6

faster troubleshooting, eliminating unnecessary downtime.

7.

Back striking tip and electrode ensure the speed of striking and the quality of the arc, and therefore

extend the life of the consumables.

3 Installation

3.1 Unpacking

Use the packing lists to identify and account for each item.

1.

Inspect each item for possible shipping damage. If damage is evident, contact your distributor and / or

shipping company before proceeding with the installation.

2.

When using forklift, ensure to lift safely and with due care to support entire unit.

3.

Unplanned movement may cause potential danger or hazards, so please make sure that the machine

is in a safe position before utilisation.

3.2 Input Power Connections

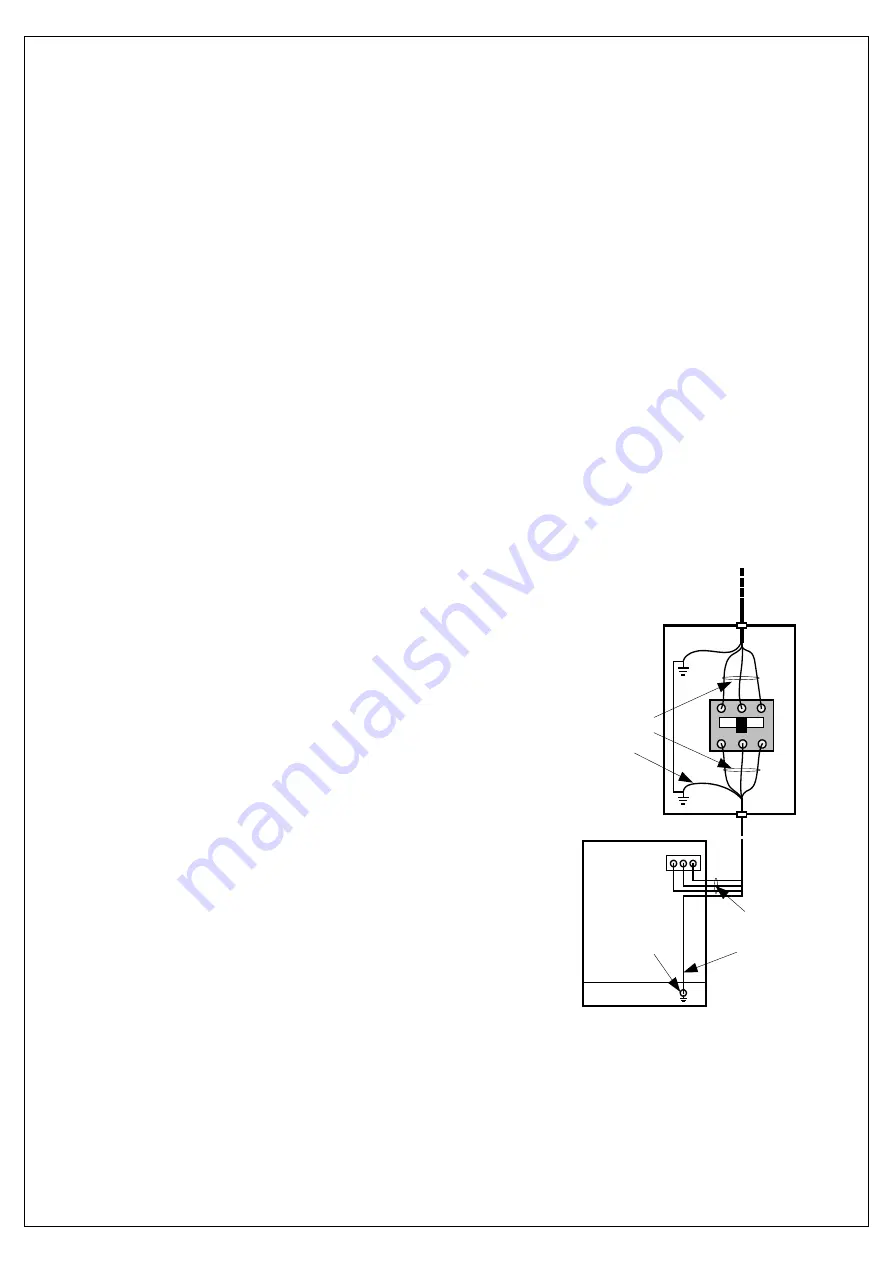

Supply input connection of ArcoCut 100i power is shown as

the Fig3.1.

1.

Check your power source for correct voltage before plugging in or

connecting the unit

2.

Power Cord and Plug -This power supply includes an input power

cord and plug suitable for 3 phase power connection.

3. If the power supply voltage continually goes beyond the

range of safe work voltage range, it will shorten the unit’s

lifespan. The following measures can be used:

Ensure correct supply input.

Utilise the machine within its correct operating

parameters.

Set the voltage stabilization device in the front of power cable

input.

3.3 Air Connections

1.

Connecting Air Supply to Unit

Connect the airline to the inlet port of the air filter on the rear panel.

2.

Check Air Quality

To test the quality of air, put the RUN / SET switch in the SET (down) position, check if there are is oil

or moisture in the air.

Live wire

Earth wire

3

~

380V

Power

cable

Rear panel

Distrubutor

Earth wire

Live wire

Power

input

Power

switch

Power

cable input

Fig 3.1 the connect method of

the main supply

Summary of Contents for ARCOCUT G-100i

Page 1: ......