5-10

SET-UP AND SAFE OPERATING PROCEDURES

89210000

SECTION 5:

THE N6000 AUTOMATIC SYSTEM COMPONENT

DESCRIPTION

N6000 TORCH HEAD

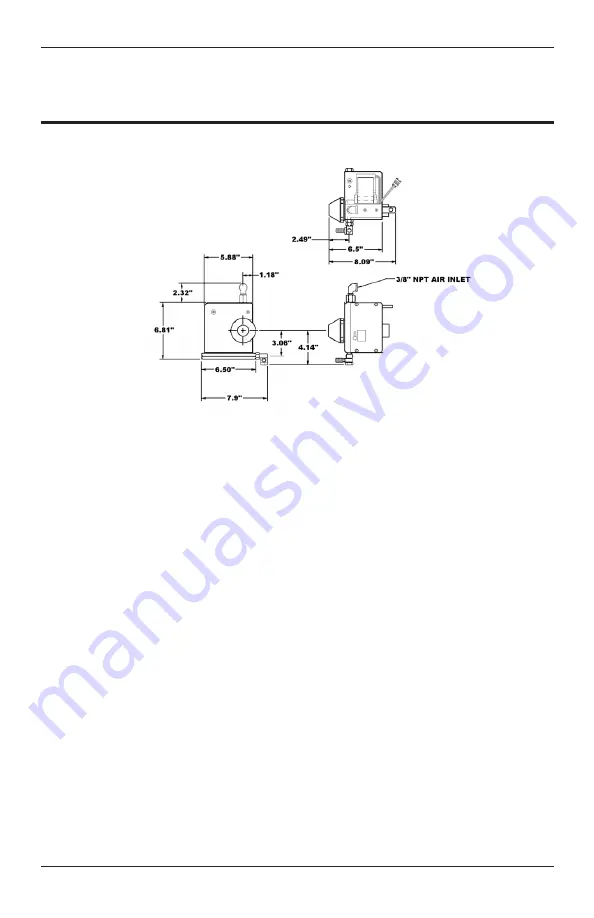

FIGURE 1 - N6000 Torch Head

The N6000 TORCH HEAD feeds the jointed electrodes down to the work surface. The Controller

controls and signals the motor on the Torch Head to feed or retract the electrode. This action

maintains arc voltage or current set on the Controller. Standard welding cables supply DC

current to the Torch Head. Compressed air coming from the Contactor connects at the Torch

Head with a 3/8” NPT female pipe elbow.

A Height & Angle Gauge, furnished with the Torch Head, sets the torch angle, electrode stick-

out, and correct air nozzle alignment. A protective cable boot (included) covers the power

connection on the buss bar.

The mounting bracket that comes with the Torch Head allows the Head to fasten to a travel

system or fixture. These brackets allow the head to be adjusted to the proper angle and

position for a particular application, then they can be tighten to hold the mounting position

(See Figure 1).

AUTOMATIC CONTROLLER

The AUTOMATIC CONTROLLER controls the system’s operation before, during and after gouging.

The following lists each of the panel’s control buttons and switches (left to right), and details

the function of each (See Figure 2)

The N6000 Automatic System