5-14

SET-UP AND SAFE OPERATING PROCEDURES

89210000

ELECTRODES

The most important part of the N6000 System is the electrode. Since the N6000 system uses

only DC power, the electrodes must be formulated and manufactured for use exclusively with

Direct Current.

The use of Arcair Jointed Jetrod Copperclad DC Electrodes is highly recommended. These

electrodes are manufactured to Arcair specifications to provide the best electrical conductivity, to

maintain proper electrode diameter at the point of the arc, and to minimize carbon sublimation.

A male/female joint enables electrodes to be joined together while the gouging operation is

taking place.

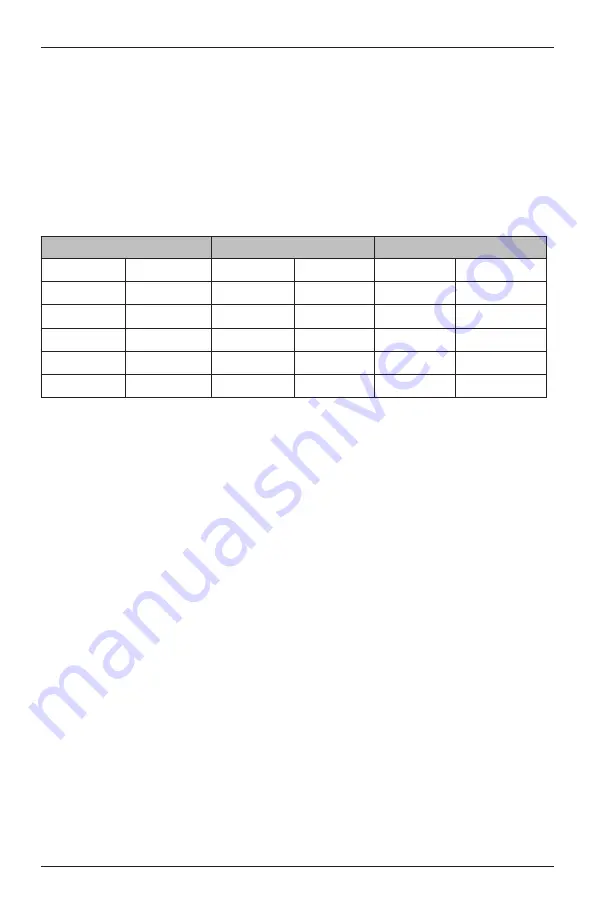

Electrode Side Diameter

Gouge Width

Amperage

Inches

mm

Inches

mm

Min

Max

5/16

7,9

7/16

11,1

400

450

3/8

9,5

1/2

12,7

450

600

1/2

12,7

13/16

20,7

800

1000

5/8

15,9

15/16

24,9

1000

1250

3/4

19,1

1-1/16

27,0

1250

1600

TABLE 1 ELECTRODE SELECTION

The formulation and design of the Jetrod electrodes embody numerous laboratory-proven

advantages under the user’s production conditions. Among these advantages are:

• Cooler operation due to a small incandescent area at the tip and joint.

• Excellent arc stability.

• High metal-removal rates.

• Uniformity of diameter.

• Clean grooves or cuts.

SELECTING THE PROPER ELECTRODE DIAMETER

Your choice should be based on the depth and width of the gouge you need. If you want a

gouge 1-1/2 times greater than the diameter of the electrode being used, make the groove in

two or more passes.

If you want a gouge wider than what is shown in Table 1, make the groove in two or more

passes or oscillate the Torch Head.

KEEPING ELECTRODES DRY

Keep electrodes dry. Damp electrodes should be dried before using. (Ten hours at 300°F

[176.7°C]) Wet electrodes may shatter from internal steam pressure when the arc is struck.

The N6000 Automatic System