Model 20702 Page 6

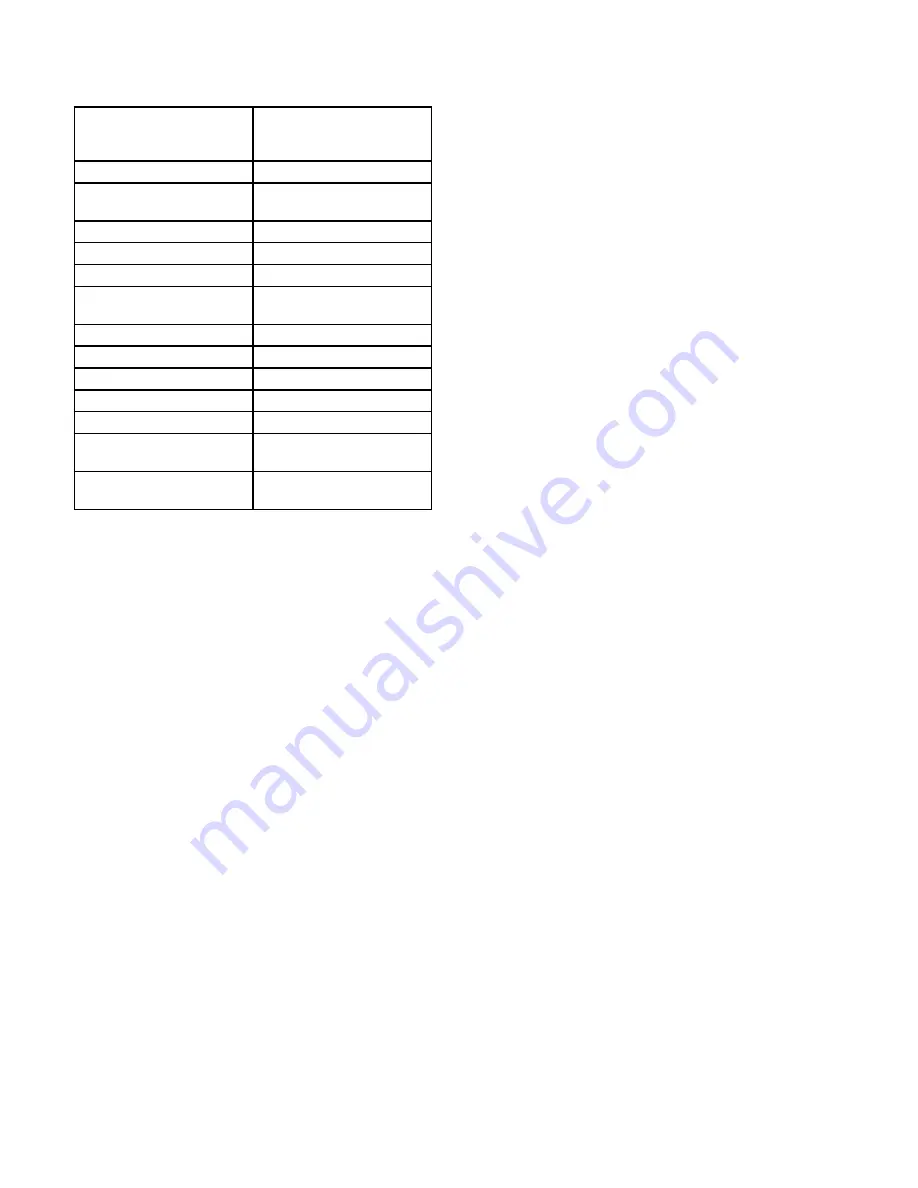

Power Source

Solar Powered Cells with

non-replacable back up

battery

Power ON/OFF

Fully Automatic

Lens Type

ANSI Z87.1-2010 ap-

proved

Viewing Field

3.86” x 1.61”

Cartridge Size

4.33” x 3.54” x 0.35”

Light Shade State

Shade DIN 4

Darkened Shade State

Shade DIN 9 to DIN 13

Variable

UV/IR Protection*

Permanent Shade DIN 16

Sensors

Two

Grinding Shade State

Shade DIN 4

Sensitivity Control

High/Low Switch

Reaction Time

1/10,000 second

Operational Temperature

23 degrees F to 131 de-

grees F

Storage Temperature

-4 degrees F to 158 de-

grees F

Cartridge Specifications

*UV/IR auto-darkening filters provide full protec

-

tion to eyes/face during the welding procedure,

even when in clear state (UV/IR protection is

shade DIN 16 all the time).

Maintaining the Welding Helmet

1. Clean the Front and Inside Cover Lens

with a dry lint-free cloth or tissue. Never

immerse the Cover Lens in water and do

not use solvents or abrasive products in the

cleaning process.

2. Keep the Welding Helmet clean by using

a mild soap and damp cloth. After cleaning,

dry the helmet with a clean cloth.

3. Replace the Front Cover Lens when it

becomes cracked, scratched or damaged in

any other way.

To replace the Lens: Lift up on tab at bottom

of Frame and pull out the Lens.

Remove protective film on the new Lens.

Put the new Lens into place and snap Front

Frame to secure Lens into position.

4. The Cartridge is not replaceable. Do not

attempt to open or remove this Cartridge

from the Helmet.

Troubleshooting

1.

Unclear vision.

To correct, clean Front

and Inside Cover Lens and clean Cartridge.

Made sure shade number selected is correct

for the application. Made sure surrounding

light in the workplace is adequate.

2.

Inconsistant Darkening

. Headband

may need adjusting. Made sure Headband

positions Lens so that it is equal distance

from left and right eye.

3.

Cartridge Does Not Darken

. If the Auto-

Darkening Cartridge does not darken, or

has a fluttering image, the front Cover Lens

should be cleaned along with the sensors

in the Cartridge (clean surface of sensors).

Use a soft clean cloth to clean.

This problem could also be caused by too

low of a weld current. Correct by switching

the Lens Sensitivity Control on the inside of

Helmet to “LOW”.

4.

Too Slow Response Time

. Never use

Welding Helmet in temperatures below 23

degrees Fahrenheit. When the Welding

Helmet is stored in very cold temperatures,

warm the Helmet to ambiant temperature

before using.

Limited Warranty

ArcPro warrants to the original retail purchaser

that the product is free of defects in material

and workmanship at the time of shipment. This

Welding Helmet is warranteed for 90 days from

the date of purchase. This warranty is expressly

in lieu of all other warranties, express or implied.

Proof of purchase is required for warranty trans-

actions; a copy of the original invoice or sales

receipt is required.