29

insulation is thought to be damaged and needs to be changed.

5.2 Troubleshooting

Before arc welding machines are dispatched from the factory, they have already been debugged accurately.

Maintenance must be performed carefully. If any wire becomes flexible or is misplaced, it may be a potential

danger to user!

Only Professional maintenance personal who are Authorized by Arcoweld can overhaul or repair the machine.

Always turn off the power source before removing covers or working on unit.

If there are any problems, please contact your authorized repairer or distributor.

If there are any issues with the welding machine, please consult the following trouble shooting chart:

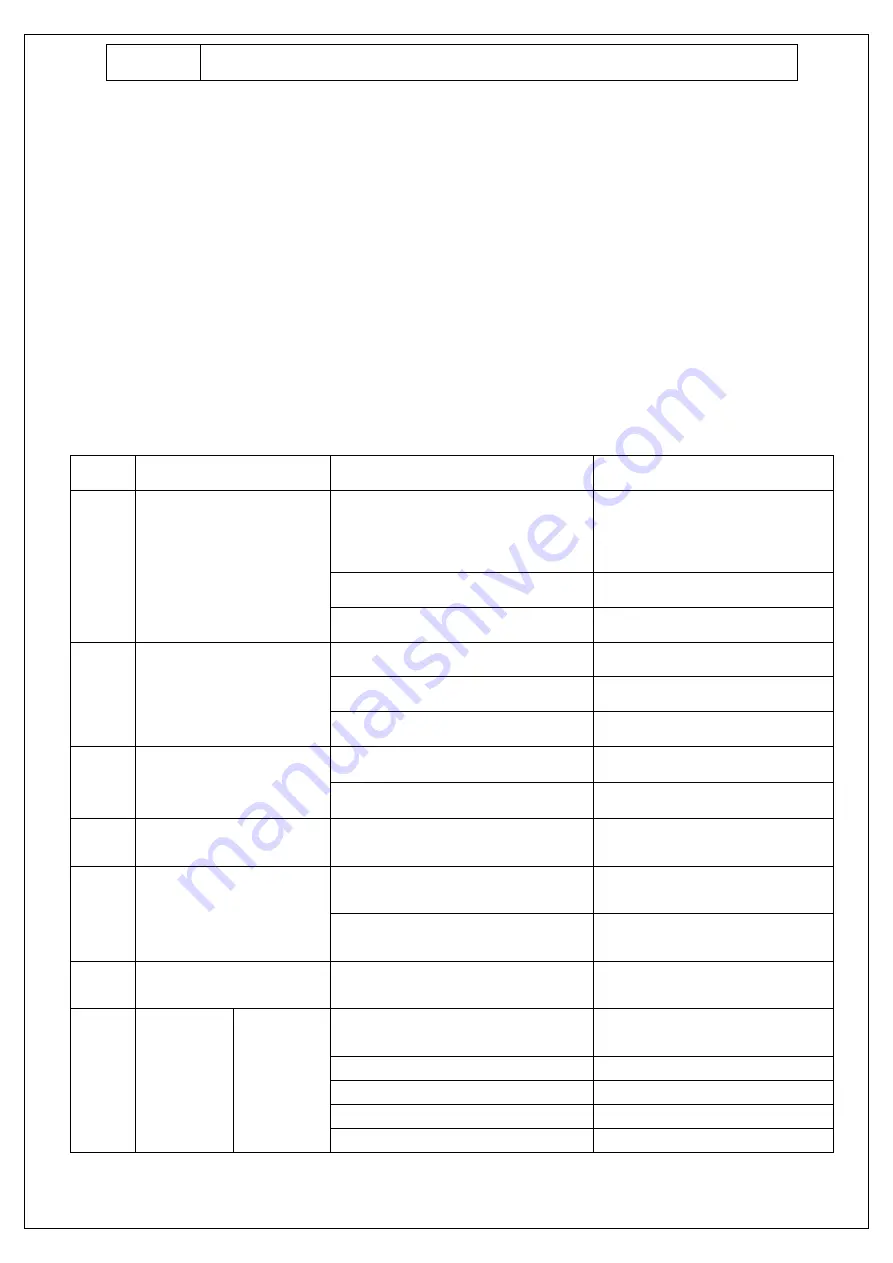

S/N

Issue

Reasons

Solution

1

Turning on the power source,

and fan works, but the power

pilot lamp is not on.

The power light is damaged, or connection is

not good

Check and repair Pr7

The transformer of power is broken

Repair or change the transformer

Control PCB failures

Repair or change the control Pr4

2

Turning on the power source,

and the power lamp is on, but

fan doesn’t work

There is something in the fan

Clear out

The start capacitor of fan damaged

Change capacitor

The fan motor is damaged

Change fan

3

Turning on the power source,

the power lamp is not on, and

fan doesn’t work

No power supply input

Check whether there is power supply

The fuse inside the machine damaged

Change it (10A)

4

The number on the display is not

intact.

The LED in the display is broken

Change the LED

5

The max and min value displayed

doesn’t accord with the set

value.

The max value is not accordant (refer to 3.1)

Adjust potentiometer Imin on the power

board.

The min value is not accordant (refer to 3.1)

Adjust potentiometer Imaxin the current

meter.

6

No no-load voltage output

(MMA)

The machine is damaged

Check the main circuit and the Pr4.

7

Arc can not be

ignited (TIG)

There is spark

on the HF

igniting board.

The welding cable is not connected with the

two output of the welder.

Connect the welding cable to the

welder’s output.

The welding cable damaged.

Repair or change it.

The earth cable connected unstably.

Check the earth cable.

The welding cable is too long.

Use an appropriate welding cable.

There is oil or dust on the workpiece.

Check and remove it.