2.

Faulty components in the unit, return for repair or have authorised technician repair.

B. Low cutting output

1.

Incorrect setting of cutting current (A), check and adjust to correct setting.

2.

Faulty components in unit, return for repair or have authorised technician repair.

C. Torch can cut but the cutting quality is poor

1.

Current (A) control set too low, increase current setting.

2.

The torch moves too fast across the workpiece, reduce cutting speed.

3.

Excessive oil or moisture in torch, hold torch 1/8 inch (3 mm) from clean surface while purging and

observe oil or moisture buildup (do not activate torch). If there are contaminants in the air additional

filtering may be needed.

4.

Lack of air pressure. Please check the air pressure and air flow, adjusting it to the correct pressure.

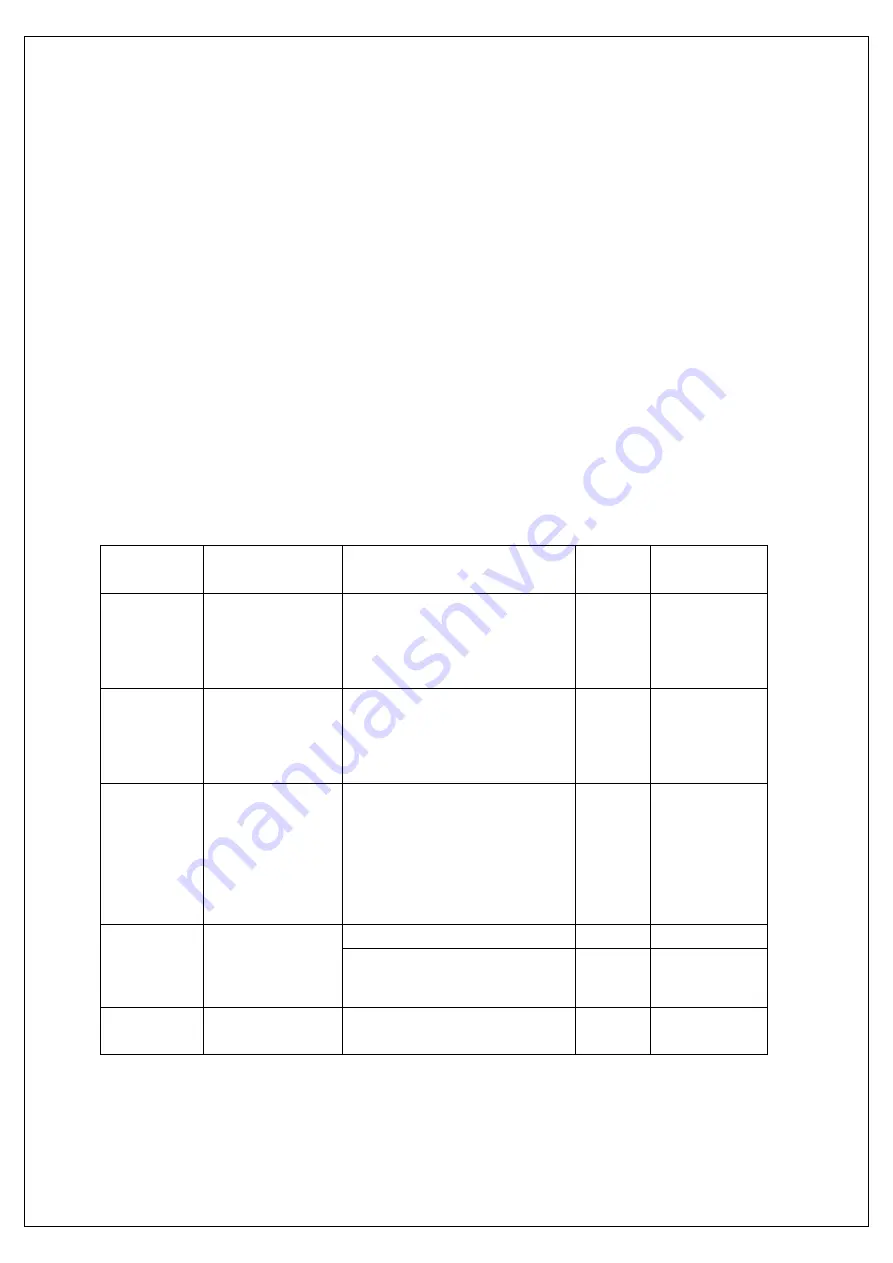

5.2 Mainframe and Selectable Packing

Chart 5.1 list

Serial number

Accessories name

Specifications and Models

Quantity

mountings code

1

Mainframe

ArcoCut 100i cutting power(3-380V)

3.008.662

2

Cutting torch and

Accessories

ST-120 non-HF Arc starter cutting gun

1

7.603.040

3

Earth cable

10mm2 ,4m

One small quick plug

One 300A earth clamp

1

6.310.322-B

4

Air

channel

accessories

Air tube

Φ

12

4

7.501.018

tube hoop

2

7.514.007

5

Specification

ArcoCut 100i

1

8.850.148

14

Summary of Contents for ARCOCUT G-100i

Page 1: ......