15

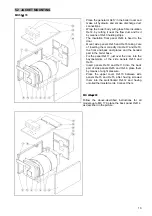

5.3 ANTICONDENSATION PUMP

In order to avoid system damages caused by unburnt gas condensation, it is necessary to insert a circulating

pump between the flow and the return.

The anti-condensation output can be calculated as follows:

−

1° method = boiler / 45 = l/h

−

2° method = water flow / 3 = l/h

The pump prevalence value will be the one indicated in the table about boiler specifications and, in particular,

about the water heat loss.

5.4 FLUE

The flue has an important role for the installation of a high efficiency boiler.

Low smoke temperatures and methane combustions require condensation proof flues. These flues have to be

highly insulated and corrosions proof.

On the market there are different companies which produce the kind of flues described and deliver flue

dimensions in accordance with local regulations.

6. USAGE

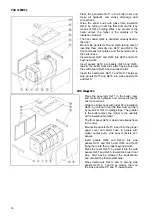

6.1 FIRST IGNITION CONTROL

At the first boiler and system ignition follow these instructions:

−

control the normal thermostat running;

−

control the correct placing of spiral coils up to the smoke combustion chamber;

−

control the boiler and flue connection tightness; take away all the possible openings by using glass fibre cord

resistant to high temperatures.

−

Control the front door tightness; in particular control there is no smoke coming out of the boiler and burner

connection.

−

Control the flue draught when the system is operating, control the flue depression.

−

Control the expansion vessel water level. The water level must respect foreseen levels. If steady water

adding are required, search for their cause, i.e. water losses, insufficient expansion vessel volume etc. A

steady water change can result in an easier boiler corrosion and calcareous deposit formation.

Similarly, control the closed expansion vessel efficiency. Control set values of safety valves and the automatic

alimentation group. Control the system is full of water and completely without air.

At first ignition verify:

−

pressure damper and safety valve set values;

−

the turning sense of the water cylinder circulating pump;

−

set values of the engine safety device as a protection of the water cylinder circulating pump.

6.2 RUNNING DATA

If the burner adjustment is good and using 3-5°E max. viscosity heavy oil at 50°C you will have the following

combustion data:

−

CO

2

12-14%,

−

smoke emissions have not to exceed the level 4 according to Bacharach' s scale,

−

smoke temperature at 200-220°C.

Using 1,4°E max. viscosity light oil at 20°C you will have the following data:

−

CO

2

11-13%,

−

smoke emissions have not to exceed the level 0-1 according to Bacharach' scale,

−

smoke temperature at 180-200°C.

Using methane:

−

CO

2

8-10,5%,

−

CO

< 0,1%,

−

smoke temperature at 160-200°C.

These values are possible if the boiler is clean and the water temperature at 80-90°C.

Summary of Contents for MK 100

Page 1: ...MK PRK Installation Usage Maintenance ...

Page 2: ......

Page 4: ......

Page 25: ...21 PRK ...