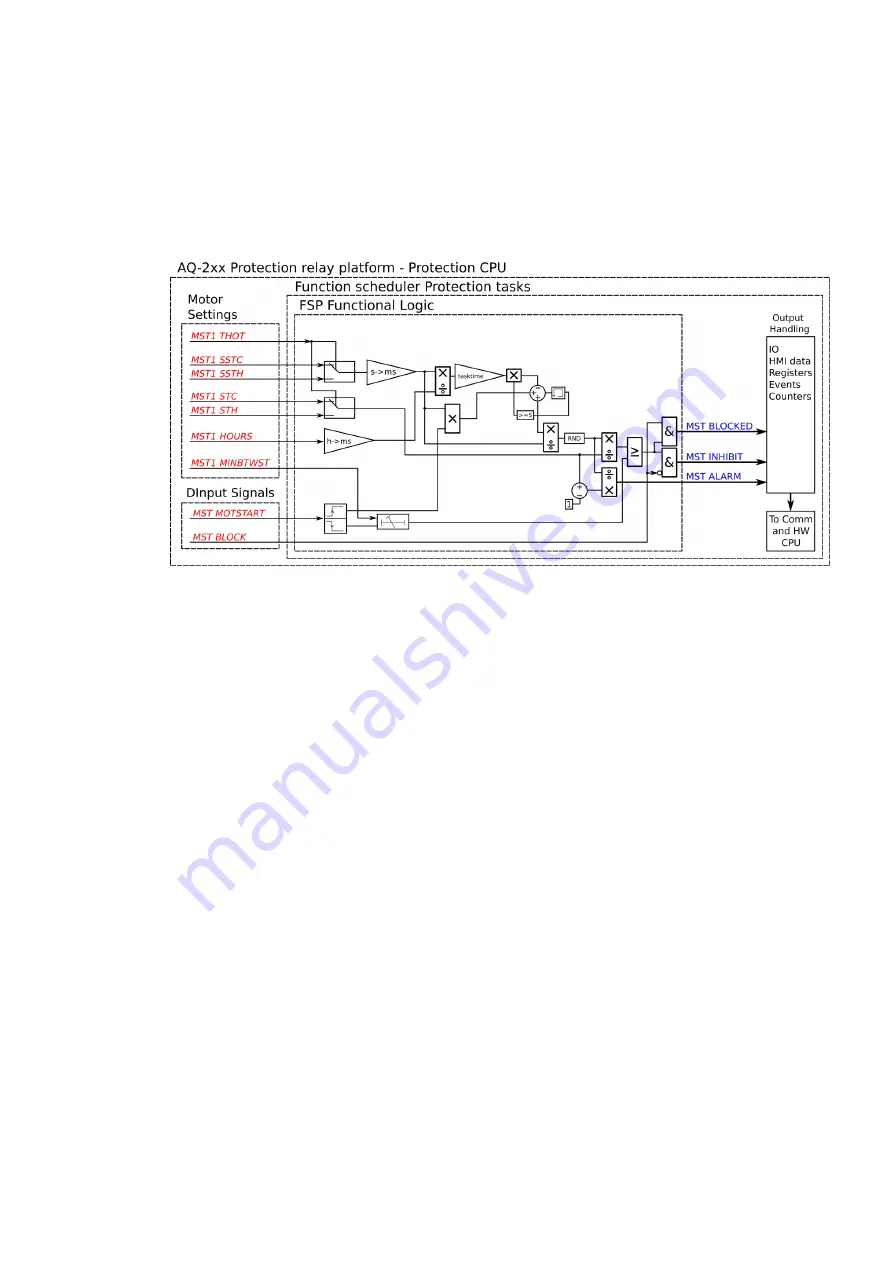

The frequent start protection function in a motor protection module operates with the motor status

monitoring function and follows the motor data set there. Motor starting is monitored internally (MST

signal out) in the N> function. The user only needs to activate the N> function and then do the

following: set the number of allowed starts for hot and cold situations, set the minimum time between

consequent starts, and set the limits of "Hot" and "Cold" situations. The thermal overload function also

needs to be activated and set, if the user wants to use the hot and cold motor status separation.

Figure. 5.3.21 - 160. Simplified function block diagram of the N> function.

The operating principle of the frequent start protection function is to calculate an equivalent start

stress in each start; the calculation is based on the set starts per hour and the safe stall time settings

(hot and cold) regardless of the actual start duration. In each start attempt the function does the

following calculation: a time equal to the safe stall time and is added to the starts counter, and the

quotient of the safe stall time divided by the set starts time (in hours) is then subtracted from this sum.

This way the start counter can be applied to follow the motor's thermal status and the number of starts

per hour accurately.

A

AQ

Q-M215

-M215

Instruction manual

Version: 2.04

235