This type of application normally uses an auto-recloser with two shots (one high-speed and one

delayed) which are triggered by earth fault protection or overcurrent protection. Short-circuit protection

is used for interlocking the auto-recloser in case a clear short-circuit fault occurs in the line.

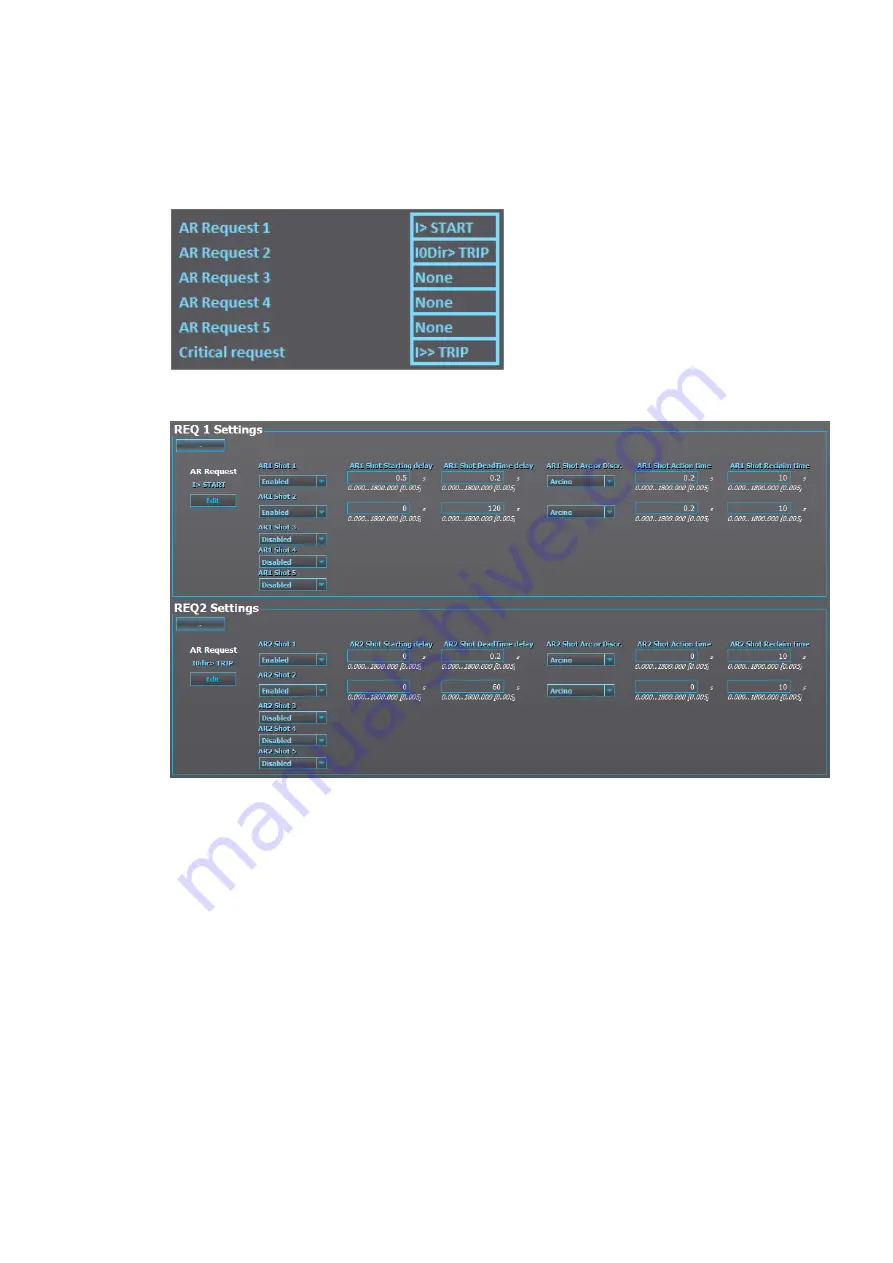

Figure. 5.4.4 - 188. Example of assigning request signals.

Figure. 5.4.4 - 189. Example of shot settings (two requests and two initialized shots).

In this example, earth fault (REQ2) uses its own operating time settings, whereas the time delay for

overcurrent (REQ1) comes from the auto-recloser's own settings. Both fault types can initialize both of

the shots with different settings. If the fault evolves from earth fault into a multi-phase fault, the auto-

recloser uses the AR1 settings for the reclosing. In this example, the dead time between the first and

the second shot in REQ1 differs from the dead time in REQ2 because the air needs more time to cool

and de-ionize after an overcurrent or a multi-phase fault than it does after an earth fault. If the high-set

overcurrent stage activates in any situation, the auto-reclosing sequence is stopped, the final trip is

issued and the feeder closing is locked by the auto-recloser. A manual reset of the auto-recloser's lock

is required before one can attempt to close the breaker. A manual reset can be applied from SCADA or

locally from the relay's HMI.

Based on the example above, the following six (6) sections present the principle signaling of the auto-

recloser function. These are the auto-recloser sequence variations that can occur with this setup:

• from Trip with two shots (both fail)

• from Trip with two shots (high-speed fails, time-delayed succeeds)

• from Trip with two shots (high-speed succeeds)

• from Start with two shots (both fail)

• from Start with two shots (high-speed fails, time-delayed succeeds)

• from Start with two shots (high-speed succeeds).

A

AQ

Q-F215

-F215

Instruction manual

Version: 2.04

305