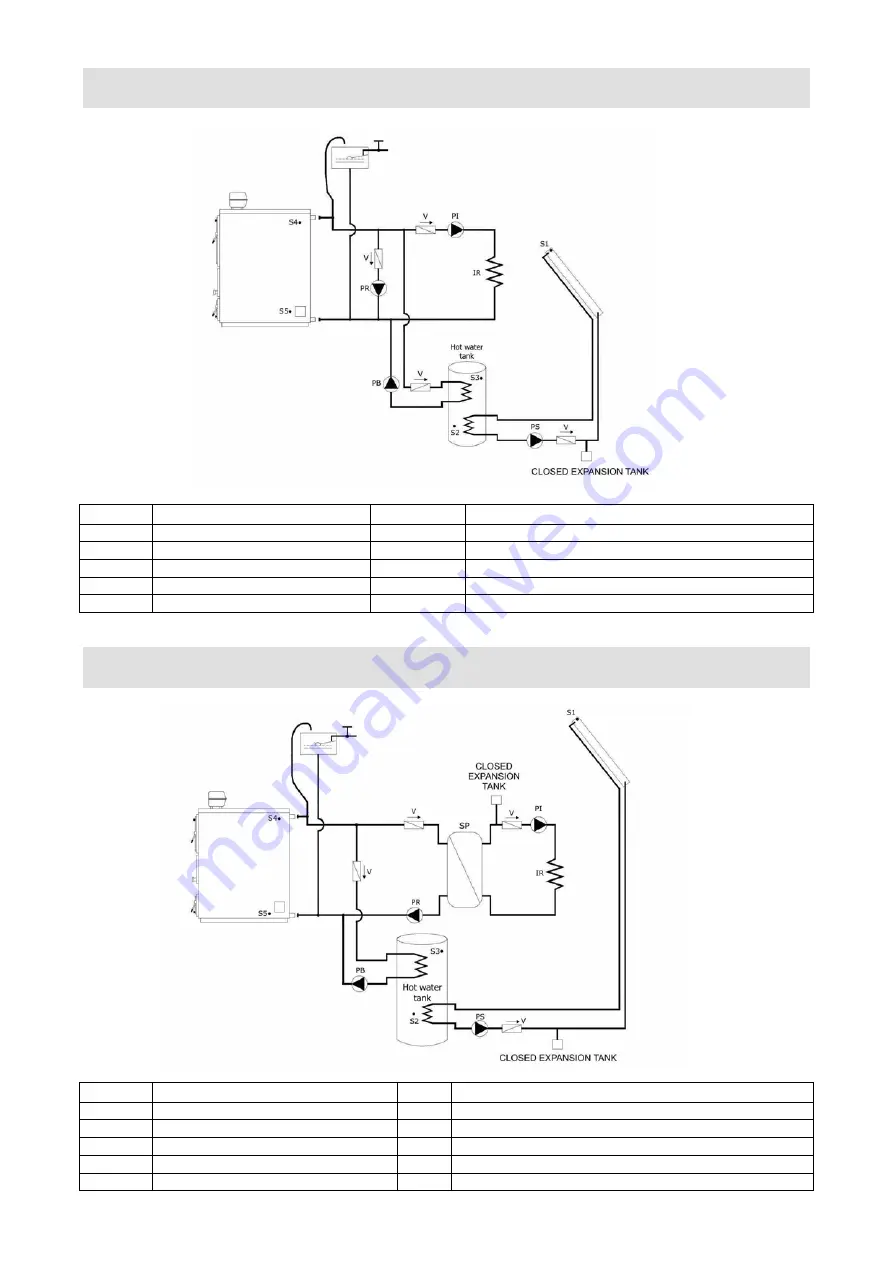

9.3.1. GENERAL CONNECTION DIAGRAM FOR A BOILER WITH EXTERNAL HOT

WATER PRODUCTION TANK AND SOLAR PANELS

Key:

PI

System pump

S1

Solar panel system probe

PR

Bypass pump

S2

Hot water tank probe - low point

PB

Hot water tank circuit pump

S3

Hot water tank probe - high point

PS

Solar panel system pump

S4

Heating system delivery temperature probe

IR

Heating system

S5

Heating system return temperature probe

V

Non return valve

9.3.2. GENERAL CONNECTION DIAGRAM FOR A BOILER WITH SOLAR PANELS AND

CLOSED

EXPANSION

TANK

Key:

PI

System pump

S1

Solar panel system probe

PR

Bypass pump

S2

Hot water tank probe - low point

PB

Hot water tank circuit pump

S3

Hot water tank probe - high point

PS

Solar panel system pump

S4

Heating system delivery temperature probe

IR

Heating system

S5

Heating system return temperature probe

V

Non return valve

SP

Plate heat exchanger