SET-UP AND SAFE OPERATING PROCEDURES

8-29

89210000

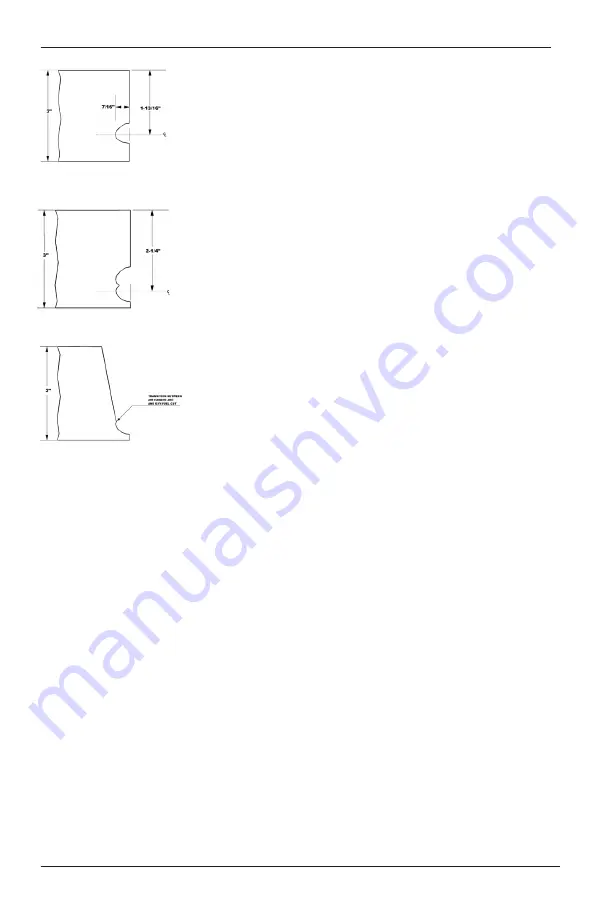

FIRST STEP: Make a U-groove with a 3/4” electrode, 7/16” (1.11

cm) deep. Location of electrode from the top surface should be

1-13/16” (4.60 cm).

SECOND STEP: Relocate the electrode 2-1/4” (5.72 cm) from the

top surface and make the gouge.

THIRD STEP: Flame cut 10° bevel to the bottom of the first

gouge.

FIGURE 11 - J-GROOVE WELD PREPARATION FOR MATERIAL THICKNESS OVER 2” (5.08 CM)

ZERO FORCE ROUGH MACHINING

The N6000 system can work with an automated travel system to remove hardsurfacing

material from steel mill rolls; kiln rolls and shafts which needs re-working. Remove as much

as 1-1/2” of old material from the outside diameter in a single pass and as little as 1/8” for

the finish pass.

OSCILLATION GOUGING TO REMOVE MATERIAL UP TO 4” WIDE

The N6000 can be mounted on a welding oscillator to remove material in widths up to 4 inches.

Normal uses for an oscillated gouge would be to remove cladded material from plates requiring

a beveled edge and to remove backup bars and excessive weld crowns.

REMOVING FILLET WELDS AND OUT-OF-POSITION U-GROOVE WELD

PREPARATIONS

The torch head of the N6000 system can be mounted on tractors that do out-of-position work

whether the work is overhead, around the outside circumference of a pipe, or on the inside

of a large vessel.

Uses of the N6000 System