Instruction manual – AQ 110 arc protection unit

41 (80

)

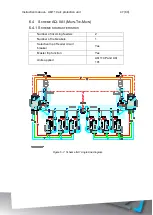

AQ101 (all units):

I/O

Function

S1

Monitoring of arc light in outgoing feeder cable

compartment for selective trip (Zone 3)

S2

Monitoring of arc light in outgoing feeder breaker

compartment and busbar compartment (Zone 2) (*)

BO1

Sending light information to AQ 110 unit of incoming

feeder 1

BI1

Receiving overcurrent information from AQ 110 unit of

incoming feeder 1

BI2

Receiving master trip information from AQ 110 unit of

incoming feeder 1

T1

Trip of outgoing feeder circuit breaker CB4-x in case of

activation of S1 and BI1. Also performing master trip in

case of fault in Zone 2.

T2

Not in use

T3

Not in use

T4

Not in use

SF

System failure dry contact for alarming

*Sensor channels S3, S4 and S5 may be utilized if more sensors are required

in Zone 2

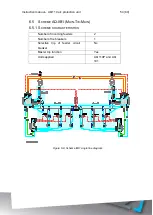

6.2.3

T

RIP LOGIC

,

CONNECTION DIAGRAM AND DIPSWITCH

SETTINGS

CB1

CB2

CB4-x

Zone 1

x

x

Zone 2

x

x (MT)

Zone 3

x

CBFP of CB1

x

CBFP of CB4-x

x

AQ 110

T1

T2

AQ 101A-x

T1

Table 6-2: Scheme IA1 trip logic