PAPR

-8-

Filter Installation:

1. Open the filter cover (Fig. 4).

2. Remove the old filter (if installed) with a slight twisting motion as you pull it away from blower.

3. Install the new filter onto the blower using the same rotating motion as you push (Fig. 5).

4. Close the filter cover onto the blower, making sure the right tab snaps onto the blower.

5. Check that the filter cover is secured.

2.4 Blower

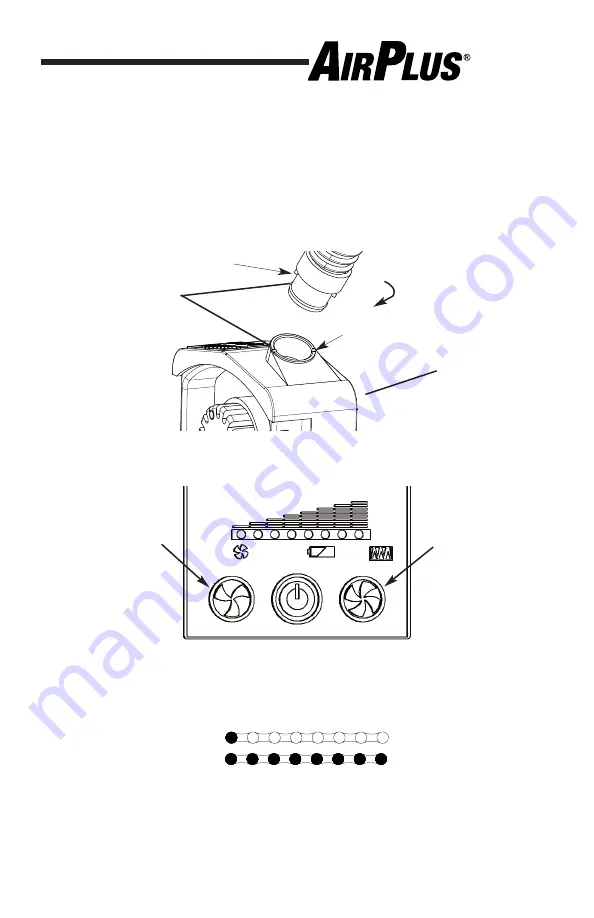

1. Install the Breathing Tube into the Blower as shown (Fig. 6).

2. Operate the Blower (Fig. 7).

Become familiar with the operation of your

A

RC

O

NE

®

A

IR

P

LUS

®

PAPR

system blower unit before

initial operation. The controls operate as follows:

Power Button - turn the blower unit on or off.

High Speed Fan - increase airflow indicated by GREEN LED panel above power button.

Low Speed Fan - decrease airflow indicated by GREEN LED panel above power button.

Filter/Airflow status indicated with GREEN LEDs.

Filter/Airflow status: GOOD.

Filter/Airflow status: Near Full.

Battery: When blower is turned on the LEDs will flash RED. (ALWAYS begin each shift with a

fully charged battery.)

Audible Alarm: Airflow blocked/change Filter soon.

Audible Alarm plus Vibration: Airflow blocked/Replace Filter.

Audible Alarm (short beep) & RED LEDs flash: RECHARGE BATTERY.

PD F created w ith pdfFactory t

rial version

www.pdffactory.com

Figure 6

Breathing Tube

Insert

Turn to Lock after Inserting

into Blower Connector

Blower

Align Pin into Slot on

Blower Connector

Fan (High Speed)

Figure 7

Fan (Low Speed)

AIR

BATTERY

FILTER

Power Button