XL3000

2 rev.

121218

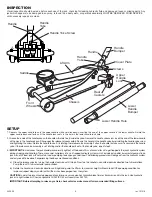

INSPECTION

Visual inspection should be made before each use of the jack, checking for leaking hydraulic fluid and damaged, loose or missing parts. Any

jack which appears to be damaged in any way, is found to be badly worn, or operates abnormally MUST BE REMOVED FROM SERVICE

until necessary repairs are made.

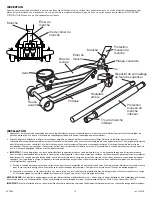

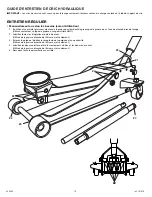

SETUP

1.

Depress the upper handle lock in the upper handle while simultaneously inserting the end of the upper handle in the lower handle. Rotate the

upper handle back and forth until the handle lock seats in the hole in the lower handle lock hole

.

2. Grease the inside of the handle yoke so the handle will rotate freely inside the yoke. Remove the handle yoke screw. Insert the end of the lower handle

all the way in the handle yoke until it engages the release valve assembly. Secure the handle in the handle yoke by reinstalling the handle yoke screw

and tightening the screw. Rotate the handle to see if it is rotating the release valve assembly. Pull on the handle to make sure it is secured in the handle

yoke. If the release valve assembly is not rotating and/or the handle pulls out of the handle yoke, repeat step 2.

3. I

MPORTANT:

In most cases the jack should work normally right out of the box but it is not unusual for air to get trapped in the jack’s hydraulic system

during shipping and handling. There are several symptoms of an air trapped hydraulic system which include only partial incremental pump stroke,

jack will not lift load, jack will not sustain load or pumping feels spongy under load. The following procedure will purge air from the hydraulic system

and only needs to be done if experiencing the above mentioned conditions.

a) Close the release valve by turning the handle clockwise until it stops. Now turn the handle in a counterclockwise direction two full revolutions.

Pump the jack 10 full incremental pump strokes.

b) Rotate the handle in a clockwise direction until tight and pump the lift arm to maximum height without a load. If the pumping condition has

improved, repeat steps a) and b) until all the air has been purged from the system.

CAUTION:

In order to prevent seal damage and jack failure, never use alcohol, hydraulic brake fluid, or transmission oil in the jack. Use hydraulic

jack oil, a light turbine oil, Chevron Hydraulic Oil AW ISO 32 or Unocal Unax AW 150.

IMPORTANT: Before attempting to raise any vehicle, check vehicle service manual for recommended lifting surfaces.

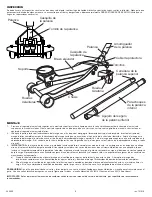

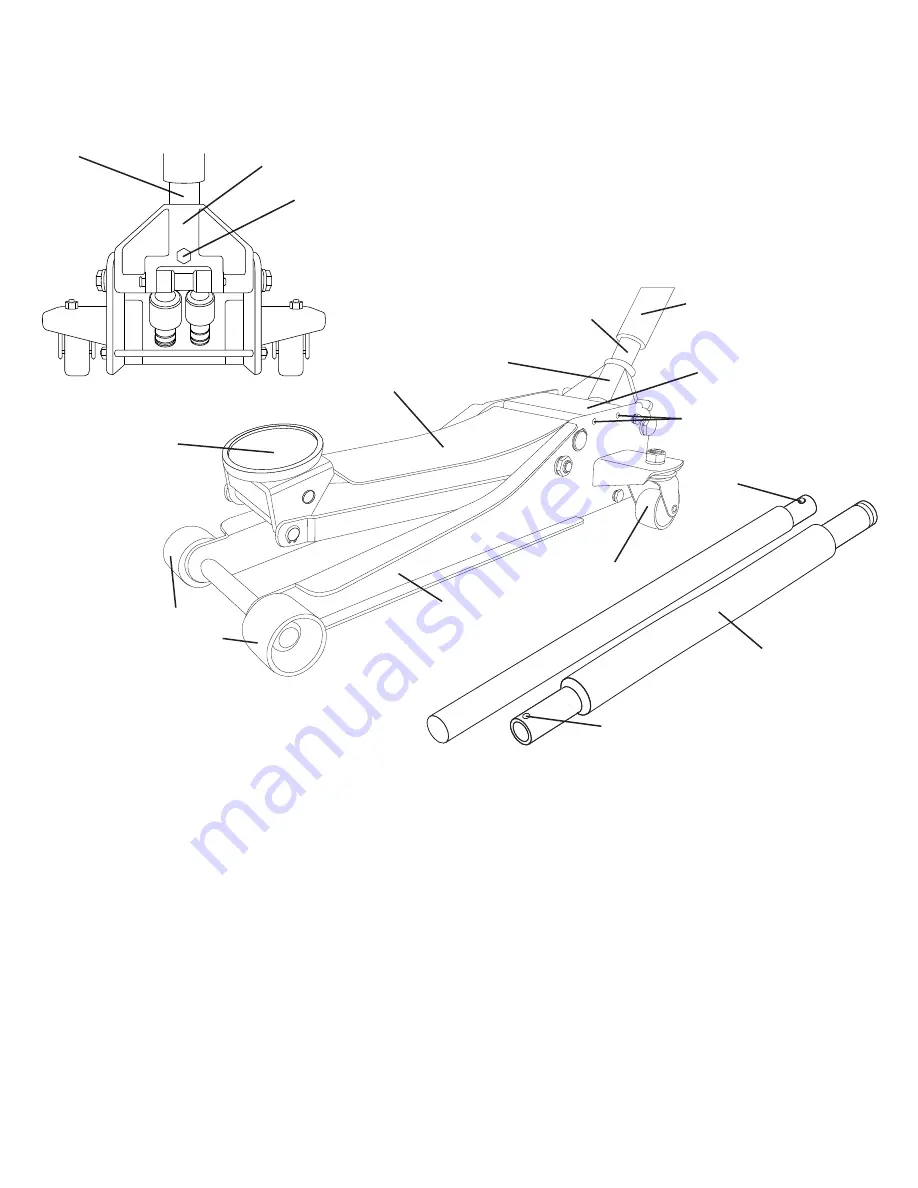

Handle Yoke Screw

Handle

Handle

Yoke

Upper

Handle

Lock

Lower

Handle

Bumper

Lower Handle Hole

Saddle

Chassis

Lift Arm

Handle

Bumper

Handle

Yoke

Handle

Cover Plate

Screws

Rear

Casters

Front

Wheels