Setting up the activation and release delays

The settings described in the table below can be found at

Control

→

Device I/O

→

Digital input

settings in the relay settings.

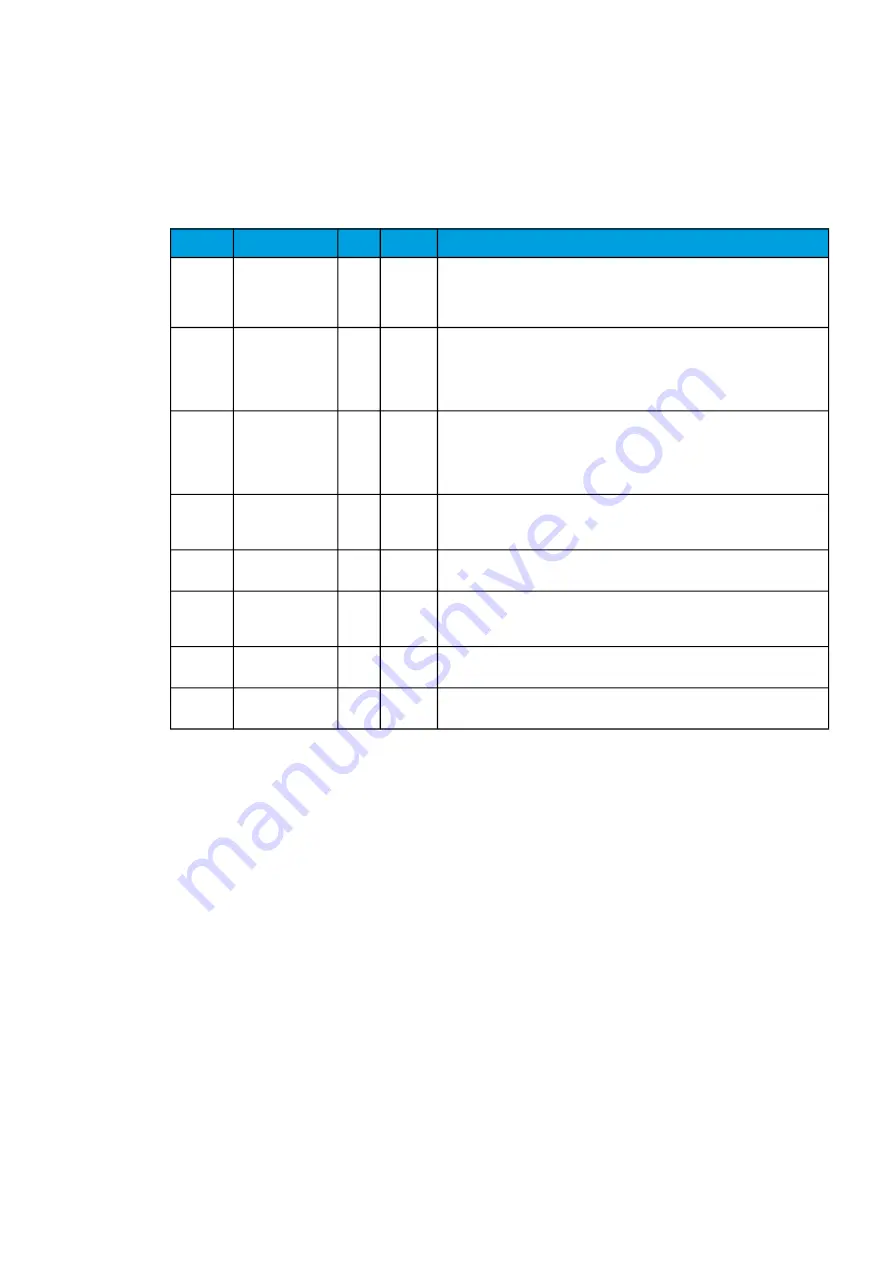

Table. 8.5 - 285. Digital input settings of DI8 module.

Name

Range

Step Default

Description

DIx

Polarity

0: NO (Normally

open)

1: NC (Normally

closed)

-

0: NO

Selects whether the status of the digital input is 1 or 0 when the input is

energized.

DIx

Activation

threshold

16.0…200.0 V

0.1 V

88 V

Defines the activation threshold for the digital input.

When "NO" is the selected polarity, the measured voltage exceeding this

setting activates the input. When "NC" is the selected polarity,

the measured voltage exceeding this setting deactivates the input.

DIx

Release

threshold

10.0…200.0 V

0.1 V

60V

Defines the release threshold for the digital input.

When "NO" is the selected polarity, the measured voltage below this

setting deactivates the input. When "NC" is the selected polarity,

the measured voltage below this setting activates the input.

DIx

Activation

delay

0.000…1800.000

s

0.001

s

0.000 s

Defines the delay when the status changes from 0 to 1.

DIx Drop-

off time

0.000…1800.000

s

0.001

s

0.000 s

Defines the delay when the status changes from 1 to 0.

DIx AC

Mode

0: Disabled

1: Enabled

-

0:

Disabled

Selects whether or not a 30-ms deactivation delay is added to take the

alternating current into account. The "DIx Release threshold" parameter is

hidden and forced to 10 % of the set "DIx Activation threshold" parameter.

DIx

Counter

0…2

32

–1

1

0

Displays the number of times the digital input has changed its status from

0 to 1.

DIx Clear

counter

0: -

1: Clear

-

0: -

Resets the DIx counter value to zero.

The user can set the activation threshold individually for each digital input. When the activation and

release thresholds have been set properly, they will result in the digital input states to be activated and

released reliably. The selection of the normal state between normally open (NO) and normally closed

(NC) defines whether or not the digital input is considered activated when the digital input channel is

energized.

The diagram below depicts the digital input states when the input channels are energized and de-

energized.

A

AQ

Q-M215

-M215

Instruction manual

Version: 2.04

418