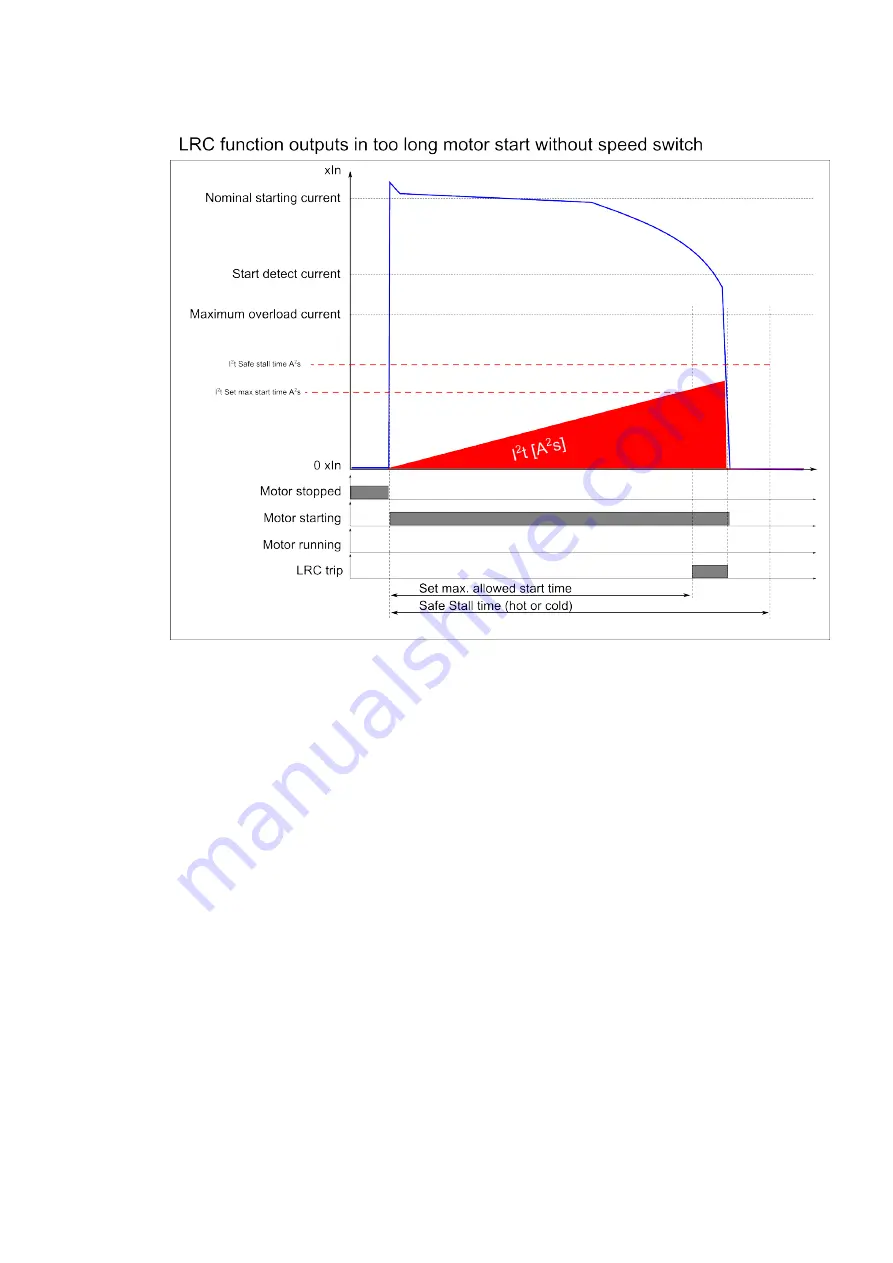

Figure. 5.3.9 - 103. Outputs when motor starting takes too long, no speed switch.

There are many reasons why the motor starting takes too long. These include problems in the drive or

in the application. There may also be an issue with the feeding network: if the started motor is very

large and the feeding network is weak, its voltage may drop and therefore the motor cannot provide the

needed torque for normal starting, resulting in a prolonged start-up situation. This is why the I

2

t mode

is suggested as it can compensate for the voltage drop by taking the lower starting current caused by

the lower voltage into account. If definite time is preferred for the Ist> function, it may cause a situation

where the starting is well in action but the user-allowed time is spent due to the lower current and lower

torque caused by the network's low voltage. In this case the function may trip before the starting is over

eventhough the motor is not yet stressed too much and could still continue the starting.

A speed switch –if available in the application– activates when the motor shaft rotates or accelerates,

and it can be used to give the motor additional time for starting beyond the set maximum starting

duration. If the speed switch is in use while a similar situation happens (that is, that the motor starting is

taking longer than it should), the speed switch ensures that the start-up of the motor is still going

fine and the function lets the starting process continue.

A

AQ

Q-M210

-M210

Instruction manual

Version: 2.04

136