35

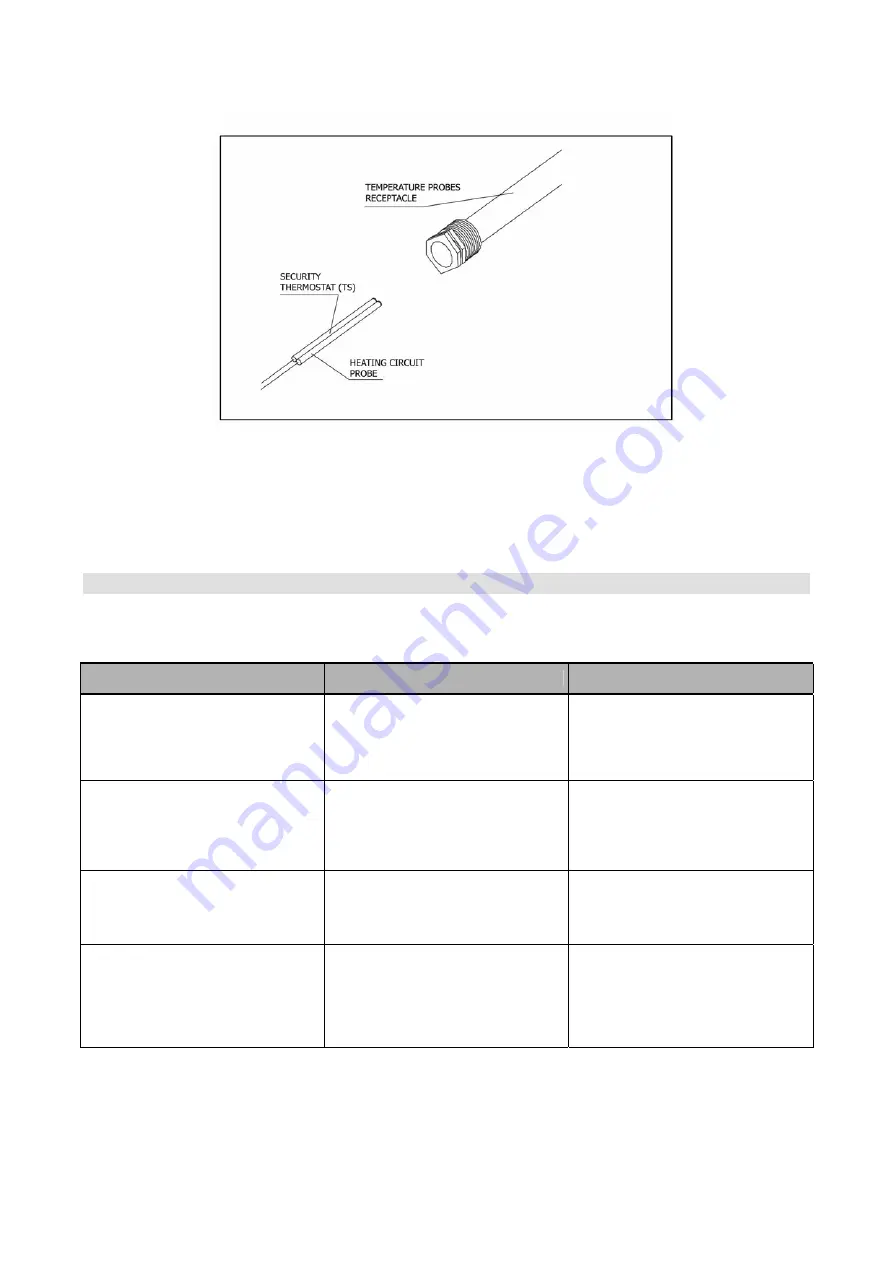

NOTE: both the security thermostat sensing element and the system delivery probe (S4) sensing bulbs must

be inserted together in the same receptacle near the heating system delivery connection.

Note:

In case problems occur during a probe installation, it is better to have the two terminals on the board for that

probe wire bridged to prevent the warning message of missing or faulty probe from being displayed.

Alternatively the problem may be fixed by pressing the button E for a long time until the programming mode

is entered and the missing probes can be disabled.

14.2. FIXING BOILER PROBLEMS

Symptoms

Possible causes

Solutions

The boiler tends to cut off leaving

an incurved wood mass unburnt in

the wood chamber. The restart is

abnormally long with a difficulty

flame formation.

a) The grate is plugged.

b) Not enough primary air

a) Unplug the grate slots

b) Increase the primary air

The flame is noisy and a lot of

white and black ash is produced.

The boiler features high fuel

consumption.

a) Too much primary air.

a) Decrease the primary air.

The flame is short, slow, the power

is abnormally low and the lower

door refractory plate is black.

a) Not enough primary air.

a) Increase the primary air.

The boiler produces a lot of liquid

tar in the wood chamber.

a) Too wet wood

b) Too low boiler temperature.

c) Long standby times with wood

chamber full of wood.

a) Load

dryer

wood

b) Rise the operation temperature

thermostat to 75 - 80°C

c) Proportion the total wood

quantity loaded to the real

needs.